- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » What Is the Melting Point of Aluminium? A Comprehensive Guide for Every Grade

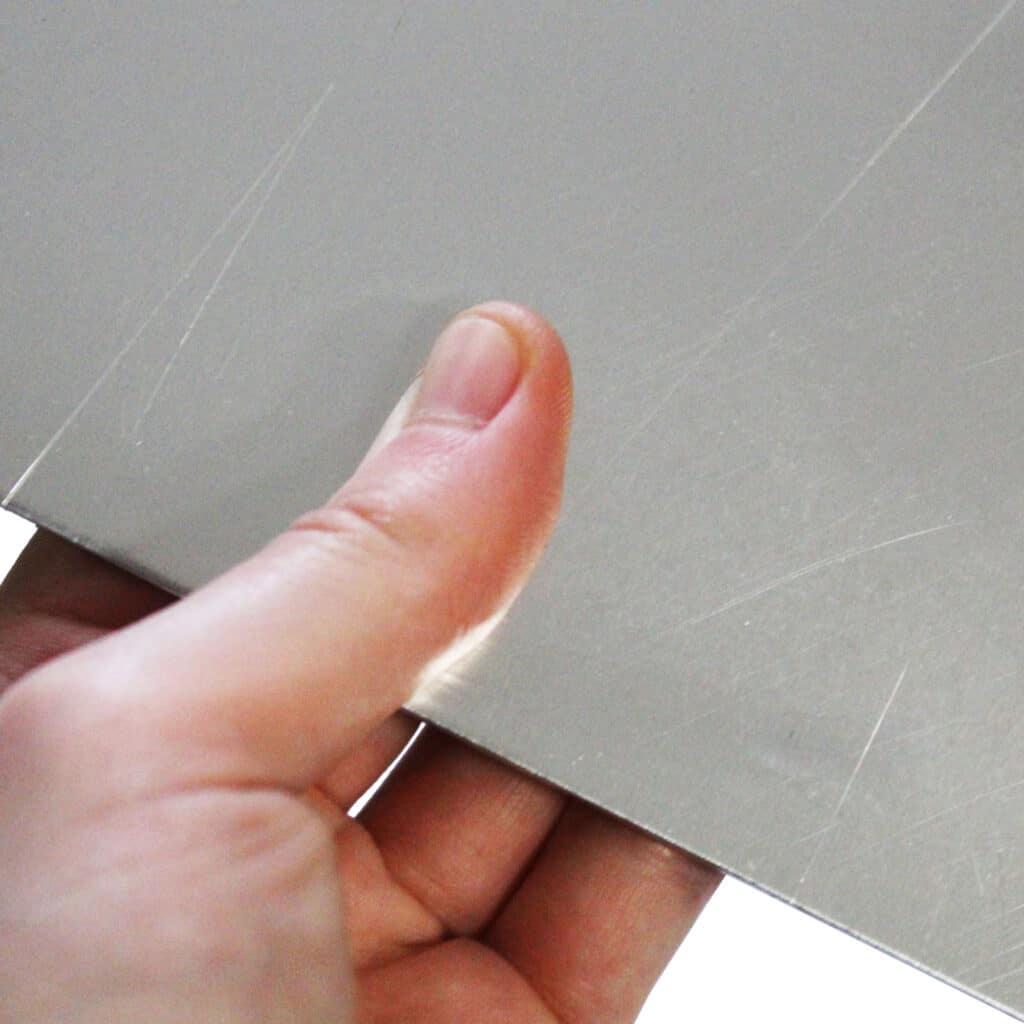

Aluminium is one of the most versatile and widely used metals in the world, valued for its lightweight properties, corrosion resistance, and excellent thermal conductivity. Whether you’re a DIY enthusiast working with aluminium sheet metal or a fabricator using aluminium tubes for industrial applications, understanding its thermal properties—especially its melting point—is essential.

The melting point of aluminium, typically around 660°C (1220°F), makes it suitable for a broad range of applications, from automotive components to aerospace structures. However, this value can vary depending on the alloy and its specific composition. Different grades of aluminium, like 1050, 5083, or 6061, may have slightly differing melting behaviours due to the addition of other metals such as magnesium, silicon, or copper.

In this guide, we’ll dive into the details of aluminium’s melting point, how alloying affects it, and why understanding these thermal properties is critical for various machining, welding, and manufacturing processes.

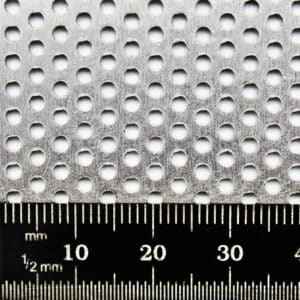

Speciality Metals provides a range of high-quality aluminium products—including round tubes, flat bars, sheet metal, T sections, U channels, and woven mesh—designed to meet your specific project needs. Let’s explore what makes aluminium such an invaluable material, starting with its melting point.

Pure aluminium has a melting point of approximately 660°C (1220°F), which is relatively low compared to other metals like steel (melting point ~1370°C). This characteristic makes aluminium easier to melt and reshape, making it ideal for casting, forging, and extrusion processes.

At its melting point, aluminium transitions from a solid to a liquid, but this process can vary slightly based on the presence of alloying elements.

Speciality Metals’ aluminium products, such as flat bars or sheet metal, maintain high performance in applications requiring elevated temperatures, making them ideal for a range of industries.

While pure aluminium melts at 660°C, the addition of other metals creates aluminium alloys, which can slightly lower or raise the melting point. Let’s look at some common aluminium grades and how their melting points are influenced.

1050 Aluminium (Pure Aluminium):

5083 Aluminium (Marine Grade):

6061 Aluminium (Structural Grade):

The melting point of aluminium plays a significant role in determining its application in various industries. Let’s explore some practical scenarios where this property is crucial.

Aluminium’s thermal conductivity, combined with its relatively low melting point, makes it ideal for heat exchangers in HVAC systems, radiators, and industrial cooling units.

In aerospace engineering, materials are often exposed to extreme temperature fluctuations. Aluminium alloys like 6061 are frequently used for structural components because of their high strength-to-weight ratio and ability to withstand elevated temperatures.

The automotive industry values aluminium for engine components, heat shields, and body panels. Its low melting point allows for easier casting and shaping while maintaining strength and corrosion resistance.

For metalworkers, the melting point dictates which processes can be used. Aluminium’s relatively low melting range allows for efficient MIG and TIG welding, making it a popular choice for custom fabrication.

Aluminium’s low melting point makes it more challenging to weld than steel. Proper preparation, the right filler material, and techniques like TIG or MIG welding are essential for success.

When machining or working with aluminium, overheating can cause distortion or loss of strength. Always use cutting fluids and appropriate speeds.

Heat treatment can enhance the strength or ductility of aluminium alloys. Understanding the melting range ensures you don’t overheat and compromise the material’s integrity.

This slightly thicker sheet balances flexibility and strength, offering a durable yet workable option for delicate applications.

Uses: Signage, reflective surfaces, and interior trim panels.

Projects: Perfect for small-scale repairs, custom labels, and enhancing the look of decorative fixtures.

Providing a good balance between workability and resilience, 1.2mm aluminium sheet is versatile for structural and decorative projects.

Uses: HVAC panels, small cladding jobs, and machine guards.

Projects: Great for creating signage, lightweight furniture accents, and custom fittings.

A versatile option for both decorative and functional projects, 2mm aluminium sheet combines strength with adaptability.

Uses: Roofing panels, medium-duty brackets, and framing components.

Projects: Popular for outdoor projects like planters, toolboxes, and decorative architectural features.

With its excellent strength and rigidity, 3mm aluminium sheet is well-suited for structural projects and heavy-duty applications.

Uses: Skirting boards, tool mounts, and heavy-duty decorative panels.

Projects: Ideal for industrial worktops, outdoor storage units, and reinforced cladding.

Designed for projects that demand durability, 5mm aluminium sheet is highly resilient while retaining workability.

Uses: Frameworks, marine components, and industrial panels.

Projects: Great for boat repairs, trailer fabrication, and making heavy-duty brackets or guards.

This ultra-thin aluminium sheet is ideal for applications requiring flexibility and precision, making it a go-to material for lightweight designs.

Uses: Model-making, decorative panels, and heat shielding.

Projects: Great for crafts, intricate DIY designs, and creating lightweight coverings for appliances or gadgets.

Thin but sturdy, 1mm aluminium sheet is an excellent choice for projects that require durability without adding unnecessary weight.

Uses: Kitchen splashbacks, control panel covers, and lightweight enclosures.

Projects: Ideal for making custom brackets, vehicle interior trim, and bespoke architectural features.

This medium-thickness aluminium sheet offers enhanced strength while remaining easy to work with, making it ideal for everyday projects.

Uses: Protective covers, automotive panels, and small structural components.

Projects: Perfect for repairing vehicle bodywork, making custom fixtures, and crafting industrial prototypes.

Slightly thicker for added durability, this sheet works well in projects requiring more robust solutions without compromising on weight.

Uses: Medium-duty enclosures, furniture bases, and vehicle modifications.

Projects: Great for shelving supports, caravan repairs, and sturdy outdoor furniture.

4mm aluminium sheet provides a higher level of structural integrity, making it perfect for more demanding applications.

Uses: Machine components, load-bearing plates, and custom vehicle parts.

Projects: Frequently used for heavy-duty shelving, skid plates, and structural reinforcements.

The thickest aluminium sheet in our range, 6mm is ideal for heavy-duty structural applications requiring maximum strength and stability.

Uses: Baseplates, industrial fixtures, and load-bearing elements.

Projects: Perfect for construction components, machinery bases, and creating long-lasting outdoor fixtures.

Understanding the melting point of aluminium is essential for making informed decisions about its use in various projects. Whether you’re crafting decorative panels or fabricating heat exchangers, knowing how your chosen aluminium grade behaves under heat ensures optimal results.

Speciality Metals offers a range of high-quality aluminium products, including sheet metal, round tubes, flat bars, T sections, and U channels, designed to meet the needs of professionals and DIY enthusiasts alike. With our extensive range and expertise, you can find the perfect aluminium product for any application.

For expert advice on choosing the right aluminium grade or assistance with your next project, contact Speciality Metals today or explore our range online. Let’s make your aluminium project a success!

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options