- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Rectangular Hollow Tube Box Section: A Helpful Guide

So, we have a lot of metal products to choose from. There are so many questions about applications, lifespans, etc. Feel free to contact us if you need any help. We’re always happy to help.

To help our customers further, we’ve also started an epic project to create metal guides. Maybe this will give you an idea of what’s possible and what’s needed for every requirement.

One of the most popular products that we stock is rectangular tube. We hope that this guide can answer some of the questions to help you to decide on whether it is right for your application.

Let’s get cracking…

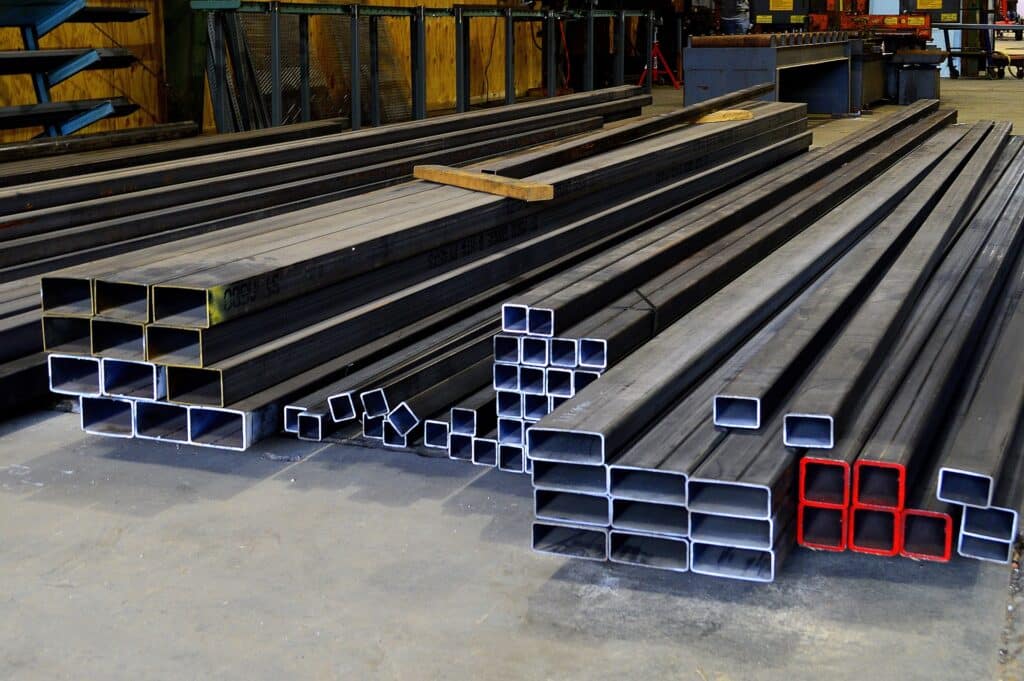

Rectangular hollow tube, also known as rectangular tubing, is a type of steel or metal tubing that has a hollowed-out rectangular cross-section. It is commonly used in construction, industrial, and manufacturing applications because of its strength and durability. The thickness of the tube’s walls can vary depending on the application and the desired level of strength and rigidity.

Rectangular hollow tube is often used in the construction of structures such as:

It is also used in the manufacturing of:

Due to its shape, rectangular hollow tube is different from round tube in terms of the strength and rigidity it can provide, as well as the way it can be cut, bent and welded.

The tube can be made of various types of steel, such as carbon steel, alloy steel, or stainless steel, and can also be made of aluminium or other non-ferrous metals.

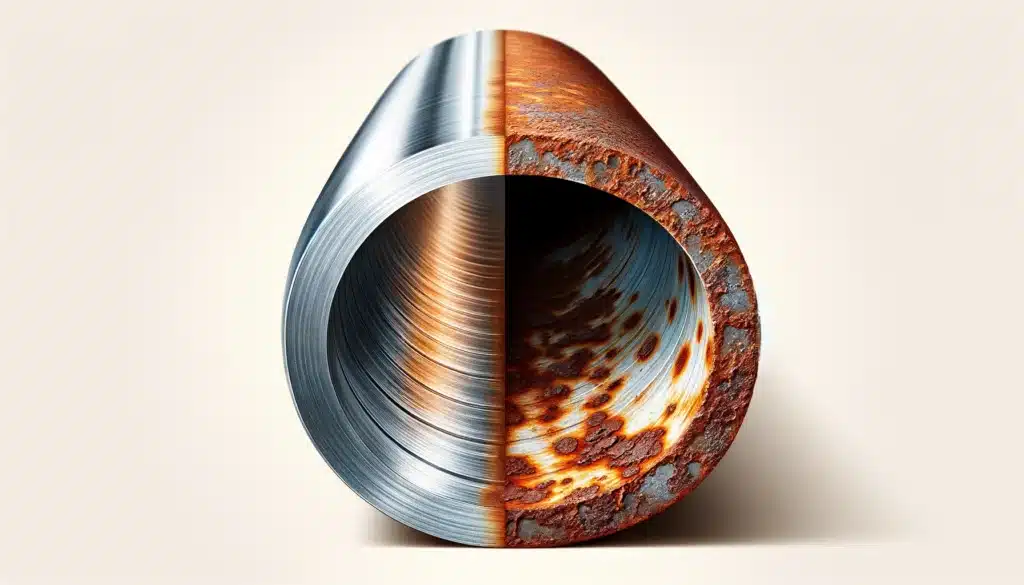

We focus on the two major metals: plain steel and stainless steel.

Yes, rectangular hollow tube can be cut, but it requires specialized tools and equipment. The most common method used to cut rectangular hollow tube is using a saw with a carbide tipped blade. Cold saws, band saws, and abrasive chop saws are also used to cut rectangular hollow tube.

It is important to note that the type of saw and blade used will depend on the thickness and type of material being cut, and the desired level of precision and finish.

If you want to make precise cuts, you can use a metal cutting band saw or a circular saw with a metal cutting blade. For a large number of cuts or for cutting large sections of rectangular hollow tube, a cold saw or abrasive chop saw would be a more efficient option.

It’s also worth noting that cutting rectangular hollow tube can be more challenging than cutting round tube because of its shape. You may need to use a specialized jig to hold the tube in place while cutting, in order to ensure a straight and accurate cut.

It’s important to use the appropriate safety equipment, such as safety glasses or goggles, when cutting metal to protect yourself from flying debris.

Also, if you have to make large number of cuts, it may be more efficient and cost-effective to have it cut by a professional metal fabrication shop that has the specialized equipment and expertise to handle the job.

Yes, rectangular hollow tube can be bent, but the process is generally more complex than bending round tubing. Bending rectangular tubing requires specialized equipment, such as a press brake or a rotary draw bender, and the process can be more challenging because the corners of the tubing may have a tendency to collapse or deform during the bending process.

The method of bending will depend on the size and thickness of the tubing, as well as the desired radius and angle of the bend. The most common methods for bending rectangular tubing are:

Compression bending: Using a die and a mandrel to bend the tube. This method is used for tubes with a small radius and for tight tolerance bends.

Rotary draw bending: Using a die and a mandrel to bend the tube. This method is used for tubes with a larger radius and for high-volume production.

It’s important to use the appropriate safety equipment, such as safety glasses or goggles, when bending metal to protect yourself from flying debris. It’s also worth noting that the tube’s material, wall thickness, and size will affect the degree of bend and the radius of the bend that can be achieved. Additionally, larger size tubes may require specialized equipment and may not be bent as easily or with as tight a radius as smaller size tubes.

Yes, mild steel rectangular hollow tube can be welded. Welding is a process that joins two pieces of metal by heating them to a high temperature and then applying pressure or a filler material. There are several welding methods that can be used to weld mild steel hollow tube, including:

It’s important to note that welding rectangular hollow tube can be more challenging than welding round tube because of its shape.

Welding rectangular tube require more skill and experience as the corners of the tubing may have a tendency to collapse or deform during the welding process. It’s also important to use the appropriate welding technique and filler material to ensure a strong and stable weld.

As always, it’s important to use the appropriate safety equipment, such as safety glasses or goggles, when welding to protect yourself from flying debris and harmful rays.

It’s also worth noting that if you have limited experience with welding or if the project is critical, it may be more efficient and cost-effective to have it welded by a professional welder or metal fabrication shop that has the specialized equipment and expertise to handle the job.

Yes, stainless steel rectangular tube can be welded. However, welding stainless steel requires a different set of procedures and equipment than welding mild steel. Stainless steel has a higher content of chromium and other alloying elements that can make it more difficult to weld. Additionally, the finished welds on stainless steel are more prone to cracking and corrosion if not done properly.

The most common methods for welding stainless steel rectangular tube are TIG welding (Gas Tungsten Arc Welding) and MIG welding (Gas Metal Arc Welding). TIG welding is a precise method that produces a high-quality weld but is a slower process. MIG welding is a faster method but can be less precise and produce a lower quality weld.

It’s important to note that welding stainless steel requires more skill and experience than welding mild steel, and the use of specialized filler materials, such as 309L, 316L or ER308, ER316L, etc, is recommended to ensure a strong and stable weld. We recommend you clean the surface of the tube before welding to remove any contaminants that could weaken the weld.

It’s also worth noting that if you have limited experience with welding stainless steel or if the project is critical, it may be more efficient and cost-effective to have it welded by a professional welder or metal fabrication shop that has the specialized equipment and expertise to handle the job.

We tend to offer these tubes in 1 metre or 2 metre lengths. It is kept simple so that we can process the orders quickly.

We stock both stainless steel and mild steel options. All ready from immediate stock for rapid dispatch.

Bespoke cuts and even bends are always possible. Please let us know if this is something that you may require and we will assist you to achieve this as best we can.

The mechanical properties of mild steel rectangular tube can vary depending on the composition and manufacturing method of the steel. However, some typical values for mild steel include:

It’s also important to note that as the term “mild steel” is not a specific material, the properties can vary with different grade and alloy.

316 stainless steel rectangular tube include a high level of strength, excellent corrosion resistance, good formability and weldability, and good cryogenic toughness. The yield strength of 316 stainless steel is typically between 185 and 215 ksi (kilopounds per square inch), and the tensile strength is typically between 515 and 690 ksi. The elongation at break of 316 stainless steel is typically 40-50%. The modulus of elasticity of 316 stainless steel is 29 x 106 psi. The density of 316 stainless steel is 0.29 lbs/in³.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options