- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

£8.29 – £19.58 inc VAT

This website is secured:

£ MULTIBUY SAVINGS – Order 3 For 10% Off

✔ Specialists In Rapid Shipments Of Any Size

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

£ Check Out Our Clearance Listing For Savings

@ ☏ Bespoke Cuts & Larger Quantities Available

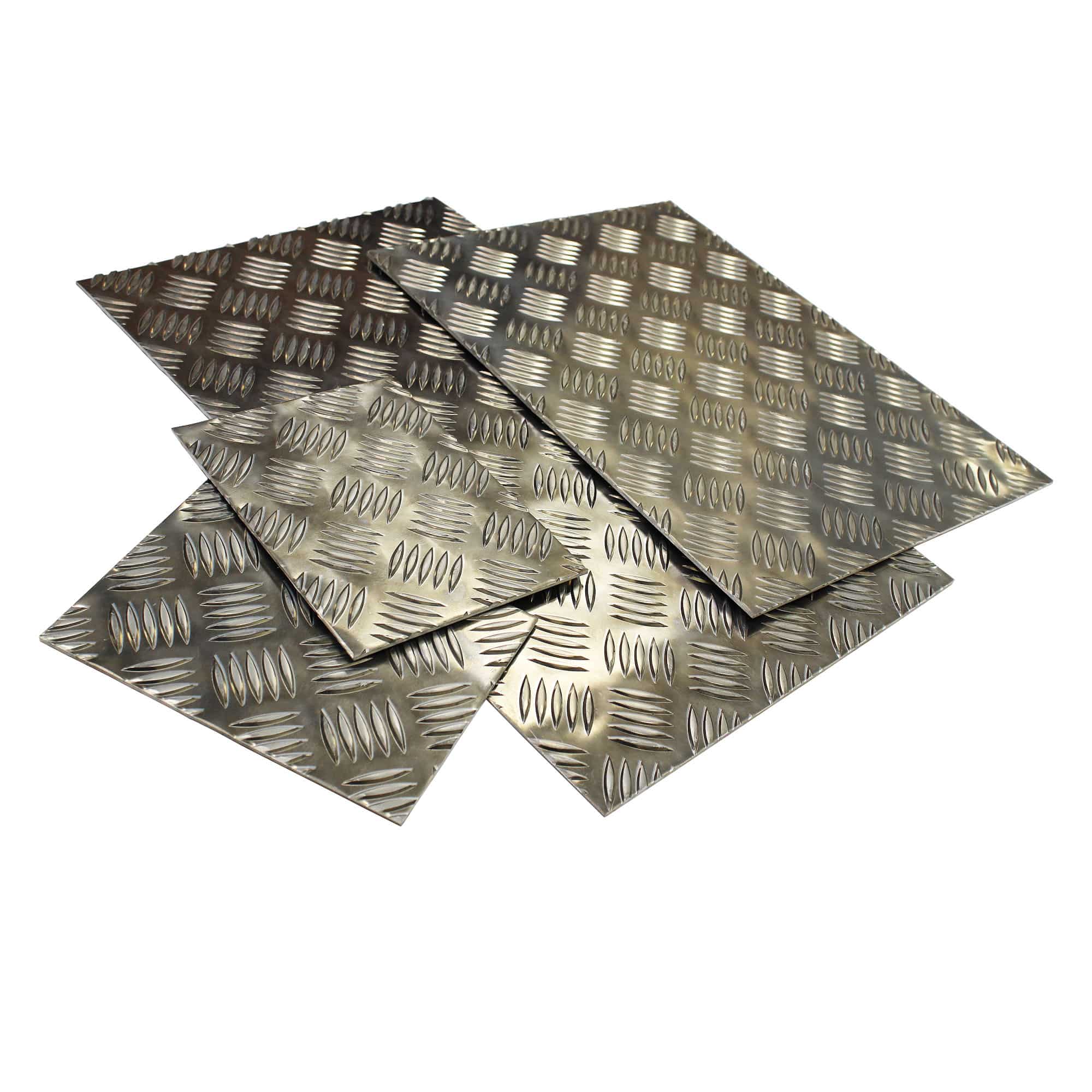

Aluminium sheet metal is a versatile and cost-effective material that can be used in a variety of applications. It is lightweight, durable, corrosion resistant and has excellent thermal conductivity, making it an ideal choice for industrial and commercial projects. Aluminium sheet metal can be easily shaped to fit almost any project requirement, offering excellent flexibility for designers and fabricators. It is also relatively easy to work with, allowing it to be cut, formed, bent and welded into any desired shape.

We offer a wide selection of aluminium sheet metal online from trusted mills within the UK. Providing high-quality, low-priced aluminium sheet products to UK businesses and the general public, Speciality Metals is a leading aluminium metals supplier.

Aluminium sheet metal is an ideal choice for projects where strength is a priority, as its high strength-to-weight ratio makes it less likely to deform under loading or vibration. Its non-magnetic properties also make it a good choice for electrical applications. Additionally, its low cost and wide availability makes aluminium sheet metal an economical material option. With these benefits, aluminium is an ideal material for many industrial and commercial projects.

These aluminium sheets are offered here in small sizes to suit all requirements. We also offer metal sheet in full 2 metre x 1 metre panels.

Quick product details:

Sheet metal is also available in mild steel and stainless steel.

Speciality Metals is known to be the United Kingdom’s best up-and-coming small-quantity metal company.

Furthermore we stock a vast range of plain sheet plate options that compliment our mesh range perfectly.

Over 50,000 customers of Speciality Metals are provided with fast, friendly customer service every year. We’re the place to try when you need metal of any shape and size. We’re based in Warrington, UK. We pride ourselves on our rapid turnaround and a large range of options.

Sheet metal is made by a process called rolling, which involves passing a metal ingot or slab through a pair of rollers to reduce its thickness. The rollers can be adjusted to change the thickness of the metal plate, and the process can be repeated multiple times to achieve the desired thickness. Other methods of making metal sheet include stamping, drawing and extrusion.

Here is a general overview of the process:

Among the applications of aluminium sheet metal are construction (facades, roofs, and siding), transportation (auto body panels, aircraft, and marine components), packaging (cans and containers), and industrial applications (pressure vessels, tanks, and machinery). It is commonly used for signs, displays, and electrical components. Aluminum sheet metal can also be used to make jewellery and artwork.

Due to its versatility and wide range of applications, aluminium sheet metal is a popular choice among fabricators, engineers, and architects. The possibilities are almost endless when it comes to sheet metal roofs, vehicle panels, and canopies, as well as machine parts, enclosures, furniture, and outdoor structures. Besides air conditioning equipment, ventilation systems, gutters, and downpipes, aluminium sheet metal is also preferred for many other applications.

It is necessary to use a tool or saw designed specifically for cutting aluminium when cutting sheet metal. This can include circular saws, jigsaws, band saws, plasma cutters and shears. The blades for all of these tools must be specifically designed for metal cutting, as regular blades will not work. It is important to take all safety precautions before using any sheet metal tool or saw. When cutting sheet metal, you should wear gloves and eye protection to prevent injuries and debris from flying into your eyes.

For a clean cut, sheet metal must also be properly marked. Once an area has been marked, the material should be clamped down to ensure a stable cutting surface. This will also help reduce the risk of any further injuries during cutting. Finally, it should be cut at a slow and steady pace to ensure accuracy. This will allow for more precise cuts and a better aesthetic finish.

It is relatively easy to determine the weight of sheet metal – but is crucial for construction and manufacturing. To calculate the weight of aluminum, you will need to know the volume and density of the metal. Calculating the volume is easiest when measuring the length and width in centimetres, then multiplying them together to get the area in square centimeters. From there, multiply this number by your chosen thickness to get its volume. The weight of your metal can be calculated by multiplying the volume by the density of aluminium (2.7g/cm2). For architectural projects or estimating material costs, knowing the weight of sheet metal is extremely useful!

We recently wrote a detailed blog article which provides the various calculations that you may need to accurate calculate the weight of the sheet metal required for your project.

Check out our recent article ‘Frequently Asked Questions About Aluminium Sheet Metal’ for a deeper dive into all things aluminium sheeting.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs, videos and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

If you have any further questions, feel free to contact us.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

£11.66 – £25.41 inc VAT

£13.33 – £51.66 inc VAT

£11.66 – £25.41 inc VAT

£13.33 – £51.66 inc VAT

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options