- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Advantages of Using Galvanised Steel Sheet Metal in HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems are a crucial part of many homes and businesses. Even in the UK where the weather is more clement.

We find that one the the most common uses for our galvanised steel sheet metals is in the repair and maintenance of HVAC systems. Specifically in the ductwork.

This blog will cover the reasons why galvanised steel is so good for this purpose, and the options that we have available.

Let’s get into it….

First things first. Let’s define the term.

HVAC stands for Heating, Ventilation, and Air Conditioning.

A HVAC system is a type of mechanical system that is used to provide heating, cooling, and ventilation to buildings and other indoor spaces.

These systems are typically made up of several components, including a furnace or boiler, an air conditioner or heat pump, ductwork, vents, and thermostats or other controls. These components work symbiotically to maintain a comfortable temperature and healthy air quality in a building.

During cold weather, the heating component of the HVAC system heats the air, which is then circulated through ductwork and vents to different parts of the building. During warm weather, the cooling component of the HVAC system cools the air, which is also circulated through the ductwork and vents. The ventilation component of the HVAC system is responsible for exchanging indoor air with fresh outdoor air. This helps to remove stale air, pollutants, and moisture from the indoor environment, which can improve indoor air quality and promote the health and well-being of building occupants.

HVAC systems are widely used in the UK. In fact the US, Japan, Germany and the UK are believed to have the highest number of HVAC systems per capita.

Galvanised steel sheet metal is used in a variety of ways in HVAC systems, from ductwork to air vents and other components. Here are some of the key ways that galvanized steel sheet metal is used in HVAC systems:

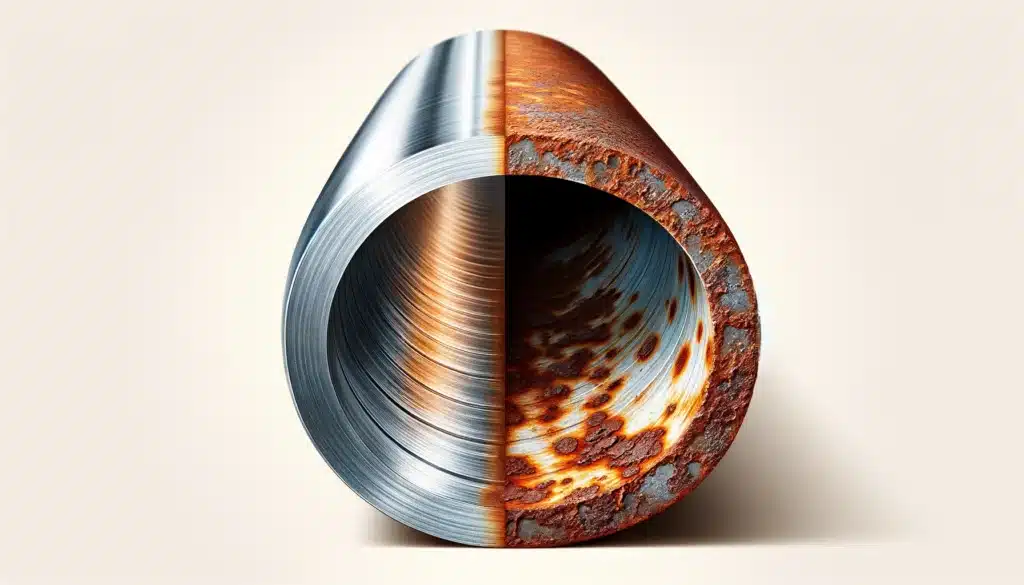

One of the main advantages of using galvanised steel sheet metal in an HVAC system is its durability and longevity. Galvanisation is a process that coats the steel with zinc, which makes it highly resistant to corrosion and rusting. This means that any air ducts made from galvanised steel will last much longer than those made from other materials like aluminium or copper. In addition, galvanised steel is also very strong, which means it can withstand temperature fluctuations without warping or cracking.

Sheet metal is a common material used in the fabrication of ductwork for HVAC systems. Here’s a general overview of how sheet metal is used in HVAC ductwork:

Finally, using galvanised steel sheet metal in your HVAC system can also help you save money in the long run due to its durability and longevity mentioned above. Because the material will last much longer than other types of sheet metals, you won’t have to replace your air ducts as often as you would if they were made from another material like aluminium or copper. Additionally, because galvanised steel is relatively inexpensive compared to other metals used in HVAC systems, you may be able to save even more money on installation costs by using this material instead of more expensive options like stainless steel or brass alloys.

When it comes time to replace or upgrade your heating and cooling system, consider using galvanised steel sheet metal for your air ducts instead of other materials like aluminium or copper. This type of metal is extremely durable and long-lasting due to its protective coating of zinc which prevents corrosion and rusting over time. Plus, it’s lightweight yet strong enough to handle extreme temperatures without warping or cracking—which saves you money on installation costs in the long run too! So if you want a reliable and cost-effective solution for your HVAC system needs, look no further than galvanised steel sheet metal!

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options