- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Maximising Efficiency with Butterfly Nuts: A Comprehensive Guide to Sizes and Applications

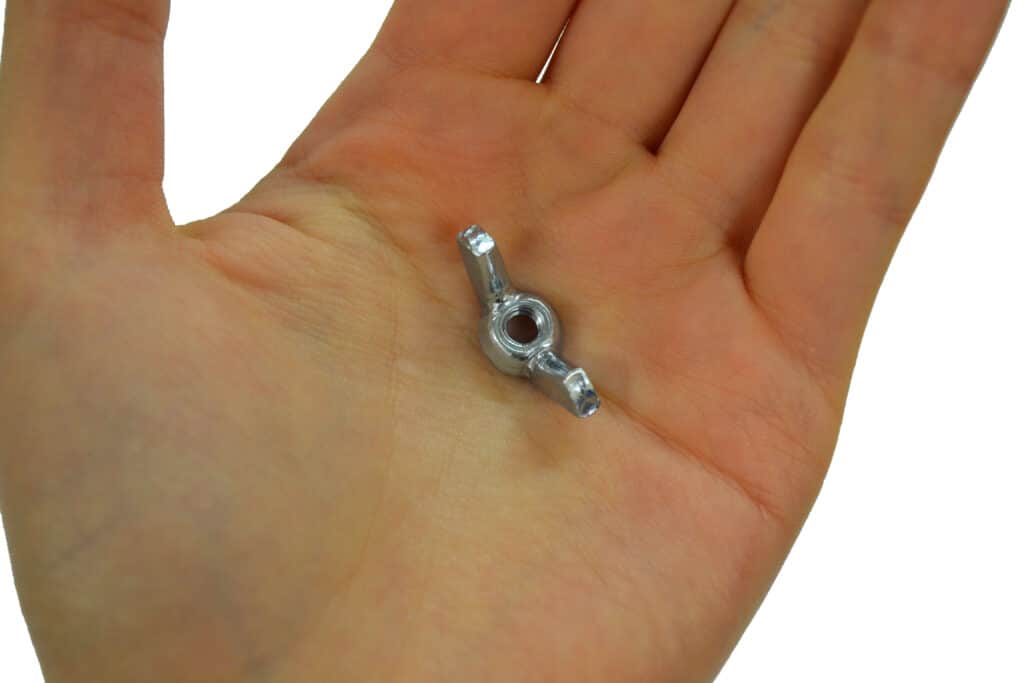

With their two large, wing-like projections, butterfly nuts are easy to tighten and loosen by hand, eliminating the need for tools.

Zinc-plated butterfly nuts are available from Speciality Metals, enhancing their durability and corrosion resistance. Due to their versatility, they are indispensable in both professional and personal settings.

Throughout this blog, we will explore the various sizes available, from M3 to M12, and highlight the added value of zinc plating for extended nut life and enhanced performance.

Let’s get into it..

Butterfly nuts are unique in the fastener world, characterised by “wings” that allow manual adjustment without the use of tools. A practical solution for applications where frequent adjustments are required, or where space constraints make the use of tools impractical, this design is more than just about convenience.

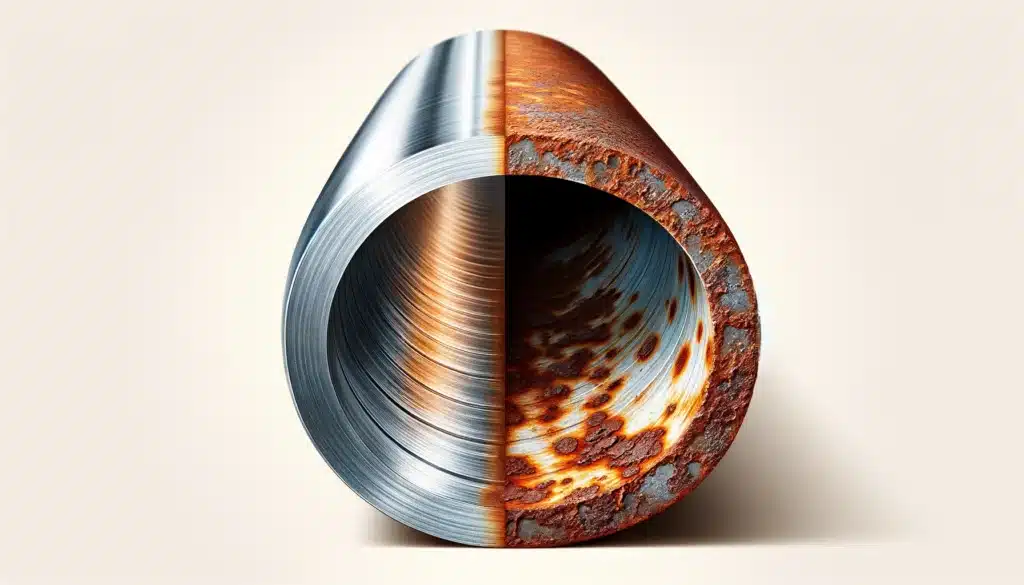

Speciality Metals’ zinc-plated butterfly nuts offer more than just aesthetic appeal. Providing a barrier against moisture and oxygen, two elements that can lead to corrosion, it plays a crucial role in extending the lifespan of nuts. In rusty environments, zinc acts as a sacrificial anode, corroding in place of the metal it protects.

Their ease of use and reliable grip make butterfly nuts a favorite for a wide range of projects. A butterfly nut can be used to secure components in machinery, assemble furniture, or use in arts and crafts applications. No matter what your project requires, Speciality Metals has a butterfly nut that’s suited to it thanks to its durable zinc coating.

Zinc-coated butterfly nuts are available in a variety of sizes to meet a wide range of needs. Whether it’s delicate electronics or robust construction projects, the size of the nut determines its suitability and performance. The following is a breakdown of the different sizes available at Specialty Metals, ranging from M3 to M12.

Designed with specific uses in mind, Speciality Metals’ zinc-coated butterfly nuts come in a variety of sizes, so there is a nut that fits your needs perfectly, whether you are working on sensitive electronic equipment or constructing an outdoor structure. They can be used across a wide range of industries and hobbies, including automotive repairs, electronic assemblies, furniture making, and gardening. Selecting the right butterfly nut for your project depends on understanding the particular utility of each size.

Proper selection and installation of butterfly nuts are crucial for the success and longevity of your projects. Here are some tips and best practices to ensure a secure and effective application:

Matching Nut Sizes to Bolts: It’s imperative to select butterfly nuts that match the diameter and thread count of your bolts. This compatibility ensures a snug fit, preventing the nut from loosening over time.

Avoid Over-tightening: While butterfly nuts are designed for hand tightening, applying excessive force can strip the threads or damage the nut. Tighten until you feel resistance, then give a slight additional turn to secure.

Use with Washers: For added stability and to distribute the load more evenly, pair your butterfly nuts with appropriate washers. This practice is especially recommended for applications where the nut will bear significant weight or vibration.

Regular Inspection: Periodically check the tightness of butterfly nuts in applications prone to vibration or frequent use. Their ease of adjustment means they can also loosen over time, necessitating a quick hand-tighten.

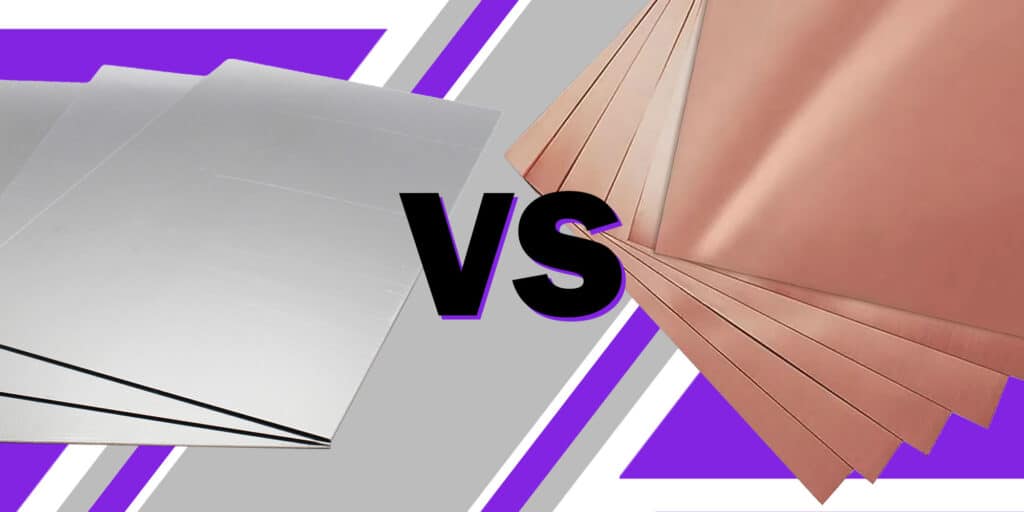

Material Compatibility: Ensure that the material of the bolt is compatible with the zinc-coated butterfly nut to prevent galvanic corrosion. This is particularly important in outdoor or harsh environments.

Zinc plating offers several benefits that enhance the performance and lifespan of butterfly nuts:

Corrosion Resistance: Zinc plating has the primary advantage of resisting corrosion. Over time, zinc acts as a sacrificial layer, corroding slowly and protecting the underlying metal. Zinc-plated butterfly nuts are ideal for outdoor applications or moisture-prone environments.

Enhanced Durability: Additionally, zinc plating increases the durability of butterfly nuts by adding a layer of hardness. As a result of the protective coating, the nuts can withstand regular use without significant wear.

Aesthetic Appeal: An aesthetically pleasing finish is provided by zinc plating. With their neat and professional appearance, zinc-plated butterfly nuts are suitable for visible parts of a project.

Suitability for Various Environments: With their enhanced durability and corrosion resistance, zinc-plated butterfly nuts can be used indoors and outdoors. In any DIY project, garden construction, or automotive repair, these nuts retain their integrity and appearance.

Zinc plating allows butterfly nuts to be more adaptable and reliable for a wide range of applications, ensuring that your projects remain secure and maintain their aesthetic appeal.

With their unique design and ease of use, butterfly nuts open up a world of creativity beyond their conventional uses. Adding both functionality and aesthetic appeal to DIY projects, artistic creations, and home décor, they can become key elements. Create wall art that integrates zinc-coated butterfly nuts as focal points in a larger metal mosaic by using various sizes of zinc-coated butterfly nuts from Speciality Metals.

For custom-built machinery or prototypes, butterfly nuts offer the advantage of quick adjustments without the use of tools. For artists and inventors who constantly tweak their creations, this feature is particularly useful. As adjustable joints, they can also be used in custom lamp stands, bookshelves, and interactive art installations, allowing users to move and modify them.

The industrial aesthetic and practicality of repurposing butterfly nuts as key hooks appeals to home décor enthusiasts. By embedding them in resin, you can create unique drawer pulls or cabinet knobs for your furniture.

From the petite M3 to the substantial M12, butterfly nuts demonstrate the flexibility and convenience inherent in such a simple fastening solution. With a diverse range of sizes and durable zinc coatings, Speciality Metals ensures there’s a butterfly nut for every project.

In our next project, we encourage our readers to think beyond the traditional, to explore the vast potential uses of butterfly nuts. Our selection is designed to meet your requirements with reliability and style, whether they are for practical applications or inventive creations.

Let us know how you use butterfly nuts in your innovative projects.

Please contact us if you require any further assistance with any of our materials.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about nyloc nuts and dome nuts recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options