- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Powder Coating vs Liquid Painting: What’s Best for Metal Protection?

When it comes to safeguarding metal surfaces, the debate between powder coating and liquid painting is a hot topic among manufacturers, DIY enthusiasts, and professionals in various industries.

There are a number of advantages and limitations to both methods, therefore it is crucial to be able to determine which method provides the best solution for metal protection. In this comprehensive analysis, you will get to know the specifics of powder coating and liquid painting so that you can make an informed decision about which method will suit your needs the best.

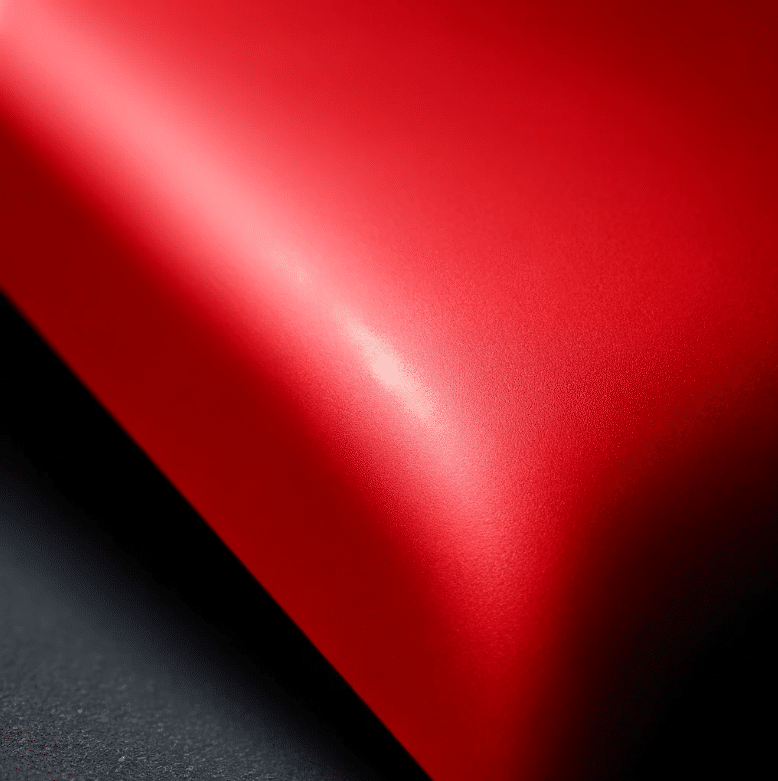

Since its introduction in North America over 40 years ago, powder coating has become increasingly popular. Using an electrostatic process, a dry powder – usually a mixture of finely ground pigments and resins – is applied to a metal surface.

Charged powder particles adhere to electrically grounded surfaces until heated and fused into a smooth coating in the curing oven.

Painting with liquid paint is a method of applying a liquid paint solution – a combination of pigments, solvents, and binders – to a metal surface directly with the help of a brush, roller, or sprayer.

In the process of the solvent evaporating, the paint forms a thin film that adheres to the surface as it evaporates.

Durability is paramount when it comes to protecting metal. Powder coatings provide a robust barrier against harsh conditions, making them ideal for items subjected to extreme weather, chemicals, or mechanical stress. Cured powder coatings also ensure comprehensive coverage, minimising moisture penetration and corrosion risks.

It is often necessary to apply multiple coats of liquid paint in order to achieve the same level of durability as solid paints. In addition, they are prone to chipping and scratching, which can expose the underlying metal.

The application process can have a significant impact on the decision between powder coating and liquid painting. In most cases, powder coating cannot be successfully completed by a DIYer without professional equipment. As a result, it is less accessible for small repairs or on-the-spot maintenance.

In contrast, liquid paint is readily available and can be applied by anyone. Due to its ease of use, it can be used for quick touch-ups or projects where powder coating equipment cannot be set up and cleaned up.

Any protective treatment decision must be based on cost. Due to the need for specific equipment and the possibility of higher material costs, powder coating might initially appear more expensive. Over time, its durability and lower maintenance requirements can save money.

There is no doubt that liquid painting has a lower upfront cost, but it could become more expensive in the long run due to the need for more frequent touch-ups and refinishing, especially in harsh environments.

It is impossible to ignore the environmental impact of each method. As powder coating releases minimal VOCs during application and drying, it is a more environmentally friendly option than liquid painting.

| Metal Type | Powder Coating Suitability | Liquid Painting Suitability |

|---|---|---|

| Stainless Steel SS304 | Good (Durable, less environmental impact) | Limited (Less durable, higher VOCs) |

| Aluminium | Good (Durable, variety of finishes) | Good (Flexible application, vibrant colors) |

| Galvanised Steel | Good (Excellent durability, environmental friendly) | Limited (Prone to inconsistencies) |

| Copper | Not Recommended (Poor adhesion of powder) | Good (Flexible, but less durable) |

| Mild Steel | Good (Excellent durability and coverage) | Limited (Needs frequent touch-ups) |

| Brass | Not Recommended (Poor adhesion of powder) | Good (Flexible, but less durable) |

The decision between powder coating and liquid painting when it comes to metal protection is determined by a number of factors, including the intended use of the item, the desired aesthetic, budget limits, and the environmental conditions in the area.

Powder coating excels in durability, efficiency, and eco-friendliness, making it an ideal choice for long-term metal protection in challenging environments.

It is worth noting, however, that liquid painting remains relevant due to its application versatility and cost efficiency, especially for smaller projects or when the need for quick, on-site repairs arises.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about painting aluminium and maintaining stainless steel recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options