- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » The Sustainability of Metal: Eco-Friendly Manufacturing and Recycling

In today’s rapidly evolving world, the emphasis on sustainability and eco-friendliness is more pressing than ever. One of the major focuses of this effort is the materials we use every day, and metal stands out as a prime example. From its extraction to final disposal, the sustainability of metal is crucial for the well-being of our planet. Explore this fascinating topic in greater detail and discover why metal’s sustainability deserves our attention.

Metals have played a pivotal role in the annals of human history, acting as signposts for different epochs of our civilisation. Their discovery and utilisation marked transformative eras that significantly shaped human progress. Beginning with the Copper Age around 10,000 years ago, humanity learned to extract and shape this malleable metal, and its alloy, bronze, would later give its name to an entire age of human development. The subsequent Iron Age, beginning around 1200 BC, was characterised by the smelting of iron and its alloys, which proved to be stronger and more durable than their predecessors, thus revolutionising tools, weaponry, and construction methods.

Fast forward to modern times, metals are integral to our daily lives and have expanded far beyond just copper and iron. Aluminum, a metal once more valuable than gold due to the difficulty of its extraction, is now used ubiquitously in everything from aircrafts to soda cans, thanks to advanced refining methods. Precious metals like gold, silver, and platinum are coveted not just for jewelry, but also play crucial roles in electronics and catalysts in various chemical processes. Rare earth metals, a group of 17 elements, are essential components in our modern gadgets, renewable energy solutions, and even defense equipment. The versatility and diverse properties of metals have made them indispensable in the modern world, bridging their rich history to an array of contemporary applications.

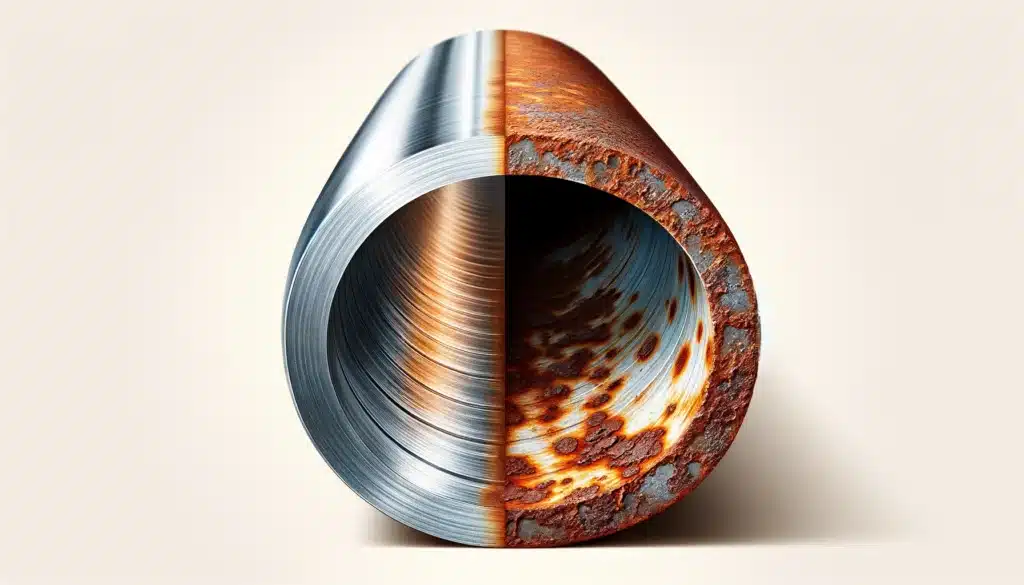

Traditional metal manufacturing has historically carried a hefty environmental toll. The extraction, smelting, and refining of metals in bygone eras were energy-intensive processes, often reliant on the burning of fossil fuels. This not only led to significant greenhouse gas emissions but also to the release of harmful pollutants into the atmosphere, soil, and water. Mines, especially those without proper management strategies, would scar landscapes, cause habitat destruction, and often contribute to water pollution due to runoff. Acid rain, a byproduct of sulfur dioxide and nitrogen oxide emissions from smelting, wreaked havoc on ecosystems and built structures.

However, the transition into the era of modern metal manufacturing has seen a considerable mitigation of these adverse effects. Contemporary processes are increasingly energy-efficient, with a growing reliance on renewable energy sources. Innovations like electric arc furnaces for steel production or inert anode technology for aluminum production significantly reduce CO2 emissions. Moreover, stringent environmental regulations and a heightened corporate emphasis on sustainability have led to enhanced waste management, water recycling systems, and habitat restoration efforts post-mining. While challenges remain, the trajectory of modern metal manufacturing is undeniably more environmentally considerate than its traditional counterpart.

The sustainability of metal begins with how it’s produced. Innovative techniques and technologies are now transforming the industry:

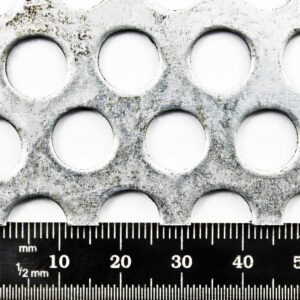

Recycling and Reuse: Encourage the recycling of metals, as they can often be recycled indefinitely without loss of quality.

Sustainable Mining: Adopt mining practices that cause minimal disruption to the environment, like in-situ leaching or using biotechnologies for metal extraction.

Energy Efficiency: Transition to energy-efficient production methods, and use renewable energy sources for metal processing and extraction.

Waste Reduction: Implement technologies that capture and reuse waste products from metal production processes.

Reduce Consumption: Encourage the design and manufacture of products that use less metal or substitute with sustainable alternatives where possible.

Improved Product Design: Design products for longevity and durability, reducing the need for frequent replacement and, consequently, metal demand.

Innovation in Material Science: Research and develop alloys that maintain strength but reduce the quantity of rare or environmentally-taxing metals needed.

Water Conservation: Implement water-saving techniques in mining and processing plants, and recycle or treat wastewater to reduce environmental impacts.

Transparent Supply Chains: Ensure that metals are sourced ethically, and the entire supply chain is transparent and sustainable.

Regulation and Certification: Governments and industries can work together to create regulations and certification programs that ensure sustainable practices.

Education and Training: Invest in educating industry professionals about sustainable practices and train them in their implementation.

Research & Development: Dedicate resources to discovering new sustainable methods and technologies for metal extraction, processing, and use.

Alternative Extraction Methods: Explore less invasive extraction methods, such as bioleaching, where bacteria are used to extract metals.

Land Restoration: Once mining is completed, efforts should be made to restore the mined land to its natural state or repurpose it beneficially.

Community Engagement: Involve local communities in decision-making processes about mining and metal production, ensuring their needs and concerns are addressed.

One of the significant advantages of metals is their recyclability. Unlike some materials that degrade in quality when recycled, metals can be recycled indefinitely without any degradation in properties. This characteristic plays a crucial role in the sustainability of metal.

Conservation of Resources: Recycling metal reduces the need to mine virgin ore. This not only preserves natural resources but also minimises the environmental degradation associated with mining activities.

Energy Savings: Producing metals from recycled materials requires significantly less energy compared to extracting and processing them from raw ore. For example, recycling aluminum saves up to 95% of the energy required to produce the same amount from bauxite.

Emission Reduction: Since recycled metal production is less energy-intensive, it leads to a marked decrease in greenhouse gas emissions. This helps in combating climate change and reducing air pollution.

Economic Benefits: Metal recycling is a major industry that creates numerous jobs. Moreover, using recycled metals can lead to cost savings for manufacturers.

Waste Reduction: Using recycled metals reduces the volume of waste sent to landfills. This not only conserves land but also reduces the environmental impacts associated with waste disposal.

Limiting Toxic Runoff: Mining can result in toxic runoff which can pollute local water sources. By reducing the need for new mines through recycling, we can mitigate this issue.

Preservation of Habitats: Mining often results in habitat destruction. By relying more on recycled metals, there’s a reduced need for new mining projects, hence fewer habitats are threatened.

Sustainable Growth: As demand for metal continues to rise with global development, recycling ensures that supply needs can be met without excessively depleting the planet’s natural resources.

Reduction of Land Degradation: Mining frequently involves stripping vast amounts of topsoil, leading to land degradation. Using recycled metals reduces the scale of such activities.

Mitigating Water Pollution: Metal production from virgin ore can result in water pollution due to the release of processing chemicals. Recycled metal processing typically involves fewer chemicals, reducing the potential for water pollution.

Governments and industries across the globe have come to acknowledge the multifaceted advantages of metal recycling, both from environmental and economic standpoints. In response to this growing awareness:

Infrastructure Development: Significant strides have been made in bolstering the infrastructure that underpins metal recycling. This encompasses not only the establishment of more accessible collection centers but also the introduction of state-of-the-art processing plants equipped with cutting-edge sorting technologies. These advancements aim to streamline the recycling process, making it more efficient and less resource-intensive.

Regulations and Incentives: Policy frameworks in various countries now reflect a proactive stance towards sustainable metal management. A plethora of regulations has been enacted to not just promote but, in some cases, mandate recycling. Beyond the regulatory stick, governments are employing the carrot approach by offering financial and non-financial incentives. These may include tax breaks, subsidies, or even preferential market access for businesses that adopt and advocate sustainable practices in metal usage and recycling.

Public Awareness: Recognising that the success of recycling endeavors hinges on public participation, there has been a concerted effort to enlighten the masses. Educational campaigns, school programs, and public service advertisements are now commonplace, aiming to demystify the recycling process and underscore its pivotal role in the sustainability of metal. Such initiatives are designed to catalyse behavioral change, encouraging individuals to take an active part in recycling and fostering a culture of sustainability.

Furthermore, Collaborative Efforts: Many governments and businesses are joining hands with environmental NGOs and research institutions to further the cause of metal recycling. These partnerships often lead to the pooling of resources, knowledge sharing, and the formulation of holistic strategies that address the challenges of recycling from multiple angles.

While the advantages of sustainable metal manufacturing and recycling are evident, challenges remain:

Collection and Sorting: Different metals require different recycling processes. Efficiently collecting, sorting, and separating metals is crucial but can be resource-intensive and challenging, especially with mixed or complex waste streams.

Contamination: Recycled metal can get contaminated with other metals or impurities. For instance, the mixing of steel with a small amount of copper during recycling can degrade the steel’s properties.

Technology Limitations: Some metals and their alloys present challenges in recycling due to technological limitations in efficiently separating and processing them.

Economic Viability: The economic feasibility of recycling certain metals depends on market prices. When virgin metals are cheaper due to market fluctuations, recycling becomes less economically attractive.

Lack of Infrastructure: In many regions, there is a lack of infrastructure for collecting and recycling scrap metal, especially for rare and specialty metals.

Loss of Material: No recycling process is 100% efficient. Some amount of metal is lost at each recycling cycle, whether as slag, dust, or other forms.

Initial Costs: Establishing modern recycling facilities requires significant investment. In areas where recycling is not yet widespread, the initial costs can be a deterrent.

Regulatory Hurdles: Different regions have varying regulations concerning metal recycling, complicating processes for global or national companies and potentially inhibiting efficient recycling practices.

Public Awareness: Many people remain unaware of the importance of recycling or the correct methods to recycle. This can lead to reduced recycling rates or contamination of recyclable materials.

Transportation Issues: Moving scrap metal to recycling facilities can be energy-intensive, offsetting some of the environmental benefits of recycling.

Complex Products: Modern electronics and other products often contain a mix of metals in tiny amounts or complex arrangements, making them difficult to recycle.

Health and Safety Concerns: Recycling metals can sometimes introduce health and safety issues, especially if metals are contaminated with toxic substances or if the recycling process itself produces harmful byproducts.

The sustainablility of metal is not only a concern for the environment, but also for the economy and society. Since metals are increasingly used for a wide range of applications, we must prioritise sustainable practices at every step. It is possible to ensure that metals continue to serve us without compromising the health of our planet by implementing eco-friendly manufacturing methods or by promoting recycling.

Investing in metal sustainability not only protects our environment, but also ensures a resilient and sustainable future for today’s and tomorrow’s generations.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about ‘Metal Safety: Proper Handling and Storage Tips‘ and ‘Recycle Metal: A Step Toward a Greener Tomorrow‘ recently so why not check them out?

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options