- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » How Do I Bend T Section Aluminium Bar? Techniques and Tips

In order to bend T section aluminium bars, you have to understand both the material’s unique properties and its cross-sectional shape.

With its lightweight and strength, aluminium offers exceptional versatility across a wide range of applications. When it comes to altering its form, especially T section bars, a careful approach is needed to keep the material’s integrity and get the results you want.

Speciality Metals provides T section aluminium bars for a variety of uses, from structural supports in construction projects to intricate details in custom fabrications. Presented in this guide are step-by-step techniques backed up by practical advice to ensure precise and accurate bending of these bars.

The ability to bend T section aluminium bars expands the scope of potential projects and also ensures each undertaking is executed with the utmost precision and quality.

Aluminium has a unique combination of properties: lightness, strength, and malleability. Its inherent flexibility makes aluminium a great material for bending and shaping, a quality that’s heavily influenced by its alloy composition, temper, and thickness. As a malleable material, aluminium can be shaped into a variety of shapes and forms without losing its structural integrity, making it a popular material.

Despite this, bending aluminium, especially T-section bars, requires an understanding of the factors that affect its bendability. As an example, the 1050 grade is known for its excellent formability compared to the 6061 grade, which is stronger but not as flexible. Aluminium’s temper, indicated by letters and numbers, also affects its bendability. In a softer, annealed state (designated as ‘O’), materials are more malleable than those that have been heat-treated for strength.

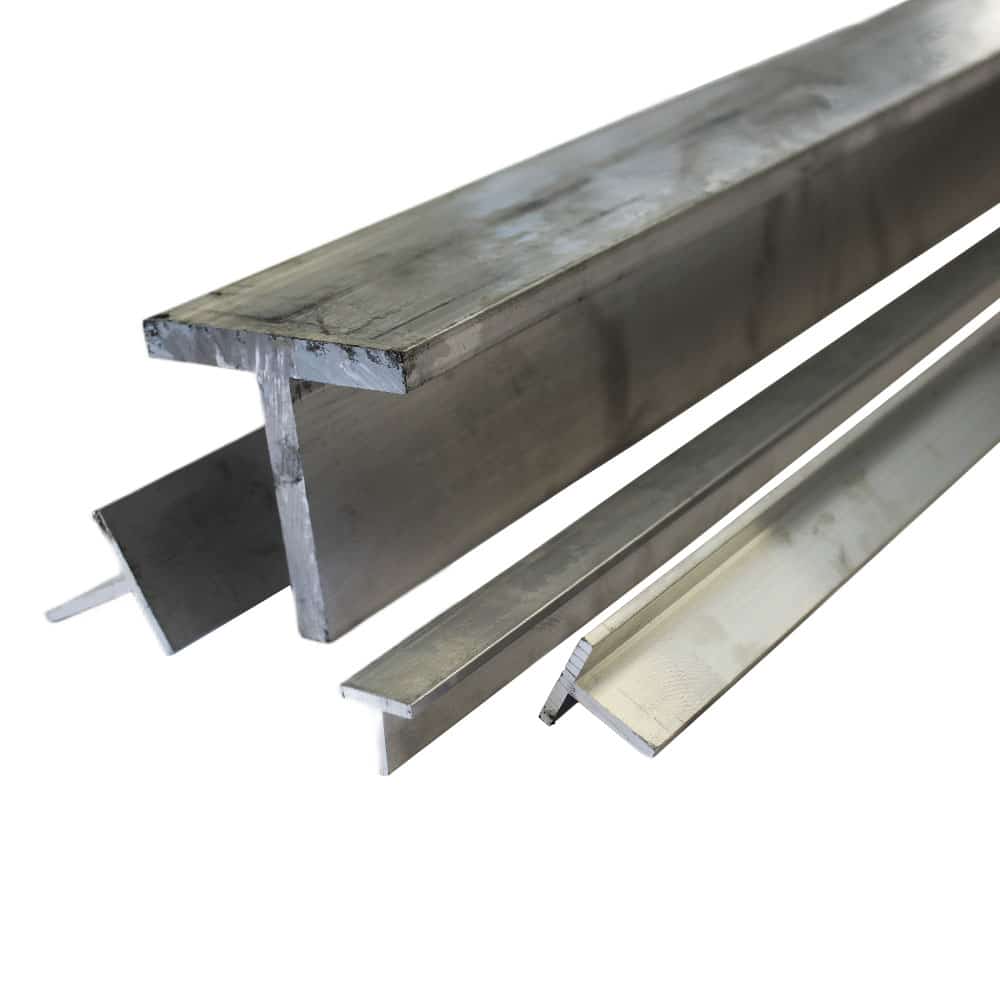

The cross-sectional shape of T-section aluminium bars makes bending them challenging. A ‘T’ shape requires careful geometry to avoid distortion or cracking at the bend. Bars like these are commonly used for structural frames, decorative trims, or if you want a specific aesthetic. The nuances of aluminium’s properties and how T section bars bend are crucial to ensuring that the final product meets both functional and aesthetic needs.

It is necessary to use specific tools and equipment to bend T section aluminium bars, each designed to accommodate the material’s properties. Manual benders are suitable for small-scale or intricate projects, while hydraulic presses and CNC benders are suitable for larger, more industrial jobs.

Manual Benders

Hobbyists and those who need a high degree of precision often choose manual benders. These tools provide direct control over the bending process, but they require physical effort and are best used for thinner T-section bars. Beginners can use them because of their affordability and ease of use. With thicker bars or when multiple bends are required, their limitations become apparent.

Hydraulic Presses

By applying consistent pressure to the aluminium, hydraulic presses offer a more robust solution. They provide the force needed to manipulate thicker T-section bars without causing stress or fractures. During bending, hydraulic presses can achieve precise angles, but custom dies are required to prevent deformation of the T section.

CNC Bending Machines

CNC bending machines are the pinnacle of bending technology, offering unparalleled precision and repeatability. Using these machines, complex bending operations can be performed with minimal setup time. In volume production, they are especially useful for producing consistent bends. CNC machines are primarily justified for high-volume or technically challenging projects because of their cost.

When bending aluminium T sections, safety is paramount. To protect against potential hazards, wear protective gear such as gloves, safety glasses, and hearing protection. It is also important to understand the operating limits of your equipment and to inspect your tools regularly for wear and damage in order to prevent accidents.

Precision and clean bends require proper preparation of T section aluminium bars. The first step is measuring and marking the aluminium bar. Mark where the bends will happen with a fine-point marker and a metal ruler or measuring tape. It’s important to ensure accuracy at this stage.

The next step is to secure the material, so it stays stable during the bending process. Clamp the aluminium bar firmly to the workbench or bending machine, making sure it’s aligned. It prevents slipping or movement that could cause uneven bends.

It can be easier to bend aluminium bar when it’s heated, especially for thicker sections or tighter radii. Heat evenly along the section to be bent can make it more malleable. It’s important to monitor the temperature closely, since overheating can weaken aluminium. For this, you can use a heat gun or propane torch, which applies heat gradually and evenly. Aluminium bends best between 200-350°C (392-662°F), depending on the alloy and temper.

Taking these steps lays the groundwork for successful bending, ensuring the T section aluminium bar is manipulated accurately and safely.

To bend T section aluminium bars, you have to take a nuanced approach that preserves the material’s integrity. Different techniques can be used, depending on the project and the aluminium’s physical properties.

Cold Bending

Cold bending involves manipulating the aluminium bar at room temperature. This technique works for bars with thinner profiles or softer tempers, where the material’s natural flexibility allows for bending without additional heat. Using a bending machine or press that can accommodate the unique shape of the T section is the key to successful cold bending. In order to get precise angles and radii, you have to use bending dies that match the profile of the T section, so the material doesn’t flatten or distort.

Heat Assisted Bending

With Heat-Assisted Bending, aluminium is made more malleable by gentle heat, making it easier to bend thicker or harder T-section bars that may resist cold bending. By softening the aluminium, the risk of cracking or breaking is reduced. Controlling the temperature is important, as excessive heat can weaken the aluminium, while insufficient heat may not provide the desired flexibility. By applying heat uniformly along the bend line, followed by slow and steady pressure, clean bends can be achieved. Temperature can be gauged visually by watching the color of the material, aiming for a warm but not discolored appearance.

Bending Jigs

For repetitive bends or complex shapes, Bending Jigs can ensure consistency and precision. The jig guides the T section aluminium bar into the correct position and angle during bending. It is possible to fabricate custom jigs to match specific project requirements, providing support to the material and reducing slippage and misalignment.

To avoid common bending issues like cracking, overbending, and distortion, several strategies can be employed:

By following these guidelines and techniques, you’ll be able to bend T section aluminium bars precisely, preserving their aesthetics and structural integrity. Fabricators can bend aluminium easily by understanding its properties and applying the right bending method.

When T-section aluminium bars are bent to the desired shape, finishing and post-bending treatments enhance their appearance and properties. Cleaning, polishing, and refining the bent sections are some of the steps in the finishing process.

Finishing Techniques

Remove any debris or lubricant used during bending from the aluminium surface. Surfaces can be cleaned effectively with mild soap and water without damaging the metal. Buff the aluminium gently with a soft cloth or non-abrasive pad to enhance its natural shine. Fine-grit sandpaper can be used sparingly to smooth deeper scratches or blemishes, followed by polishing to restore the surface.

Post-Bending Treatments

Certain post-bending treatments, like annealing, may be beneficial depending on the application. An annealing process involves gently heating bent aluminium to relieve internal stresses, then cooling it down. It can improve ductility and reduce cracking, especially in tight radii. To determine the appropriate temperature and cooling rate for the alloy of aluminium, consult a metal expert or refer to material guidelines.

Correcting Inaccuracies

Despite careful planning and execution, bend angles and radius can be off. Check the dimensions and angles against the specs. By carefully rebending or applying localised pressure, you can often make minor adjustments. For more significant discrepancies, consult a metalworker to figure out how to fix it without compromising the T’s structural integrity.

In the metalworking domain, mastering the art of bending T section aluminium bars requires precision, creativity, and technical expertise. In this comprehensive guide, we have outlined the foundational techniques and considerations for manipulating T section aluminium bars, enabling you to utilise the unique attributes of this material to enhance your projects.

Our goal at Speciality Metals is to provide our clients with not only superior aluminium products but also the guidance and support they need to achieve their goals. Embracing the complexities of bending aluminium opens up a wide range of design and innovation possibilities.

Explore our extensive range of T section aluminium bars and take advantage of our expertise to achieve the full potential of your metalworking projects.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options