- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » What Is Aluminium Sheeting?

Among metals, aluminium sheeting stands out for its lightweight, strong composition, carving a niche across a wide range of industries. Whether it’s the sleek skin of aircraft, the durable bodies of automobiles, or elegant facades of modern architecture, aluminum is ubiquitous. First isolated in the early 19th century, this remarkable metal has undergone a fascinating evolution. Due to advancements in extraction and processing techniques, aluminium has become one of the most widely used materials in industrial applications.

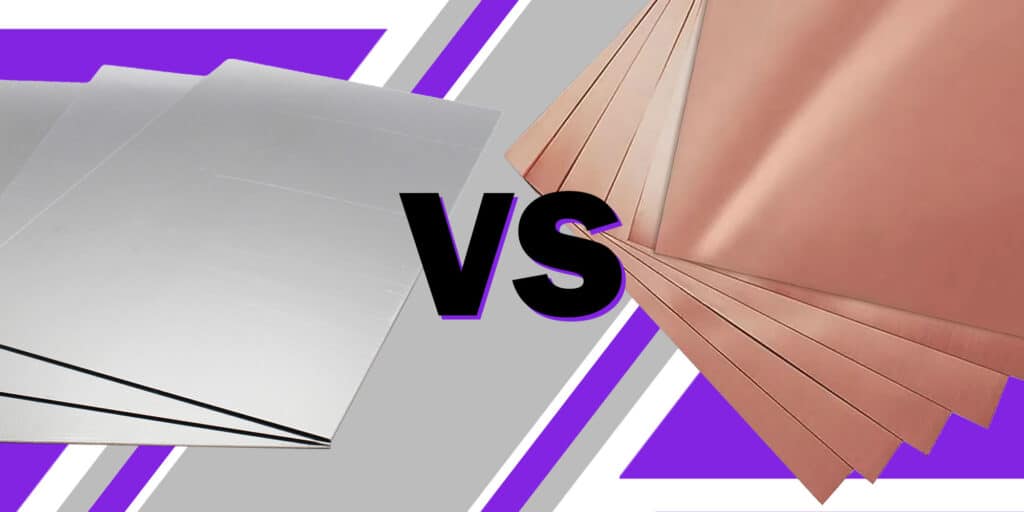

With this comprehensive exploration of aluminium sheeting, we’ll learn about its properties, applications, and how to choose the right type. A fundamental understanding of aluminium sheeting, including its composition, manufacturing process, and grades, is crucial for both industry professionals and enthusiasts. The purpose of this article is not only to highlight the unique advantages of aluminum over other metal sheetings, such as steel or copper, but also to guide you through the nuances that make aluminium a preferred choice.

Let’s go…

Here are the many advantages of aluminium:

Aluminium sheeting is incredibly versatile due to its mechanical properties, such as strength, ductility, and malleability. Aluminium can be as strong as steel depending on its alloying elements and treatment processes, yet it retains its lightness. Due to its ductility, which allows it to be stretched into a wire, and malleability, which allows it to be bent or shaped, it is suitable for use in complex designs.

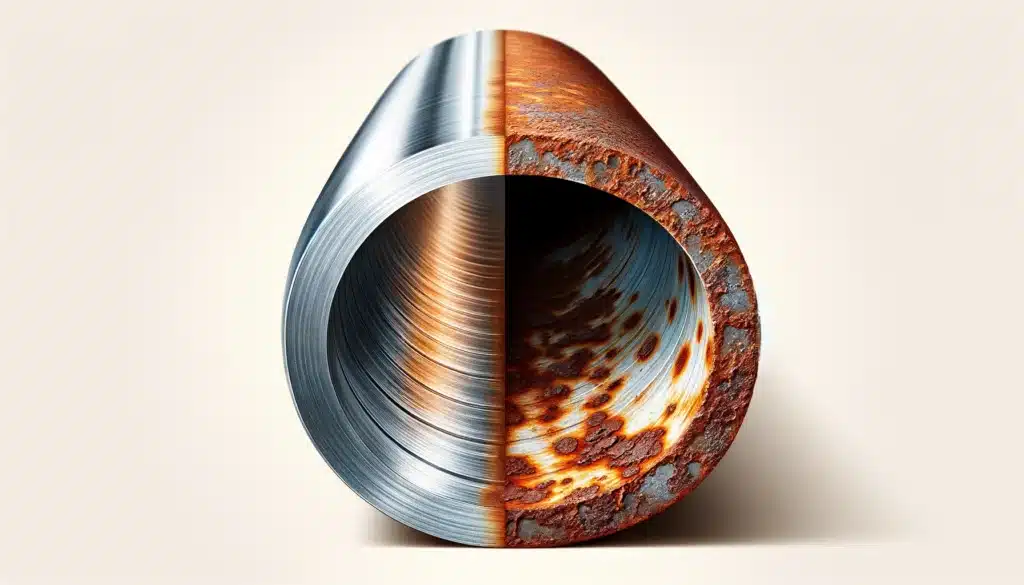

Aluminium forms a protective oxide layer when exposed to air, making it extremely corrosion resistant. Especially in harsh environments, this property prevents the metal from deteriorating rapidly. In addition to being non-toxic, it is also suitable for food packaging and kitchen utensils.

In the alloying process, magnesium, silicon, and copper are added to aluminium sheeting to enhance specific properties. Magnesium increases its strength and corrosion resistance, while silicon improves its casting abilities. Through alloying, aluminium sheeting can be tailored to meet the demands of diverse applications, such as high-strength architectural structures and flexible packaging.

Aluminium sheeting is a popular material choice across various industries due to its unique advantages, but it also has some limitations. In order to make informed decisions regarding its use in different projects, it is important to understand these factors.

Benefits of Aluminium Sheeting:

Lightweight: In industries such as automotive and aerospace where weight reduction is crucial, aluminum’s low density makes it about one-third the weight of steel.

Corrosion Resistance: When aluminium is exposed to air, it forms an oxide layer that provides excellent corrosion resistance. It is therefore ideal for outdoor applications, such as architectural cladding and marine environments.

Malleability and Formability: Due to its malleability, aluminum can be rolled into thin sheets or shaped into various shapes without breaking, which is necessary for complex applications.

Conductivity: Suitable for electrical and thermal applications, it conducts electricity and heat well.

Recyclability: Aluminium is 100% recyclable without losing quality, making it a sustainable material. Only 5% of the energy required to produce the original metal is used in its recycling process.

Despite the fact that aluminium has many benefits, there are also a few disadvantages of aluminium such as:

Strength Limitations: Although certain aluminium alloys are strong, they are generally weaker than steel. It may be necessary to choose specific high-strength alloys or consider alternative materials for applications requiring higher strength.

Cost: Particularly specialized alloys and finishes can make aluminium more expensive than other metals like steel.

Machinability: Due to its softness and the risk of adhering to cutting tools, aluminum can be more challenging to machine than other metals.

Thermal Expansion: Aluminium expands more than steel in response to temperature changes, which can be a consideration in environments with wide temperature variations.

Chemical Sensitivity: Aluminium can be corroded by certain chemicals, so it is important to understand the conditions in which the material will be used.

The unique properties of aluminium sheeting have enabled it to play a significant role in a variety of industries. Its lightweight yet strong nature makes it essential in aerospace. Most aircraft bodies are made from aluminum sheets, as they provide strength without adding excessive weight, crucial for fuel efficiency and flight dynamics. In the Boeing 747, for example, aluminium sheeting forms a significant part of its structure, making it both lightweight and durable.

Fuel efficiency and reduced emissions are driving the shift to aluminium sheeting in the automotive sector. Aluminium sheets are extensively used in car bodies and frames by manufacturers like Audi and Tesla. In addition to reducing vehicle weight, this also improves performance and battery range.

Aluminium is valued by the construction industry for its durability and corrosion resistance. It’s widely used in roofing, wall cladding, and window frames. Aluminum sheeting is also excellent for insulation because of its reflective properties. Aluminum is used in the Empire State Building’s interior structures, highlighting its long-term durability.

The excellent heat dissipation properties of aluminium sheeting make it a popular choice for electronics in consumer goods. Food and beverages are also preserved by its non-toxic nature and impermeability.

In emerging industries like renewable energy, aluminium sheeting holds immense potential. Due to its high strength-to-weight ratio and resistance to weathering, it is increasingly used in solar panel frames and wind turbines.

Selecting the appropriate aluminium sheeting for a project involves understanding the specific requirements of the application. Consider the following:

Another form of aluminium we specialise in is aluminium checker sheets, also known as aluminium chequer. This is essentially 1050 grade aluminium sheets with a distinctive 5 Bar raised tread that allows a non-slip surface.

Aluminium checker can be used in a variety of ways as it has lots of advantages for example it can bring safety and protection to any workplace or an interesting look to a room with its attractive appearance. Some uses of aluminium checker are:

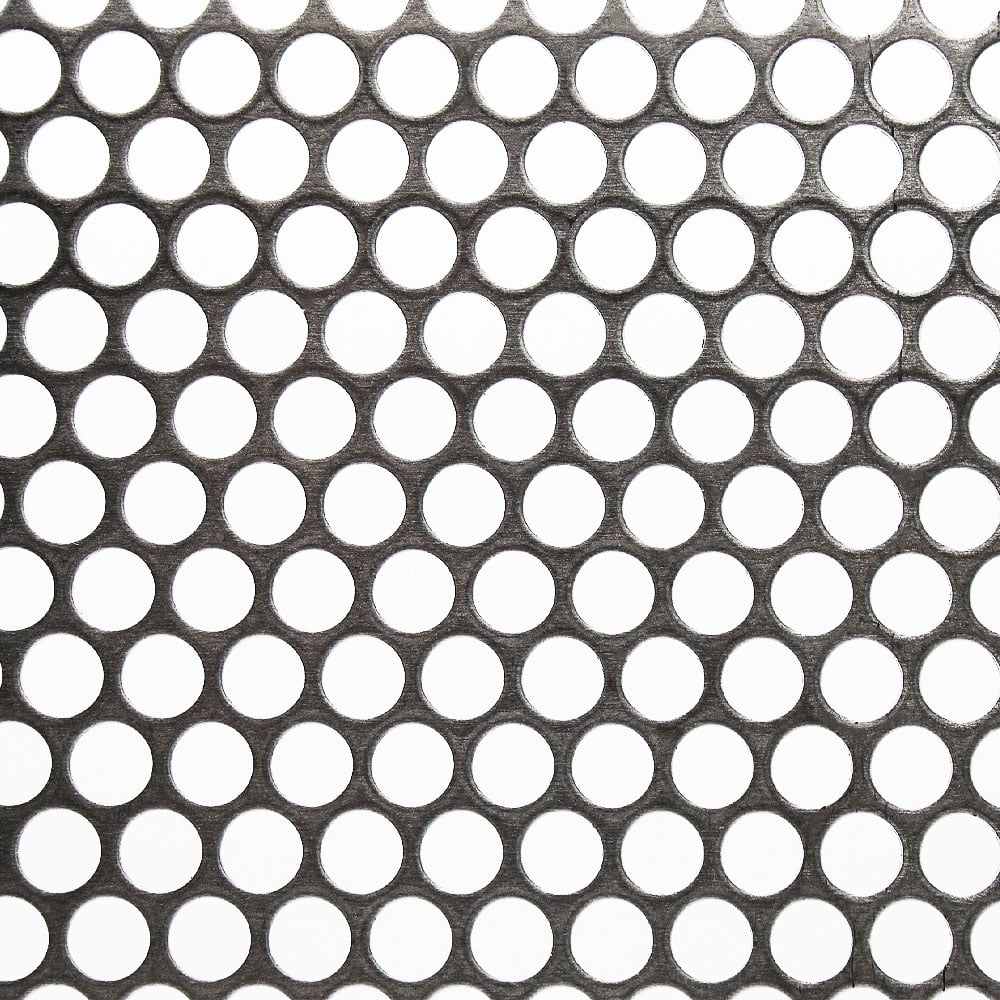

Perforated sheet metal is also another form of aluminium that we offer.

Perforated aluminium plate is 1050 grade aluminium metal sheet that has had holes punched out by an industrial machine. These punctured holes can come in range of different shapes and sizes. We offer perforated mesh holes in round and square holes in aluminium although we also supply hexagon shape perforated mesh but in different metals.

Additionally, aluminium perforated mesh also has lots of uses that are beneficial to many industries and even DIY projects. Because of the punched holes, this feature makes perforated mesh great for using in a range of applications.

Perforated mesh made from aluminium also brings many benefits to any project as it has a lot of features. Some features are:

Wind resistance – because of the holes in the perforated mesh, this allows air to pass through however this also causes wind resistance as the air flow is mostly limited.

Great ventilation – as perforated mesh allows air to pass through, this also means that it supports a great ventilation system and are commonly used as grills on vehicles or on the exterior of buildings.

Strong structure – aluminium is a strong, durable metal. It also has many assets such as it’s resistant to corrosion, heat and chemicals and it’s weatherproof. This means it’s suitable for outdoor projects and it will last a long time even in extreme environments.

Noise reduction – perforated mesh has great sound insulation, you can easily install it on a wall or a ceiling to reduce sound from coming through. Like aluminium chequer, it’s also great for wall cladding.

Attractive appearance – there are many types of perforated mesh all with a different appearance. It’s often used as interior and exterior architecture as it can have an appealing look.

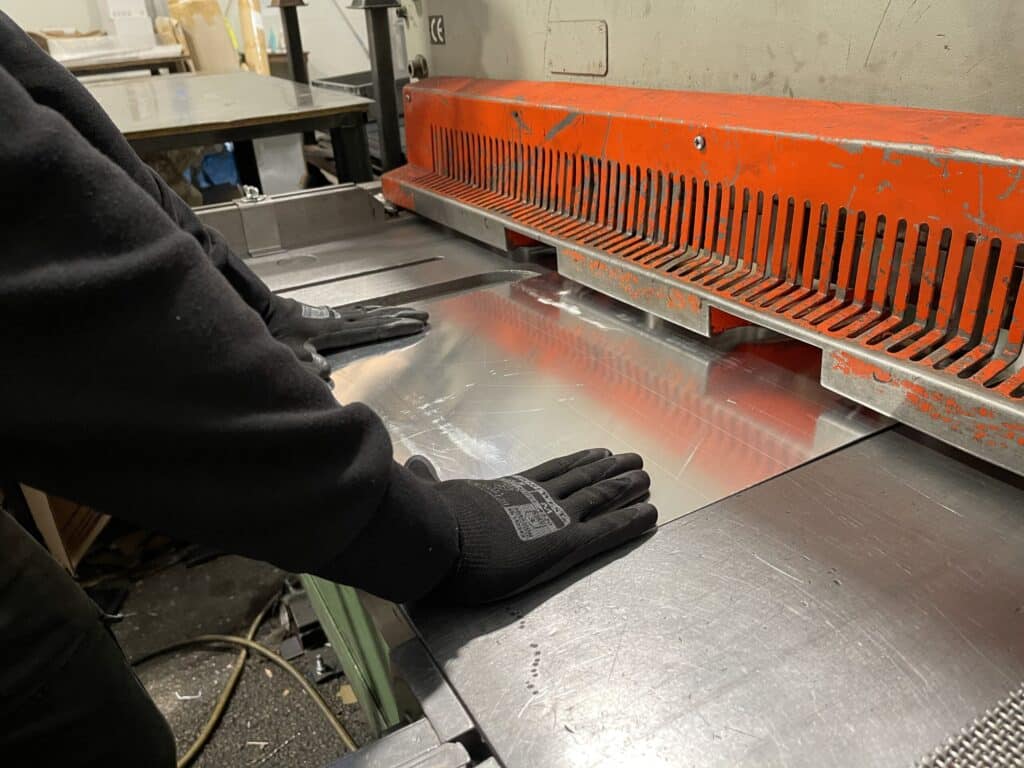

All of our aluminium sheeting plates, including aluminium chequer and perforated, come in 500mm x 1000mm size panels. We then guillotine them down to smaller size sheets to suit all requirements.

We cut down our sheet metal using our ultra-powerful industrial guillotine and then we de-burr the edges where possible.

The large panels are sent on pallets before slitting them down to 500mm x 1000mm or smaller on our industrial guillotine.

Our cutting service protocols are to be rapid, fuss-free and to accommodate to any request no matter how big or small.

Our industrial machine allows us to cut aluminium sheeting down to any size you require and we have no minimum order requirement so if you are looking to buy metal in small amounts then we are the place for you.

Aluminium sheeting is versatile and useful across a wide range of industries. From aerospace and automotive applications to construction and DIY projects, its lightweight nature, strength, and corrosion resistance make it a popular choice. As technology and alloy development advance, aluminium sheeting offers even more possibilities for innovation.

As a professional supplier of high-quality aluminum sheeting, Speciality Metals caters to a wide range of project needs. Whether you’re working on a complex industrial task or a creative endeavor, our range is designed to meet your specifications with the utmost precision and quality. Take advantage of our expertise to find the ideal aluminium sheeting solution for your project by exploring our selection.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options