- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » What is Steel Box Section?

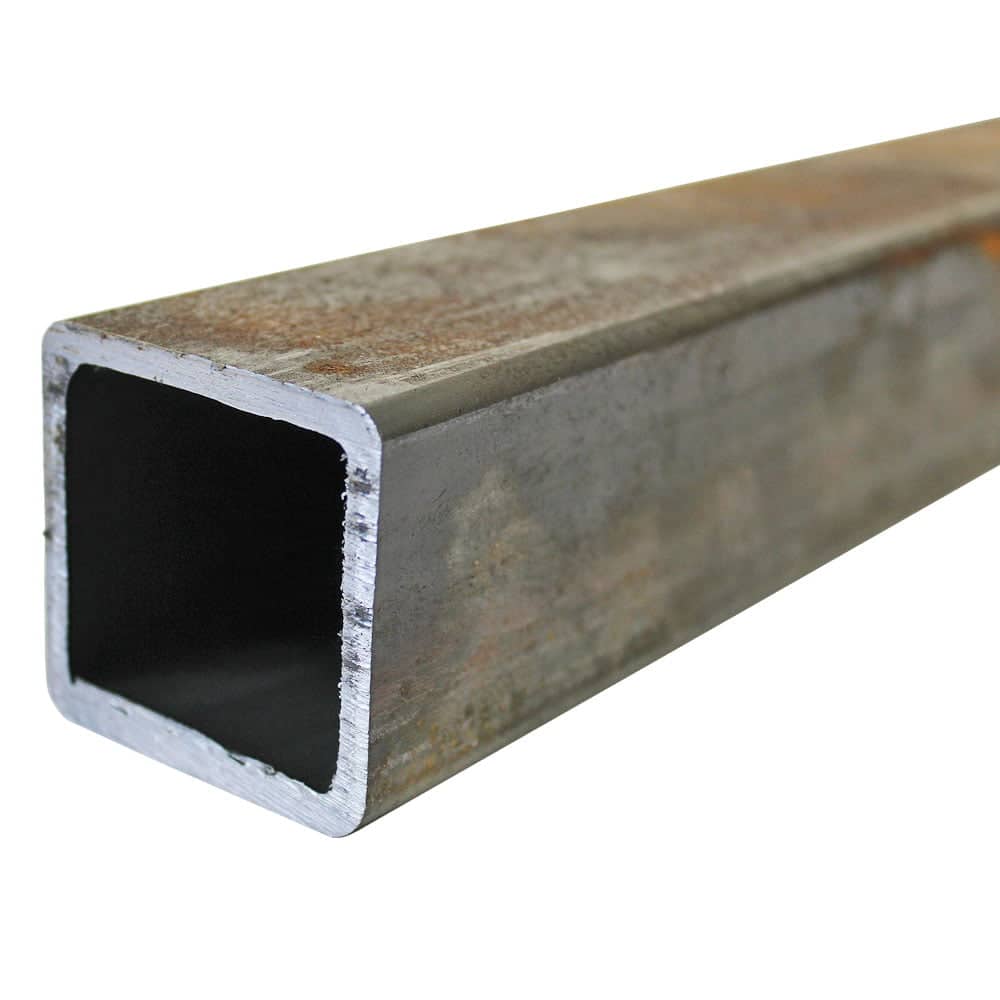

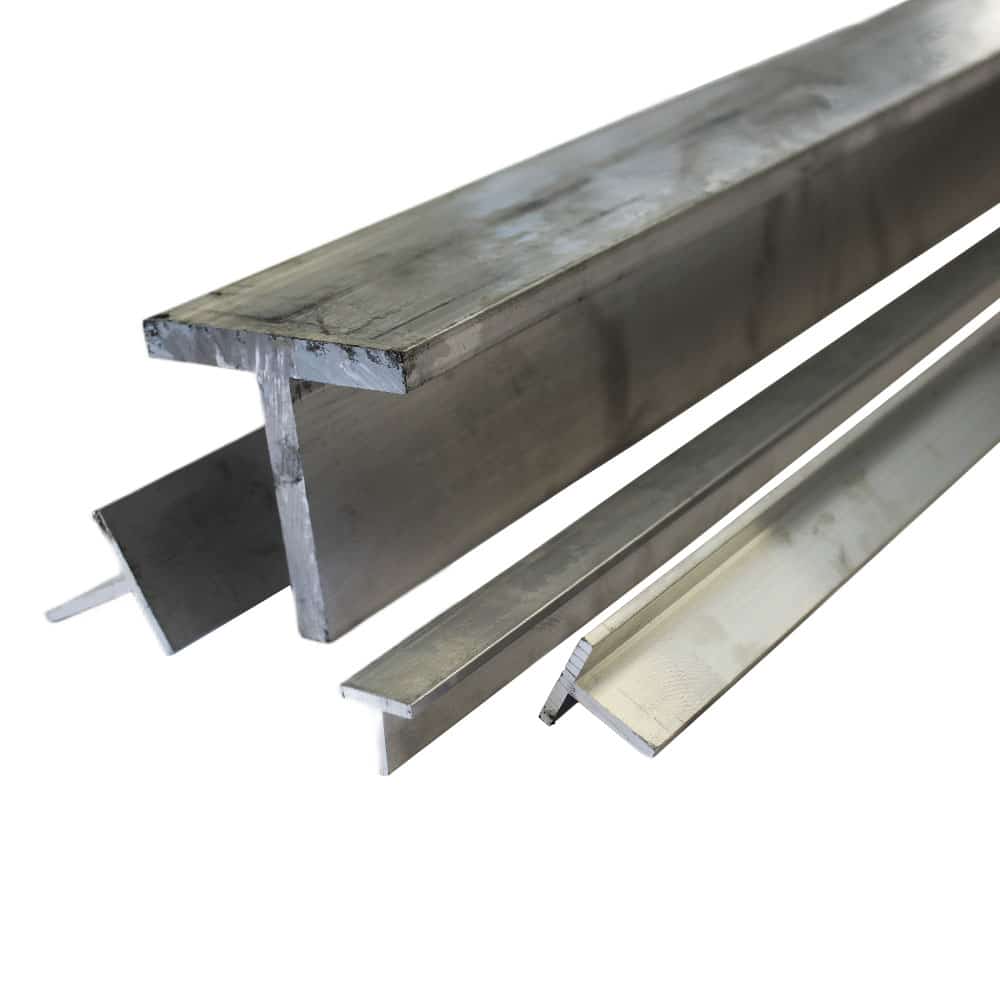

Steel box section, also known as hollow section, is a type of carbon steel and a strong metal construction material usually made from plain mild steel.

Box section made from mild steel is the perfect tool to build with as mild steel has great welding abilities and can easily be bent and formed. It’s also a versatile metal as there are no other alloys apart from a small amount of carbon that’s combined with it therefore you can coatings like paint to it.

Mild steel is also very strong and combined with the durable structure of hollow box section, the material has great reinforcement and it fairly lightweight.

Hollow section is normally made with plain mild steel, however you can also get it in aluminium, galvanised steel and stainless steel. Plain steel is the preferred metal for box section as there is more you can do with it in terms of welding, forming and machining.

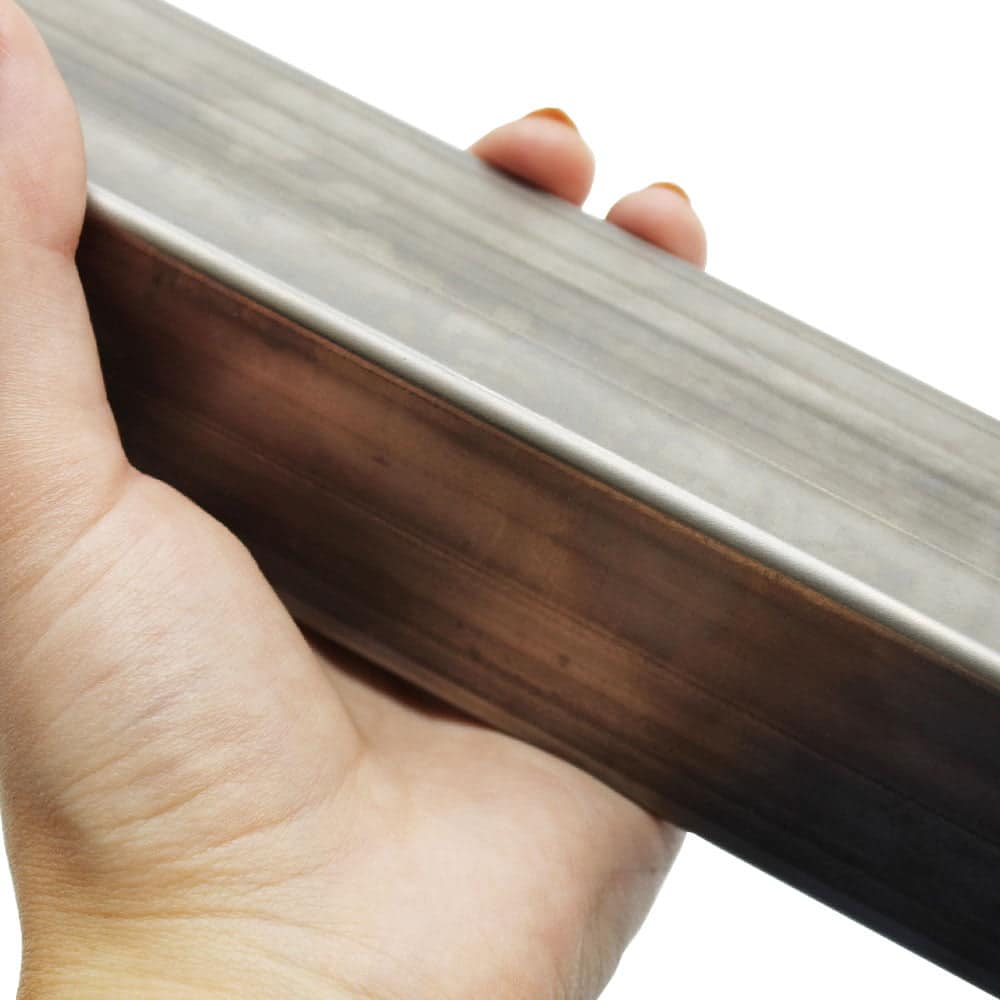

Steel box section begins with a strip of mild steel that can be shaped in two different ways. The first process is by hot rolling the strip of mild steel through a mill. This method heats up the metal to a high temperature of around 1000 degrees so that the metal is malleable. The mill then rolls and bends the strip down the centre at the necessary points to form a square or rectangle shape.

As the metal is heated to such a high temperature, it doesn’t need to be welded together once hot rolled into shape. The heat bonds the ends together and creates a seamless invisible binding.

The other method to create steel box section is the cold rolled process. A similar process is applied to the strip of steel however it is not heated to a high temperature. Because the strip of metal is cold, it makes it harder to bend into the required shape. There is much more effort needed to roll the metal strip thus making it a more expensive and time consuming process.

Once shaped, the metal is then welded at the connecting ends to create a seamless bond. With this, there is the risk of seeing where its been welded however it’s often sanded down so it’s hard to tell.

The hot rolling process is more beneficial firstly because it’s cheaper and less time consuming than the cold rolling process. This is because the metal is heated so it’s more malleable therefore there is a lot less time and labour put into shaping the strip of metal compared to cold rolling. The other benefit is that it doesn’t have to be welded so there is no risk of potentially having a rough edge.

Mild steel box section is used for a variety of applications such as:

Mild steel box section brings many advantages to all kinds of projects such as:

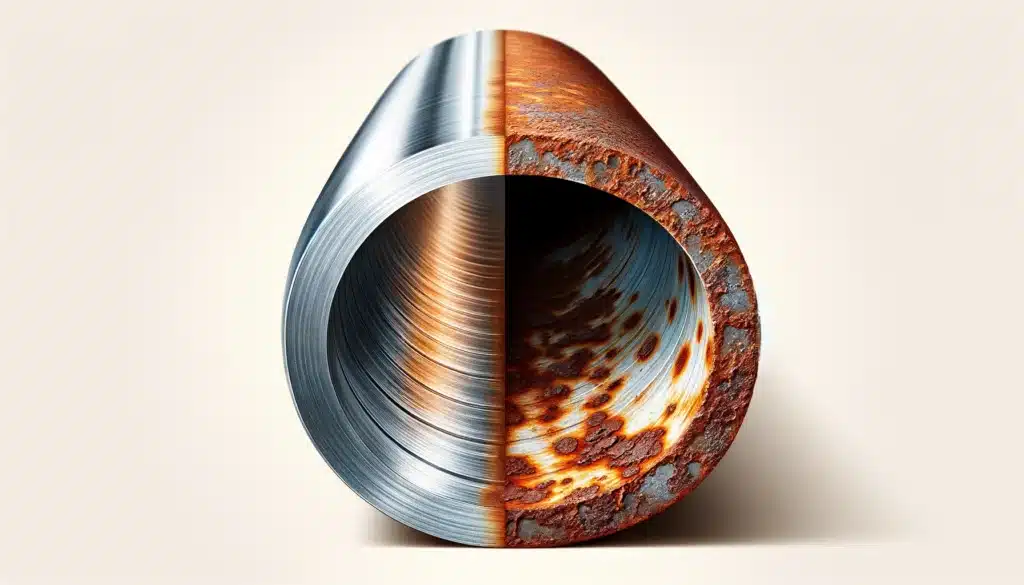

Plain steel does have some disadvantages such as:

Mild Steel, also known as plain steel, is a pure metal alloy with a low carbon content. It’s a strong and versatile material with great welding abilities, perfect for using in construction.

Plain steel has no protective layers therefore you can do lots with it such as painting, bending and forming however it’s a corrosive metal and will rust over time and create a rough surface. Nevertheless, rust can still be removed by fine sanding or using WD40.

If you require a metal that doesn’t rust then it’s recommended to use stainless steel or galvanised steel.

Also, mild steel has magnetic abilities so a magnet will stick to it however mild steel isn’t a magnet itself.

The grade we supply for plain mild steel box section is S235JRH grade. We supply this grade of mild steel as we believe it’s the most functional and beneficial grade. It’s popular and great for everyday construction projects and machinery.

S235JRH grade mild steel has great welding and mechanical properties and doesn’t need any heat treatment. It’s often used for inaugurating solutions in civil engineering. Steel of this grade is also used in oil and gas platforms, building and bridge frames, power transmission towers, residential buildings, steel pipes, vehicle structures, tools and cutters.

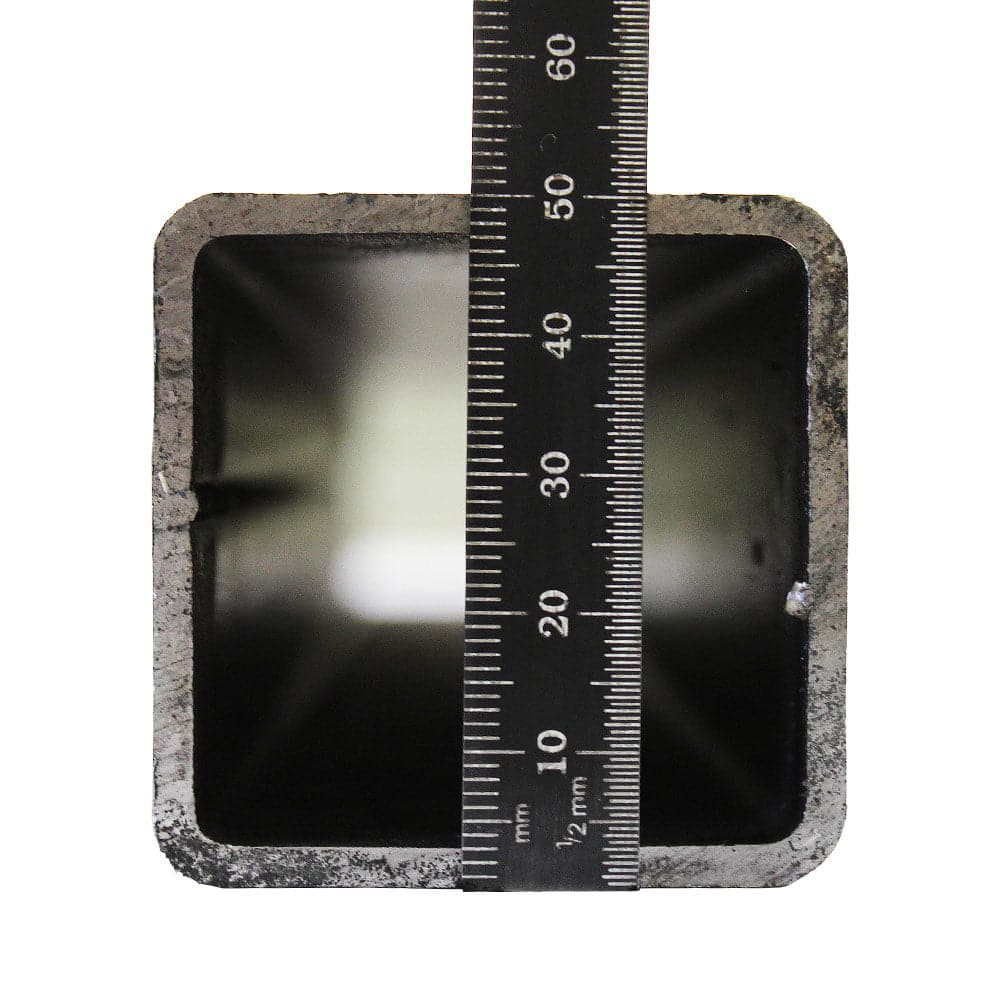

We use a cutting process that involves our ultra-powerful industrial saw. We cut down the mild steel square tubes into smaller lengths with our industrial saw and then we de-burr the ends where possible so there’s no sharp edges.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Our high quality mild steel box section comes in two metre lengths but we cut them down to one metre lengths for storage reasons.

We can cut our box section down to any length you require with our ultra-powerful industrial saw. If we don’t offer the length you need, you can contact us to discuss a bespoke deal.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options