- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » An In-Depth Guide to Choosing and Using Round Aluminum Tubes

Aluminium, known for its lightweight yet strong nature, is a staple in various industries, from construction to aerospace, automotive to marine.

The secret to its ubiquity lies in its unique combination of properties: corrosion resistance, excellent conductivity, and remarkable flexibility in design.

Aluminium round tubes, particularly, stand out in the market due to their ease of installation and long-term durability, making them a favoured choice for structural and design applications alike.

We have written this article to discuss its versatility, potential applications, manufacturing process and more.

Let’s go…

At Speciality Metals, we understand the critical role these tubes play in your projects.

That’s why we offer a comprehensive range, crafted to meet the highest standards of quality and performance.

A variety of sizes and grades are available, each tailored to meet the specific needs of the industry. No matter what you’re building, our aluminium tubes provide the quality and reliability you need.

There’s a good reason why aluminium has such a stellar reputation in tubing applications. The material boasts an unparalleled strength-to-weight ratio, which is essential for applications that require lightweight materials without sacrificing strength. As a result, aluminium tubes are an excellent choice for projects where weight reduction is paramount, such as in the transportation sector or the development of sustainable construction materials.

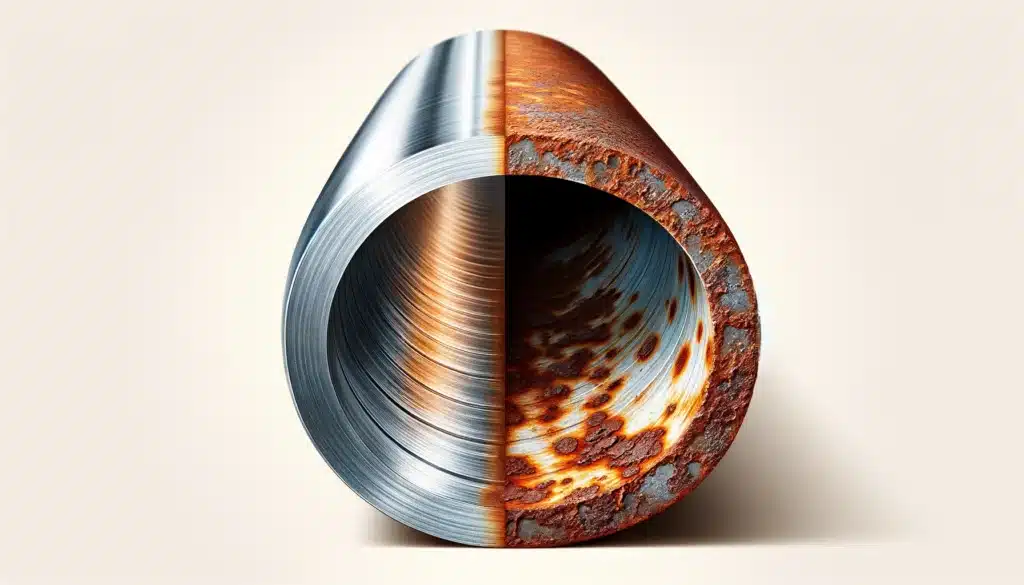

Furthermore, aluminium is naturally corrosion-resistant, making aluminium tubes more durable and requiring less maintenance over their lifetime than other materials. In chemical processing plants or outdoor installations, corrosion resistance is especially important in environments exposed to moisture and chemicals.

Aside from the thermal and electrical conductivity of aluminium, it also opens up a whole new world of applications. Aluminium tubes provide an efficient pathway for the transfer of heat in industries where heat exchange is critical, such as in HVAC systems or automotive cooling systems where heat exchange is critical. Even though the conductivity of aluminium tubes is not as high as that of copper, it is still significantly better than that of other metals, which makes them an attractive option for electrical conduits because of their low cost.

It is also important to note that aluminium tubes have the advantage of being adaptable. It is easy to cut, bend, and shape these different types of metals to fit custom designs, which is why they are used extensively in the fabrication industry. In addition to being able to bend to the will of innovation, aluminium tubes are capable of taking on the most precise requirements of aviation and automotive components as well as the artistic curves of modern architecture.

There are many reasons why aluminum tubes are not only versatile; they are also a sustainable option. The aluminium metal is 100% recyclable, and its recycling process consumes only 5% of the energy it took to produce it in the first place. As a result, aluminum tubes are able to close the loop on their life cycle, making them an environmentally friendly choice in an increasingly eco-conscious world.

Aluminium round tubes come in various types, each tailored to specific applications and structural requirements. At Speciality Metals, our range includes:

Each type of aluminium round tube in our inventory is meticulously crafted to meet diverse project demands. As a result, the specifications vary from model to model, with sizes ranging from small diameter tubes suitable for intricate machinery to large, robust tubes used in construction. As a result, we offer a range of wall thicknesses to ensure that we can provide the precise level of strength and flexibility that you require.

It is also important to note that aluminium round tubes come in different grades, each of which offers its own advantages. It is for this reason that our 6061-T6 aluminium tubes are particularly popular in structural applications due to their high tensile strength, while our 3003-H14 aluminium tubes provide superior formability and are frequently used in automotive components.

The manufacturing of aluminium round tubes is a process we refine continually to ensure the highest quality. To create the desired shape and size, premium-grade aluminium billets are heated and extruded through a die. As a result, seamless construction and consistent wall thickness are ensured.

Seamless tubes are made from extruded aluminium that is further refined using a drawing method to enhance their properties. Tubes are often subjected to high pressures, so this step is crucial.

Quality doesn’t end with the manufacturing process. Speciality Metals places a high priority on quality control. Our aluminium tubes undergo rigorous testing throughout the production cycle to meet the high standards expected by our clients. Testing includes dimensional verification, mechanical property testing, and surface finish testing.

Furthermore, our products are not only of high quality but are also consistently reliable because we adhere to internationally recognised standards and certifications. From raw material selection to final inspection, our manufacturing facilities employ the latest technologies and are staffed by skilled technicians.

Our high standards ensure that Speciality Metals’ aluminium round tubes are synonymous with durability and excellence, giving our clients the confidence they need to embark on ambitious projects. In a high-tech installation or a new architectural masterpiece, our tubes are up to the task.

Choosing the right aluminium tube for your project is crucial for ensuring performance and durability. Here’s a guide to help you make an informed decision:

Installation Tips:

Maintenance Techniques:

Aluminium stands as a paragon of sustainability in the materials sector due to its infinite recyclability. Due to recycling efforts, nearly 75% of all aluminium ever produced is still in use today. Speciality Metals is deeply committed to this cycle of renewal. Our aluminium tubes are not only made from recycled material when possible, but are also designed to be easily recyclable.

This commitment reduces the demand for primary aluminium, which in turn decreases energy consumption and minimises our carbon footprint. By choosing our aluminium tubes, you’re not just investing in the quality and performance of your projects but also contributing in some way to a greener planet.

With the help of this guide, we’ve explored the versatile world of aluminium round tubes, exploring their benefits, types, and meticulous manufacturing process. We have provided you with the tools to select the perfect tube for your project and outlined best practices for installation and maintenance. Additionally, we have aligned our practices with the global push for recyclability.

Don’t let your projects wait any longer. Now is the time to elevate them with the strength, precision, and sustainability of aluminium round tubes.

To view our full range of sizes, grades, and specifications, visit our Aluminium Round Tube product page. Whether you’re an engineer, an architect, or a DIY enthusiast, we have the perfect solution for you. Speciality Metals is your trusted partner in aluminium tube supply, so place your order today.

Join us in shaping a durable and sustainable future—one aluminium tube at a time.

Also, if you have used our metals for your project and want us to display it through our site or social media then please just get in touch. As you can see by the volume and detail in our articles, we love creating content for our customers.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options