- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

£18.99 – £39.99 inc VAT

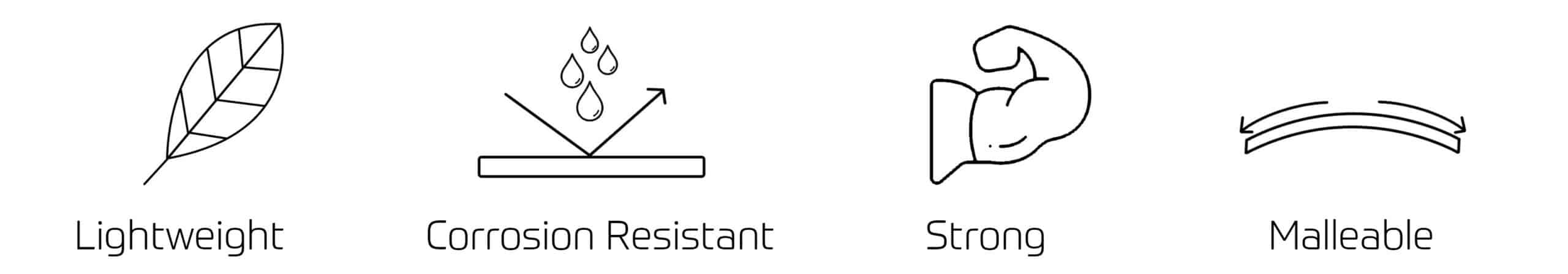

Looking for a perforated sheet that offers both durability and exceptional hygiene properties? Look no further than the 2mm Round Aluminium Perforated Sheet by Speciality Metals! This sheet boasts a 3.5mm pitch and 1mm thickness, making it the perfect solution for a wide range of applications. Additionally, this sheet is known for its high resistance to corrosion and ability to conduct both thermal and electrical energy. And, at just one millimeter thick, this sheet is lightweight and malleable – making it easy to work with and perfect for projects where flexibility is key. Best of all? This sheet is completely odorless, providing an added layer of convenience for those seeking to maintain a clean, fresh environment.

Top quality aluminium perforated sheet supplied straight from Warrington, UK.

Aluminium Perforated Sheet, 2mm round, from Speciality Metals is an excellent material for industries requiring exceptional hygiene properties. Sheets manufactured from Aluminum have a 3.5mm pitch and a 1mm thickness, ensuring long-term durability and strong performance. Aluminium Perforated Sheet is not only lightweight, but it is also electrically and thermally conductive, making it suitable for many applications. Aside from its odorless and corrosion-resistant property, the perforations in the sheet make it ideal for settings that require a high level of cleanliness. Additionally, its malleability allows for customisation to meet the specific needs of each project. As a result, Aluminium Perforated Sheet is a reliable and practical solution for diverse industries, especially those with specific requirements for materials such as cleanliness and durability.

Specifications:

We also are the exact suppliers for you because:

Furthermore we stock a vast range of plain sheet metal options that compliment our mesh range perfectly.

Aluminum perforated mesh is a lightweight, durable and versatile material created by punching or machining patterns of holes, slots or decorative shapes into aluminum sheets or panels. Renowned for its inherent corrosion resistance, aluminum mesh is especially valuable in environments where rust prevention is crucial. Its design flexibility allows for a wide array of perforation styles, catering to both functional and aesthetic needs. This makes it an ideal choice for a multitude of applications, including architectural elements like facades and decorative partitions, industrial uses such as filters and ventilation panels, acoustic solutions for sound diffusion and even agricultural screens. While it’s known for its minimal maintenance requirements, in areas with high pollutants or salt exposure, occasional cleaning might be necessary to retain its pristine condition.

Aluminum perforated mesh, with its blend of durability, aesthetics and functionality, finds application in a multitude of sectors. Here are some of its common uses:

Architectural and Decorative Applications:

Industrial and Technical Applications:

Acoustic Solutions:

Agricultural Uses:

Security and Protection:

Electronics:

Outdoor and Landscape Design:

Aluminum perforated mesh offers a combination of properties that make it particularly appealing for a wide range of applications. Here are some of the primary advantages of using this material:

Lightweight: Aluminum, as a base material, is lighter than many other metals, making it easier to handle, transport and install, which can lead to cost savings.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion, especially when anodised or coated. This makes it particularly suitable for outdoor applications or environments where resistance to rust and degradation is vital.

Durability: Despite its lightweight nature, aluminum is sturdy and can withstand various environmental conditions, ensuring longevity in numerous applications.

Aesthetic Versatility: The perforation process can be tailored to create a wide range of designs, patterns and hole sizes, allowing for both functional benefits and unique aesthetic appeal.

Energy Efficiency: In architectural applications, aluminum perforated mesh can act as a sunshade, reducing glare and heat gain within buildings, which can lead to energy savings.

Improved Ventilation and Airflow: The perforations allow for effective ventilation, making the mesh suitable for applications where airflow is essential, such as electronic enclosures or machinery guards.

Sound Attenuation: When used in acoustic applications, the mesh can help diffuse and reduce sound, contributing to noise control.

Flexibility in Fabrication: Aluminum is malleable and can be easily bent or shaped without compromising its structural integrity, allowing for more complex designs and forms.

Recyclability: Aluminum is 100% recyclable, aligning with sustainable and environmentally friendly building and design practices.

Low Maintenance: Given its corrosion resistance and durability, aluminum perforated mesh often requires minimal maintenance, especially compared to other materials that might degrade or tarnish over time.

Safety and Security: The mesh can provide barriers that are both visible and breathable, making it suitable for security applications where visibility is crucial, such as fencing or security screens.

While aluminum perforated sheets offer numerous advantages, they do come with some limitations. Here are the primary disadvantages associated with using aluminum perforated sheets:

Strength Limitations: Although aluminum is sturdy for its weight, it’s not as strong as some other metals, like steel. In applications requiring very high strength, it may not be the first choice.

Cost: High-quality aluminum can be more expensive than other materials, especially when considering the perforation process’s added costs.

Potential for Galvanic Corrosion: When aluminum comes into contact with certain other metals in the presence of an electrolyte, galvanic corrosion can occur. This requires careful planning and material pairing in multi-metal designs.

Limited Weight-bearing Capacity: Due to its lightweight nature, aluminum perforated sheets might not bear as much weight as solid sheets or sheets made from heavier metals.

Scratching and Denting: Aluminum is relatively soft, making it susceptible to scratches, dents or other surface damages, especially in rough environments or during installation.

Reaction with Concrete: Aluminum can corrode when in direct contact with wet concrete due to the alkalinity. This necessitates using barriers when the mesh is embedded or comes into direct contact with concrete.

Thermal Expansion: Aluminum has a relatively high coefficient of thermal expansion. This means it can expand and contract more with temperature changes compared to other metals, potentially leading to issues in some applications.

Wear Over Time: Even with its corrosion resistance, in extremely harsh environments, like coastal areas with salt spray, aluminum can still degrade over extended periods.

Anodizing Limitations: While anodizing can enhance the corrosion resistance of aluminum, it can alter the color or appearance. Moreover, scratches or damages to the anodized layer can expose the underlying aluminum to potential corrosion.

Welding Challenges: While aluminum can be welded, it requires specific skills and equipment compared to welding steel, making it slightly more challenging in some applications.

Surface Finish Variation: If different batches of aluminum perforated sheets are used for a large project, there could be slight variations in color or finish, especially if they are anodized.

Check out our blog discussing What is Perforated Mesh. It will prove a useful read to help you to make an informed decision on which material would work best for you.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs, videos and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options