- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » How to Install and Maintain Aluminium T Section: Tips and Tricks

Aluminium T section is a popular and widely used profile for a variety of industrial, architectural, and decorative applications.

It provides exceptional strength, corrosion resistance, and aesthetic appeal as a durable and lightweight material.

It’s important, however, to follow proper installation and maintenance practices to ensure the best performance and longevity. Here are some tips and tricks for handling, cutting, joining, and protecting aluminium T sections.

Let’s go…

There are some basic safety precautions you need to follow when handling aluminium T section profiles. Ensure that you wear gloves, protective eyewear, and appropriate clothing so that you do not get injured by sharp edges or debris. It would be a good idea to store the profiles on a flat surface or a specialised rack so that they won’t stack on top of each other. It is recommended that you protect the profiles from direct sunlight, moisture, and extreme temperatures as these can negatively affect the quality and performance of the profiles.

In order to avoid damage and achieve accurate results when cutting and machining aluminium T section profiles, some special techniques and tools must be used. During the cutting process, it is recommended that you use a fine-toothed saw and lubricant in order to reduce friction and heat.

In order to avoid burrs and distortions, it is recommended not to use abrasive or high-speed cutting tools. When cutting notches, angles, or curves, you will need to take extra care to prevent cracks or splits from occurring. In order to smooth the surface and remove sharp edges, you can use a deburring tool or sandpaper if necessary.

A T-section aluminum profile can be joined or fixed in a variety of ways, depending on the application and the load requirements. It is common to weld, screw, bolt, rivet, or adhere materials together using a variety of methods. As with all methods, each has its advantages and limitations, and may require different tools and expertise in order to be effective. In order to prevent stress concentration and deformation, it is important to ensure that the joints and fixings are properly aligned, secured, and supported. You should use fasteners and filler materials that are compatible with aluminum and that can withstand the loads and conditions that you expect them to withstand.

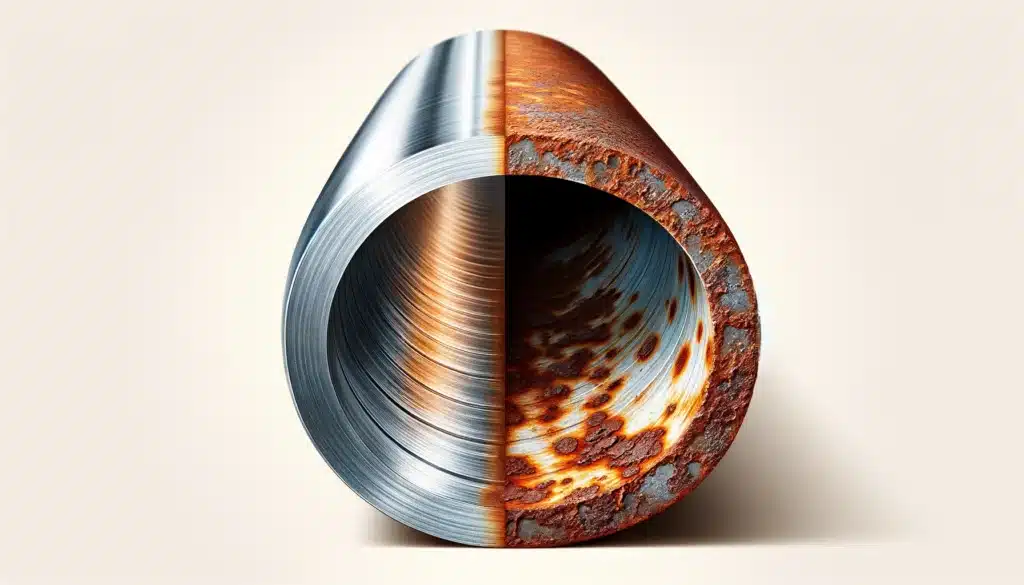

There is a risk of corrosion and staining of aluminium T section profiles if they are exposed to harsh environments or surfaces that are contaminated. In order to protect them from damage, it’s important to apply a coating or sealant that will protect them from damage and preserve their appearance. It is possible to choose from a range of coating options, depending on the level of exposure and the desired finish, such as powder coating, anodizing, or painting, depending on the level of exposure and the desired finish. It is important to clean the profiles regularly with a non-abrasive cleaning solution and a soft cloth in order to remove dirt, dust, or grime from them. The surface or the coating should not be cleaned with harsh or acidic cleaners that could damage the surface or the coating.

In order to ensure the optimal performance and longevity of aluminium T section profiles, it is vital to inspect and maintain them on a regular basis. It is very important that you keep an eye out for any signs of damage, deformation, or corrosion, and take corrective measures as soon as possible. The profiles should be cleaned and re-coated if necessary, and any moving parts and joints should be lubricated in order to ensure smooth operation in the future. It is important to monitor the load and stress levels and adjust the fixings and supports if they need to be adjusted at any time. In order to properly care for the equipment over the long term, it is essential to keep records of maintenance and inspection activities that have taken place.

There are many advantages to using aluminum T section profiles for a wide range of applications, but proper installation and maintenance are essential to maximizing their potential. If you follow some basic tips and tricks, you will be able to handle, cut, join, and protect your profiles with confidence, and you will achieve optimal performance and longevity from them.

You can enjoy the many benefits that aluminium T section profiles can provide you with for many years to come if you have the right knowledge and care for them.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options