- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » The Handyman’s Helper: Practical Fixes Using Mild Steel Sheet Packs

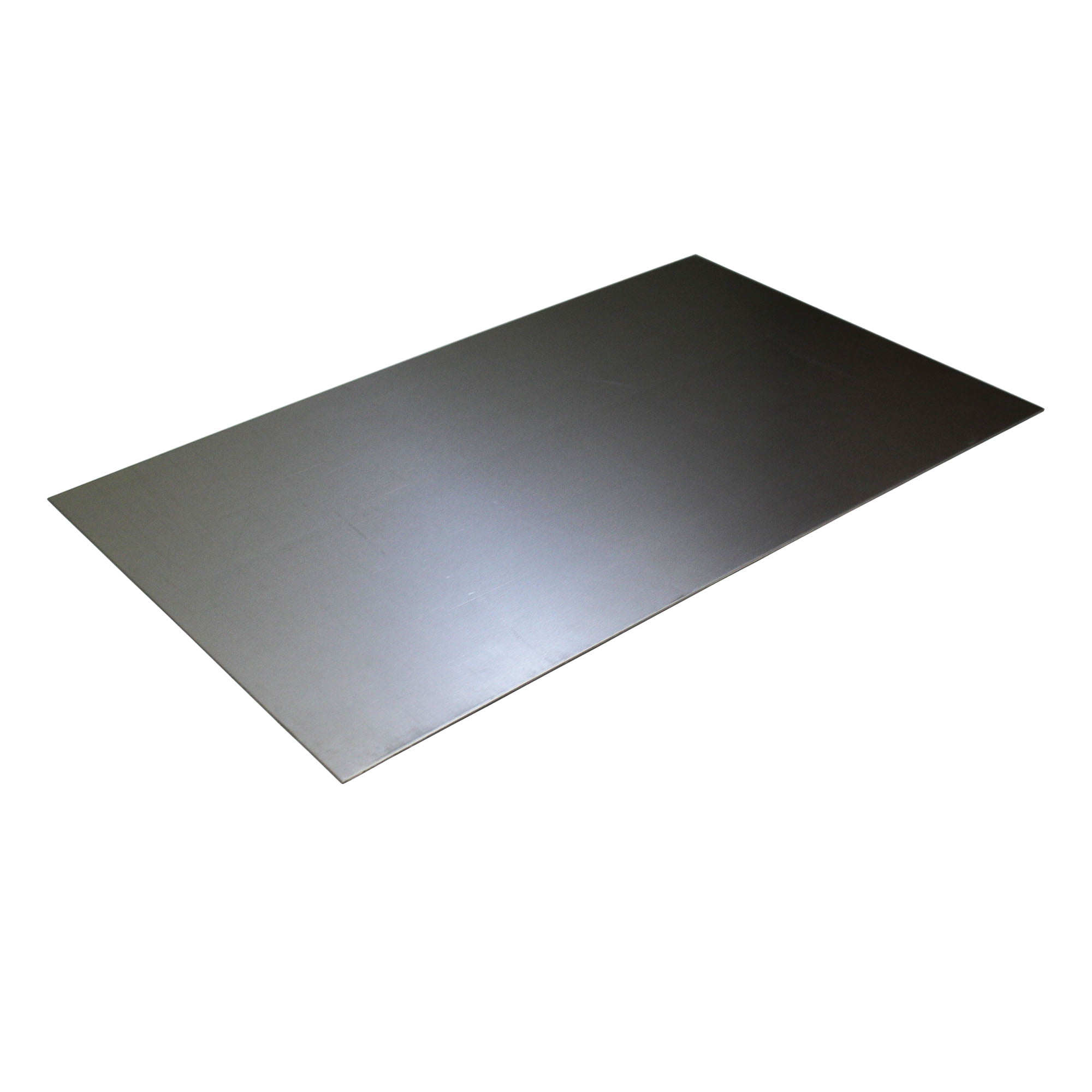

Mild steel, often considered the workhorse of the metal world, is a material that boasts versatility and durability, making it an indispensable ally in the world of home repairs.

You may have noticed that we offer our small sheet options in packs of 2, 3 or 5. We have done this to give our customers the quantity of cuts that are usually required for patch-up jobs in the home, vehicles etc.

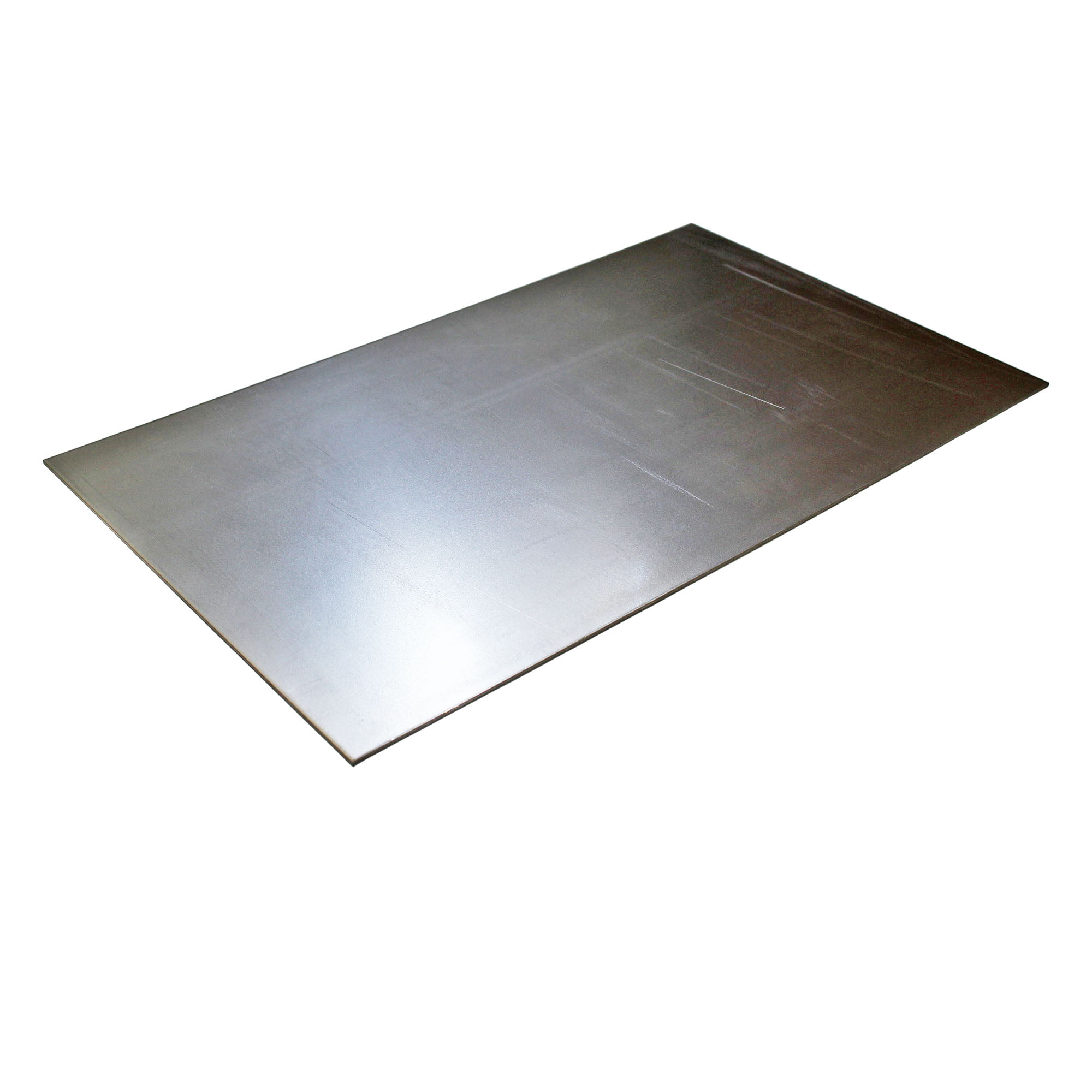

Due to its inherent strength and malleability, it can be shaped, welded, and cut to suit a variety of applications. Mild steel sheets in small pack sizes from Speciality Metals enable quick fixes and creative solutions for a wide range of applications.

Whether you are reinforcing a structure, creating a custom piece, or making precise modifications, these packs ensure you have the right metal.

Let’s go into detail and find out why..

Among DIY repair materials, mild steel stands out for its unique combination of flexibility and toughness. Because this material is easy to use, even novice DIY enthusiasts can work confidently, knowing their repairs will last.

We have a wide range of thicknesses available, from the pliable 0.5mm to the robust 6mm. Each showcases the adaptability of mild steel in their own way.

The thinner sheets, perfect for delicate or intricate repairs, can be easily shaped and are ideal for indoor applications.

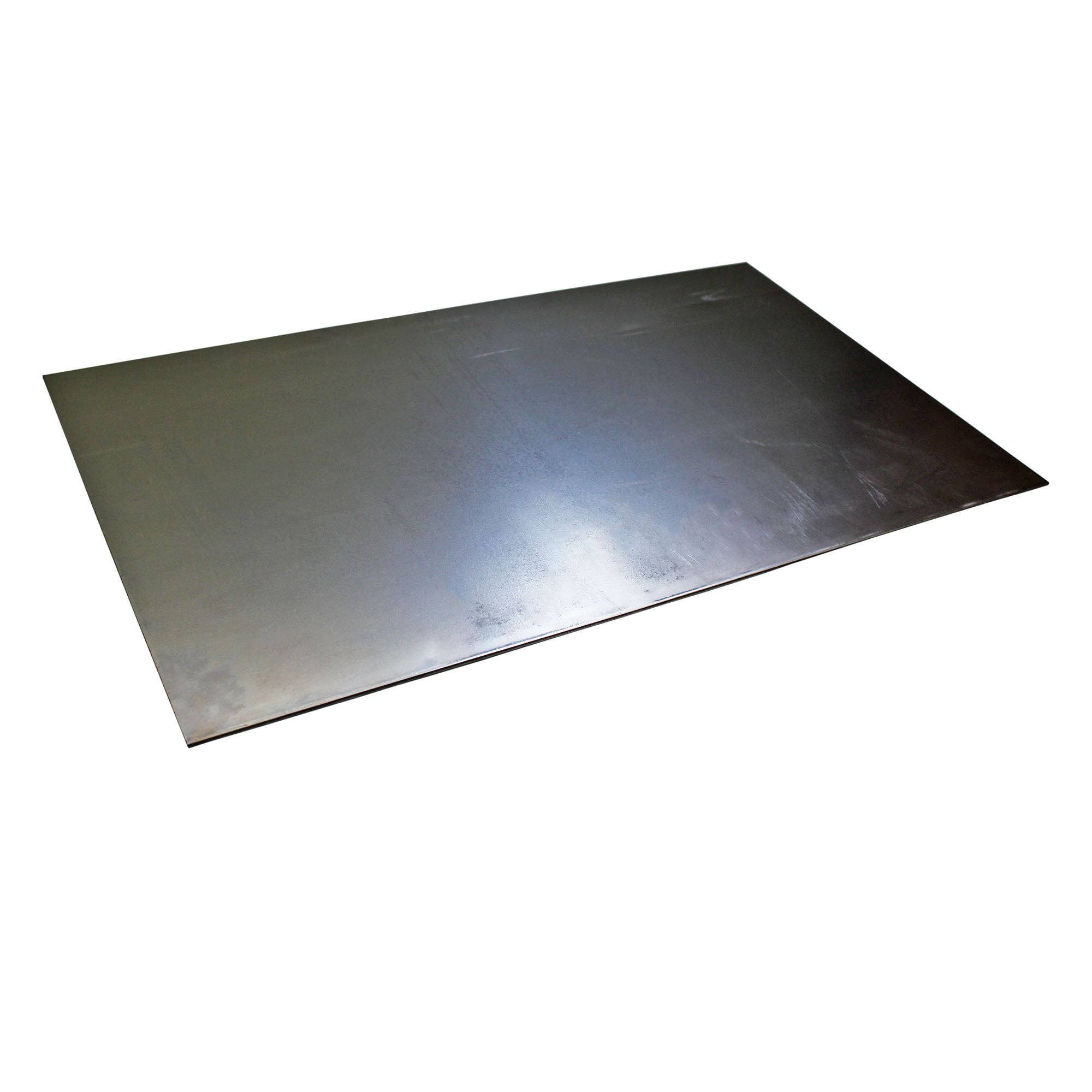

Conversely, the thicker sheets promise the strength needed for outdoor repairs, where resilience against the elements is a must. We find that customers prefer the thicker options for vehicular repair for example.

Speciality Metals provides this versatile spectrum of sizes to ensure that whether you’re patching up a garden tool or creating a weatherproof sign, the material at hand is up to the task.

Mild steel sheets are invaluable in everyday household repairs. Thinner sheets, ranging from 0.5mm to 1mm, are ideal for small repairs, such as sealing gaps in metal fixtures or custom-crafting brackets. The malleability of their materials allows them to be easily manipulated, while their strength ensures they last a long time.

Meanwhile, the 2.5mm to 6mm sheets are ideal for more demanding projects. The thicker options are ideal for reinforcing worn-out areas on metal gates or creating durable surfaces on outdoor furniture. The ease with which these mild steel sheets can be drilled allows for effortless integration into existing structures.

There are a variety of pack sizes available, so you can tackle tasks like repairing a leaking container with a 100mm x 100mm patch, or shoring up a barbecue pit with a 300mm x 300mm plate with confidence, knowing that Speciality Metals’ quality is reliable.

Let’s check out what sizes are available:

A nuanced approach is needed when working with mild steel sheets, especially when considering different thicknesses.

A pair of tin snips or hand shears can be used to cut finer 0.5mm sheets without warping the metal. With thicker sheets, you might need a bench shear or an angle grinder, which provide the necessary force while minimising deformation. A simple vise and hammer can be used to bend thinner sheets, or a sheet metal brake can be used for a cleaner bend.

In order to bend and cut thicker 6mm plates, you’ll need industrial-level equipment such as a press brake and plasma cutter. Thick sheets can be tack welded with a low-amp MIG welder, while thicker plates may require preheating and a more powerful TIG welder.

To avoid compromising the integrity of the metal during your work, you must adjust your techniques according to the thickness.

There are many project possibilities available with Specialty Metals’ mild steel sheet sizes. Patching up holes in metal furniture or small cosmetic repairs on vehicles is easy with the compact 100 x 100mm sheets. Due to their small size, they are ideal for customising metal crafts and even making bespoke jewelry.

Intermediate sizes, like 150 x 150mm and 200 x 200mm sheets, are ideal for strengthening the joints of metal frames or fabricating custom brackets and supports. You can also use them to make personalised nameplates or signs for your home or garden.

In addition to serving as solid bases for heavy-duty machinery, the 200 x 300mm and 300 x 300mm sheets can also replace metal doors and cabinets. These larger sizes can be fashioned into planting boxes or protective garden bed edgings for those with green thumbs. These heavy-duty 3mm to 6mm 100 x 3 packs are perfect for reinforcing load-bearing beams or crafting a resilient workbench top.

When working with metal, safety should always be paramount. Protecting yourself from sharp edges and metal shards requires wearing protective gear, such as gloves and safety glasses. Be sure the area is well-ventilated when cutting or welding to avoid inhaling metal fumes, and wear ear protection during high-decibel operations.

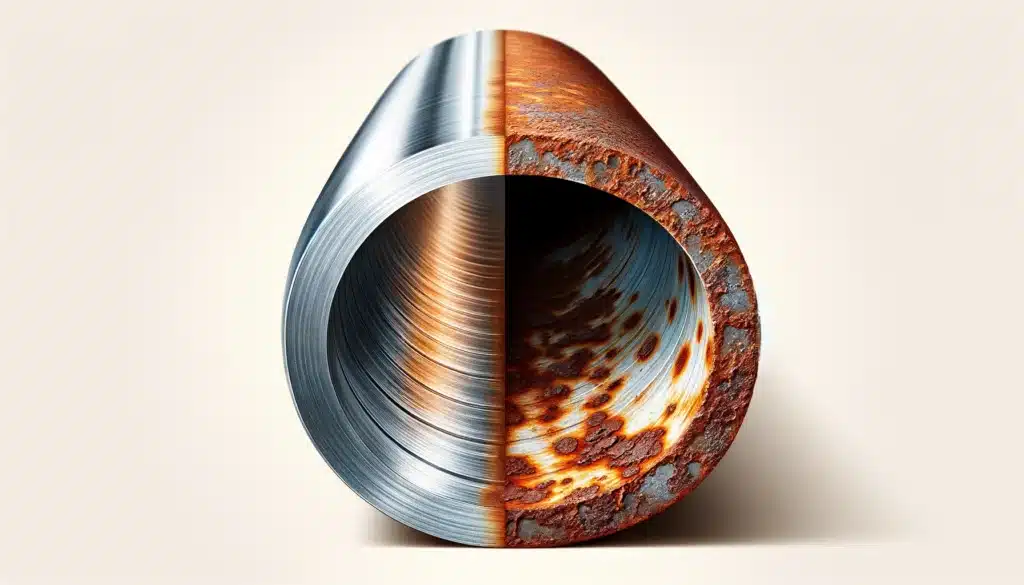

Mild steel sheets should be stored in a dry, covered area to prevent corrosion and surface damage. Apply a light oil or rust-preventative spray for longer-term storage, especially if the sheets are thinner and prone to warping. Dry your sheets immediately if they come into contact with moisture.

The maintenance of your steel repairs is just as crucial. You can detect early signs of wear or corrosion with regular inspections, allowing you to take action before problems escalate. For painted or coated steel, check for chips or scratches periodically and touch up as needed.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options