- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

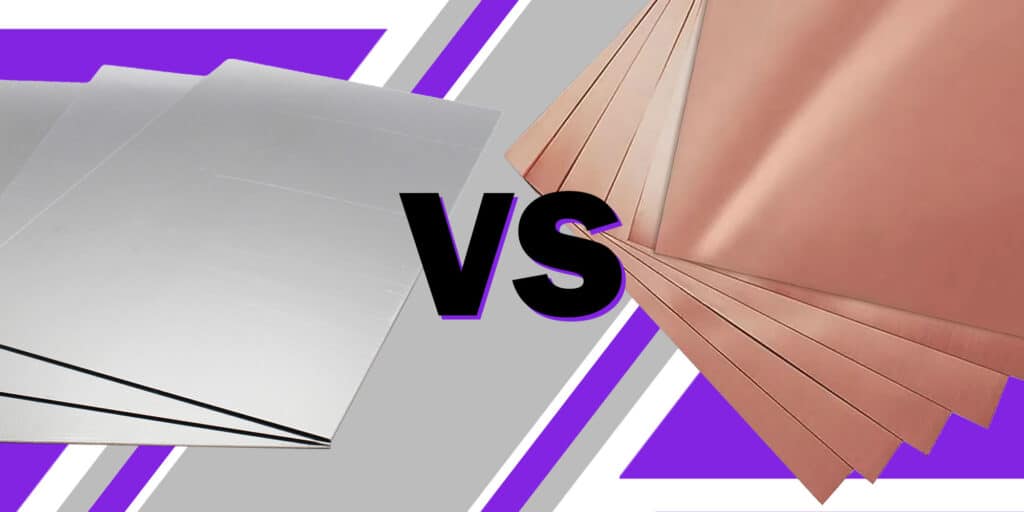

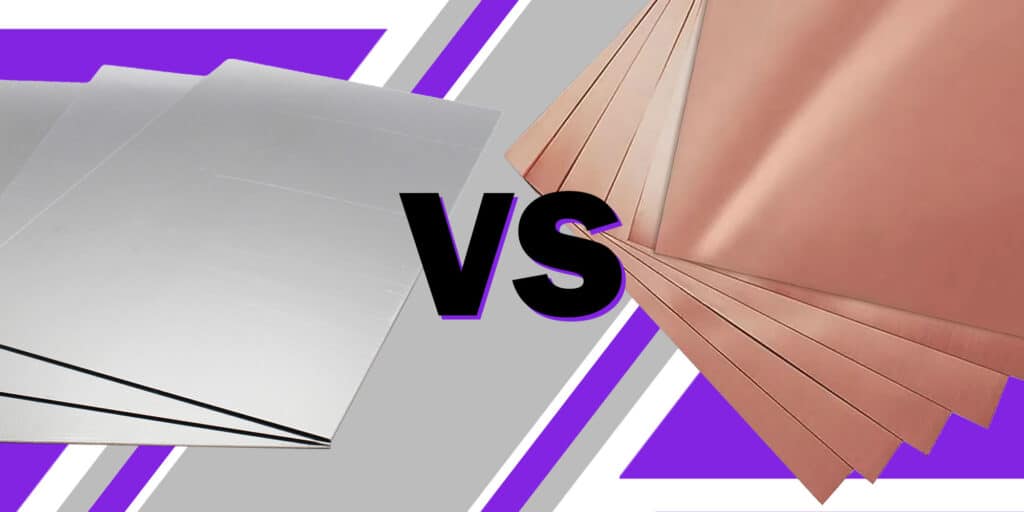

Home » Aluminium vs Copper: Conductivity Wars for Electrical Applications

When it comes to electrical applications, the debate between aluminium vs copper as the material of choice for conductors is a longstanding one.

Each metal offers unique advantages and disadvantages that make them suitable for different applications. In this comprehensive blog post, we’ll delve deep into the properties of both aluminum and copper to determine which metal reigns supreme in the realm of electrical conductivity.

An electric conductivity is a measure of how well a material is able to conduct an electric current. In metals, this property is mostly dependent on the presence of free electrons that are able to move freely through the materials due to their ability to move freely.

Generally speaking, the better the conductivity of a material, the more effectively it will be able to transmit electrical energy with a minimum amount of energy loss. Aluminum and copper are two of the most commonly used conductive materials in the electrical industry, and both of them have inherent characteristics that affect their performance in a wide variety of applications.

As a result of its excellent conductivity, copper has long been the preferred material for electrical applications. Other conductive materials are measured by this standard, often referred to as 100% IACS (International Annealed Copper Standard).

The advantages of using copper in electrical applications include:

Despite its advantages, copper has some limitations:

Aluminium is often considered the second-best option when it comes to electrical conductivity. It has about 61% of the conductivity of copper but offers its own set of advantages:

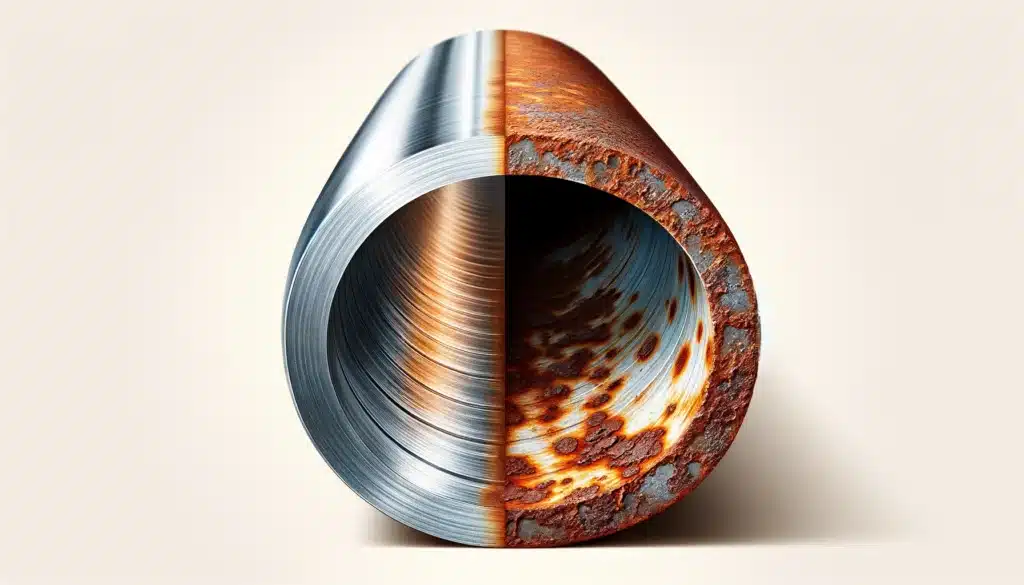

However, aluminum is not without its drawbacks:

When weight and cost are paramount, aluminum is often the preferred material for power transmission lines. Aluminum’s light weight reduces the load on support structures and the foundation, which can reduce installation costs.

Copper is generally preferred in residential and commercial buildings due to its high conductivity, which allows thinner wires to be used. This application requires long-term reliability, which copper’s flexibility and durability make it ideal.

In applications requiring high-frequency signals, such as telecommunications equipment, copper’s superior conductivity makes it the material of choice. For the same conductivity, aluminum wires can cause more signal loss due to their larger diameters.

For electrical applications, the choice between aluminium and copper depends on factors such as cost, weight, conductivity, and environmental conditions. While copper stands out in terms of performance, aluminum’s affordability and light weight make it a compelling option for large-scale uses, particularly where higher costs of copper can be prohibitive.

Ultimately, the conductivity wars between aluminium and copper will continue to evolve as technology evolves and new alloys and processing techniques are developed that enhance their electrical properties.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about painting aluminium and welding copper recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options