- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Can You Use Flat Bar As A Lintel?

So you’re wanting to know more about flat bar? What it is? How to bend it? Can you use it as a lintel? If any of these questions apply to you then you’ve come to the right place.

We hope our expert information will answer all your questions on flat bar.

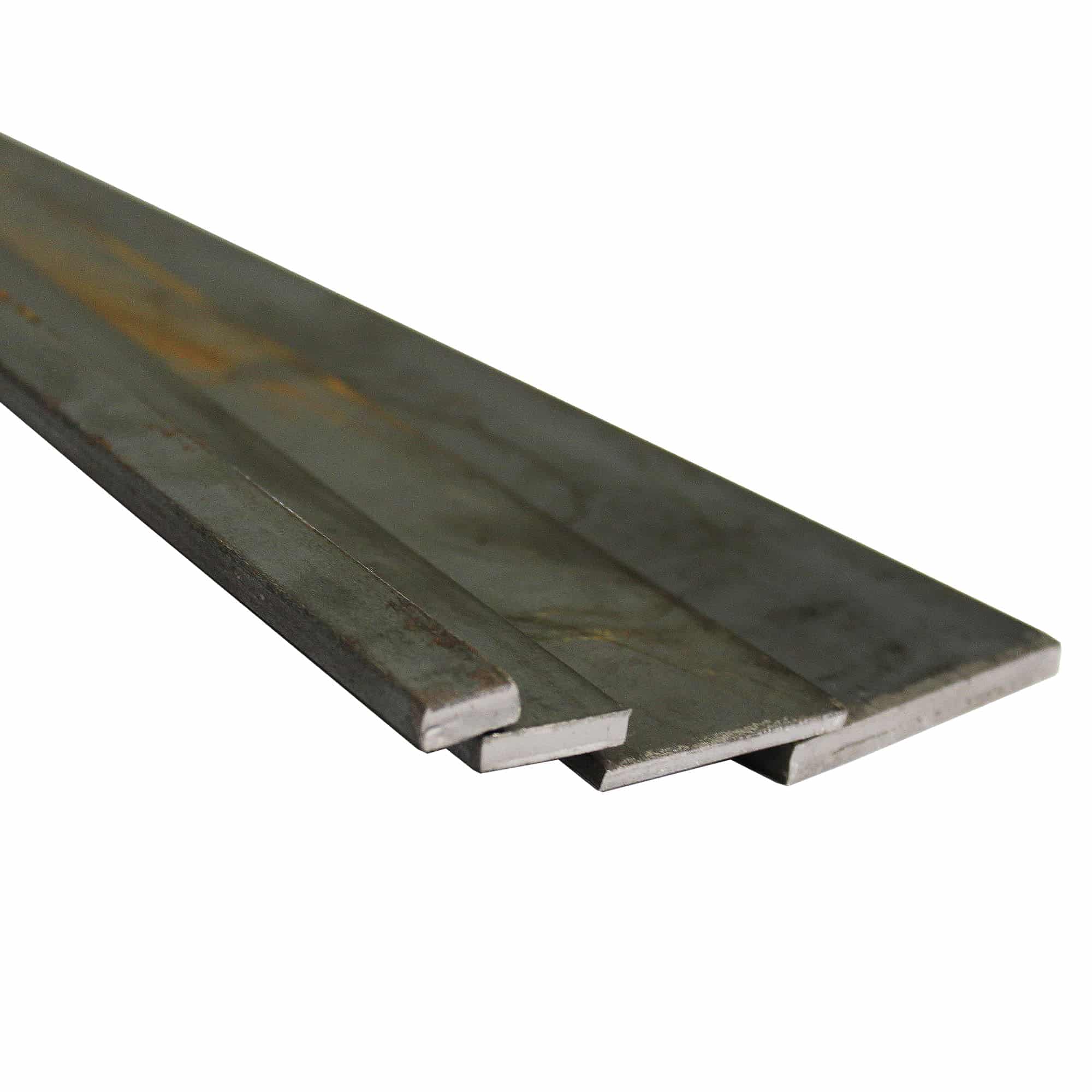

Flat bar is an essential material perfect for constructing with due to it’s versatility. It’s usually made from mild steel because it has great formality and weldability due to its carbon content however it can also be made from aluminium and stainless steel.

What makes steel bar an ideal product for building is that it has a solid, robust structure. There’s also lots you can do with it especially when made from mild steel, it’s has great welding, forming and machining abilities.

Because of its flexibility, there are many ways in which you can utilize steel flat bars, here are some of the most common uses:

Steel flat bar is usually made from mild steel, also known as plain steel. Mild steel is a type of carbon steel, this makes it better for construction which is what flat bar is mostly used for. Plain steel has excellent weldability and is the best metal for bending and forming. It can also be cut down easily and painted over.

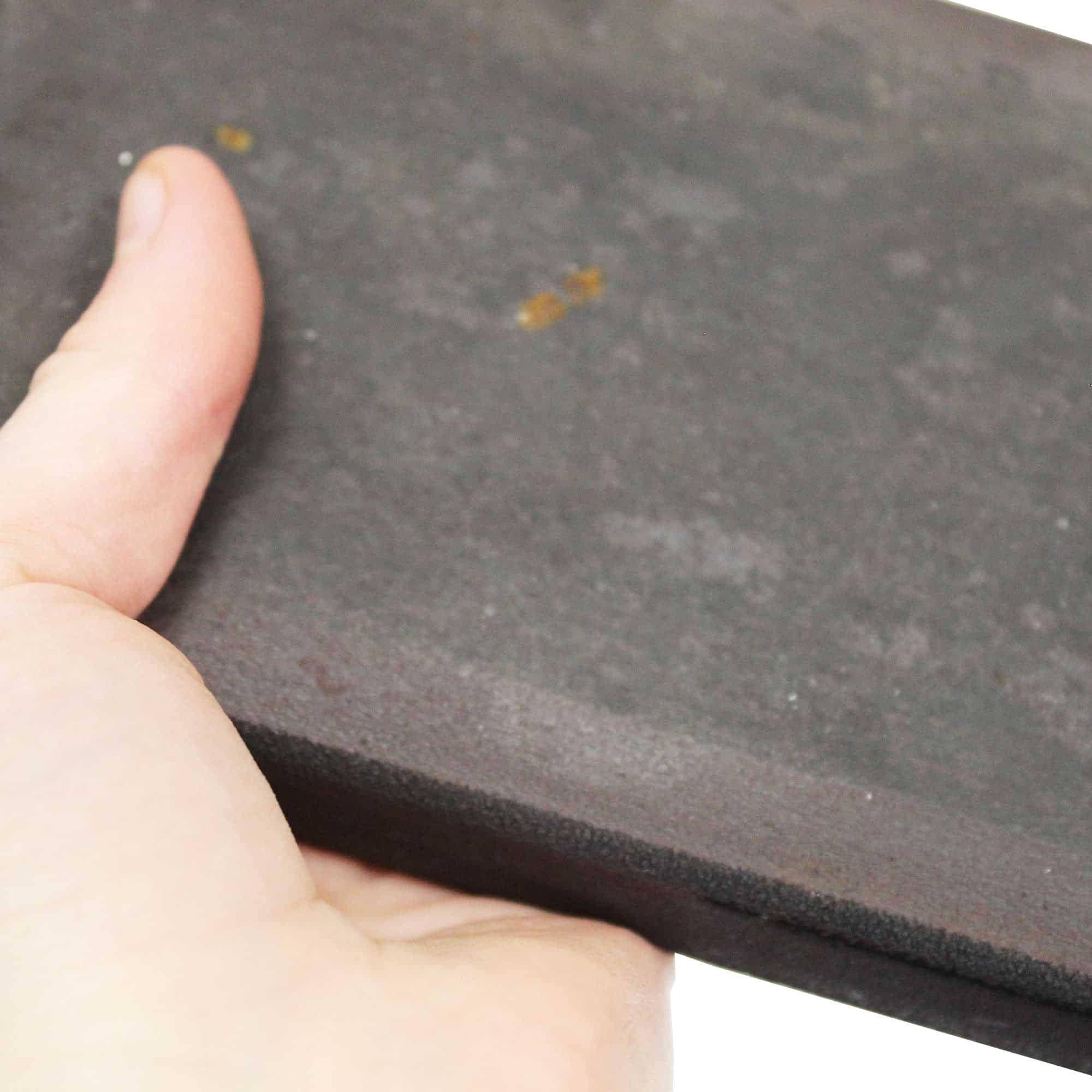

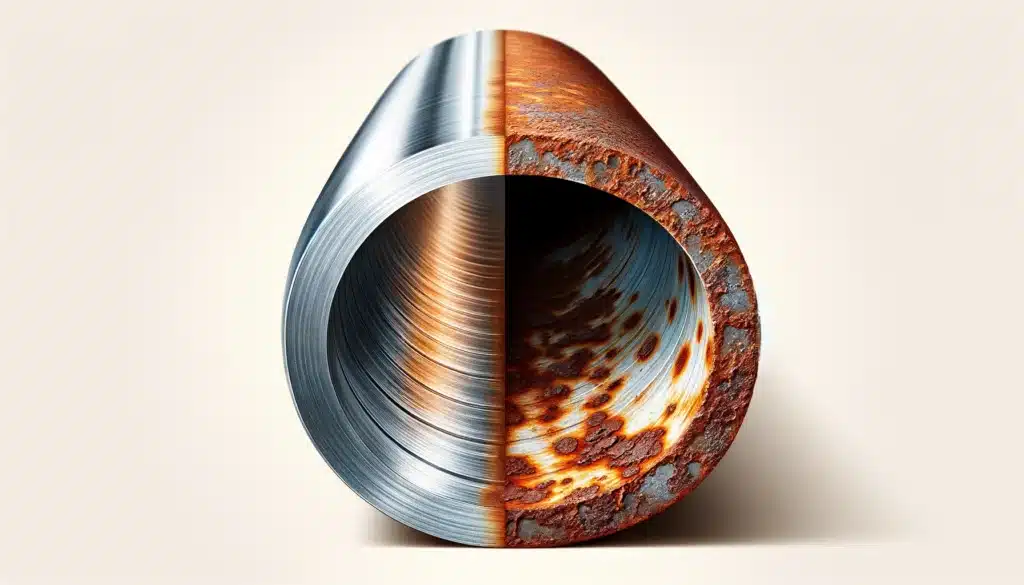

Mild steel is a strong, pure metal consisting of a small amount of carbon and no other combined alloys. This makes mild steel a durable and versatile material as there are lots you can do with it. It also contains no protective coatings therefore it can be galvanised or painted over to add a layer of protection. However, as there is no protection against rusting, mild steel is therefore not resistant to corrosion and will erode over time.

Furthermore, it may leave a rough surface once it begins to rust but it’s easily removable with fine sanding or WD40.

Another metal flat bar is made in is aluminium.

Aluminium is great as flat bar as it’s incredibly lightweight and easy to use. An advantage that aluminium has over mild steel is that it’s resistant to corrosion and will not react to chemicals, water and harsh weather conditions.

This metal is yet another versatile metal because it’s great for outdoor use and it will last a long time. It also has an attractive appearance however aluminium isn’t as strong as mild steel might be in terms of its durability. This is because aluminium can dent or scratch easier than mild steel, it’s also more expensive.

Lastly, flat bar can also be made from stainless steel. This isn’t as common as mild steel for flat bar but it’s longer lasting and resistant to corrosion.

Stainless steel is essentially iron combined with chromium and a little bit of nickel, making it a very strong compound. It reacts to very few elements unlike plain steel. It’s corrosion resistant and will not rust, it’s also weatherproof and will last a long time.

However, stainless steel is more expensive than plain steel. Stainless steel is also not as versatile so it’s harder to weld, form and bend due to its added strength from other alloys but it’s not impossible.

Another reason as to why flat bar is so versatile is because it’s easy to bend. Flat bars can be made into angular iron. This is when the flat bar has been hot rolled and bent into a 90 degree right angle down the centre creating angle bar. Angle bar is another versatile material perfect for constructing with.

To bend a strip of steel bar, it get’s put through a process called hot-rolling process. This is a technique where the strip of steel bar gets heated to a very high temperature of typically around 926 degrees Celsius so that it becomes malleable. It’s then inserted into a heated mill and gets rolled down the centre until it forms the necessary angle. It’s then left to cool to room temperature.

There is also another method called the cold rolling process, it’s practically the same as the hot rolling process however the metal isn’t initially heated. The metal is instead rolled at room temperature, this method however is more expensive and labour-intensive as it’s much more time consuming to bend the metal.

There are a couple of ways that flat bars can be cut down, it just depends on the thickness of the strip.

For thinner flat bar strips (up to 6mm thick), it can be cut down with an industrial guillotine, also used for cutting down metal sheets. For thicker strips (over 6mm thick) they are cut down with an ultra-powerful industrial saw which can cut down flatbar as thick as 20mm.

As we supply a wide variety of flat bar, normally they come in 5 metre strips. However for storage reasons, we guillotine down the flat metal strips into 1 metres lengths.

We supply our flat bar in no longer than 1 metre lengths but it can be cut down further into smaller lengths if required.

To answer your question on using flat bar as a lintel, it’s known to NOT be useful for a lintel. If you need a metal lintel, it’s ideal to use angular bar. This is similar to flat bars but it’s been hot-rolled into a 90 degree right angle down the centre.

Also make sure that the metal you are using is stainless. Therefore using either stainless steel, galvanised steel or aluminium as they do not rust unlike plain mild steel.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options