- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

£19.49 – £35.99 inc VAT

This website is secured:

£ MULTIBUY SAVINGS – Order 3 For 10% Off

✔ Specialists In Rapid Shipments Of Any Size

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

@ ☏ Bespoke Cuts & Larger Sheets Available

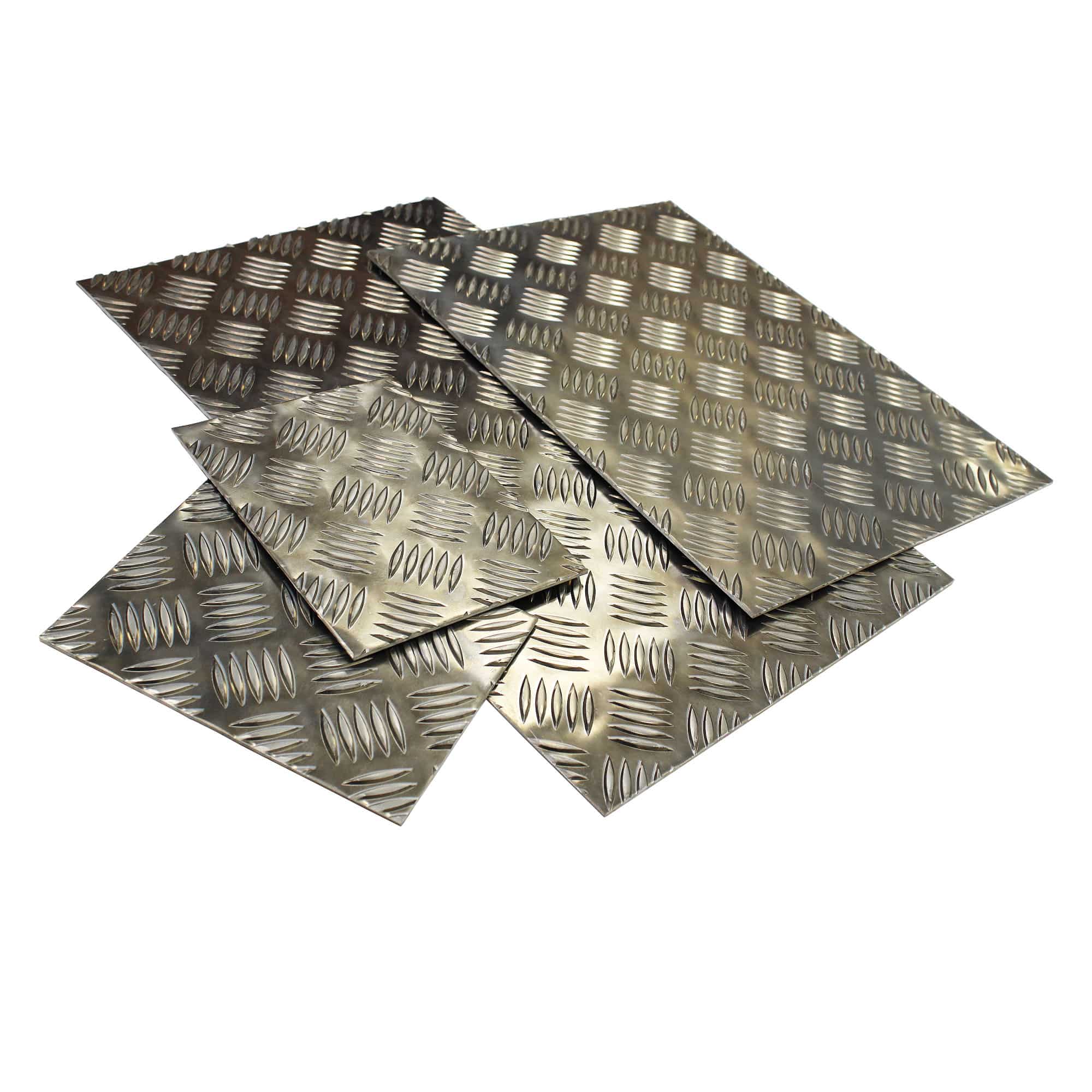

Looking for a galvanised metal sheet that is built to last? Look no further than Speciality Metals! Our 1.5mm thick steel plates are zinc coated for added durability, making them corrosion-resistant and of top quality. Whether you’re looking for a versatile metal sheet that can be used in various applications, or need a specific size, we have the perfect solution for you. As a UK supplier, we take pride in providing long-lasting, quality products that meet the highest of standards. So why wait? Speciality Metals can make for you and your projects today!

We offer a wide selection of galvanised sheet metal online from trusted mills within the UK. Providing high-quality, low-priced galvanised sheet products to UK businesses and the general public, Speciality Metals is a leading galvanised metal supplier.

Speciality Metals offers top-quality 1.5mm thick galvanised metal sheet steel plates in various sizes to suit your project needs. The zinc-coated metal sheet ensures excellent corrosion resistance and long-lasting durability. Being versatile, it is ideal for many applications, and its premium quality promises an unyielding performance over time. Galvanised metal sheet steel plates are a cost-effective and practical solution that will serve your needs for many years. Choose Speciality Metals for reliable supply of zinc-coated, corrosion-resistant galvanised metal sheet steel plates.

We are the best suppliers for your needs because:

Quick product details:

Sheet metal is also available in aluminium and stainless steel.

Yes, you can use 1.5mm thick galvanised steel plates for manufacturing certain automotive parts. The galvanised coating on the steel provides excellent corrosion resistance, making it suitable for components that require protection against environmental factors, such as moisture, road salts and other elements encountered in automotive applications.

Automotive body panels, such as fenders, hoods and doors can be fabricated from galvanised steel plates to enhance their resistance to rust and extend their lifespan. Additionally, structural components like brackets, chassis parts and undercarriages can benefit from the durability and strength of galvanised steel. However, it’s important to note that not all automotive parts may be suitable for galvanised steel. Specific applications, such as those involving high-temperature environments or parts that require specific surface coatings for additional performance characteristics, may necessitate alternative materials. When considering galvanised steel for automotive manufacturing, it is essential to ensure that the chosen grade and thickness of the galvanised steel meet the required mechanical and safety specifications for the intended parts. Adherence to automotive industry standards and regulations is crucial to ensure the quality and performance of the manufactured components.

No, using galvanised steel plates for direct food-related applications is not recommended. While the zinc coating on galvanised steel provides excellent corrosion resistance, it is not considered food-safe. The zinc coating can potentially leach into food or food processing surfaces, which may pose health risks if ingested. In food-related applications, it is essential to use materials that are specifically designed and approved for contact with food. Stainless steel and food-grade plastics are commonly used in the food industry due to their non-reactive and food-safe properties. These materials meet strict safety and hygiene standards, ensuring that they do not introduce any harmful substances into the food. For food processing equipment, food storage containers, and other food-related applications, it is best to choose materials that comply with food safety regulations and industry standards. This will help ensure the safety and integrity of the food products and maintain compliance with food handling and processing guidelines.

Galvanised steel plates require minimal maintenance to preserve their corrosion resistance and performance over time. Regular cleaning with mild detergent and water is typically sufficient to remove dirt and debris that may accumulate on the surface. Avoid using abrasive cleaners or harsh chemicals that could damage the zinc coating. If the galvanised steel plates develop small scratches or areas where the zinc coating is compromised, applying touch-up zinc-rich paint can provide added protection and prevent localized corrosion. The zinc-rich paint acts as a sacrificial layer, further safeguarding the underlying steel. Periodic inspections of the galvanised steel plates are recommended, especially in aggressive environments or high-exposure areas. Check for signs of corrosion or wear, and address any issues promptly to prevent further degradation. In areas with heavy industrial pollution, saltwater exposure, or severe weather conditions, more frequent inspections and maintenance may be necessary. Regular maintenance ensures that the galvanised steel plates continue to offer optimal corrosion resistance and remain in good condition for their intended lifespan.

While galvanised steel plates offer good corrosion resistance, their suitability for roofing in areas with extreme weather conditions depends on several factors. Galvanised steel can be used for roofing in various weather conditions due to its durability and resistance to rust. However, in areas prone to extreme weather events such as frequent hurricanes, cyclones, heavy snow loads or severe hailstorms, additional considerations are necessary. For roofing in areas with extreme weather conditions, it is essential to adhere to local building codes and engineering requirements. Roof designs may need to be reinforced to withstand high winds or heavy snow accumulation. Roofing professionals may recommend specific fastening methods and support structures to ensure the roof’s stability and integrity under extreme conditions. Using thicker gauge galvanised steel plates or considering alternative materials, such as steel alloys or impact-resistant coatings, can enhance the roofing system’s ability to withstand severe weather impacts. Proper installation, including professional sealants and flashing details, is critical to preventing water intrusion and maintaining the roof’s weather resistance. Regular inspections and maintenance should be performed to identify and address any potential issues early on.

Consulting with experienced roofing contractors and engineers familiar with the local climate and weather patterns can help determine the most suitable roofing materials and design to ensure the roof’s resilience in extreme weather conditions.

Check out our recent article ‘Galvanised Steel vs. Aluminium – The Pros and Cons‘ for a deeper dive into all things galvanised sheet metal.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

£13.99 – £30.49 inc VAT

£17.99 – £54.99 inc VAT

£13.99 – £30.49 inc VAT

£17.99 – £54.99 inc VAT

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options