- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Stainless Steel Sheet Metal: A Helpful Guide

At Speciality Metals, we have a lot of products to choose from. There are so many questions about applications, lifespans, etc that need to be asked and answered that we have set up a twice weekly series of guides. Hopefully this will give you an idea of what’s possible and what’s needed for every requirement.

One of the most popular products that we stock is rectangular tube. We hope that this guide can answer some of the questions to help you to decide on whether it is right for your application.

As well as these help guides, please do contact us if you need any assistance at all. We’re always happy to help.

Let’s get into it….

There are many different grades of stainless steel, and the specific grade used for a particular application depends on a variety of factors, including the environment in which the steel will be used, the type of application, and the specific properties required. Some common grades of stainless steel sheet include:

These are just some of the more common grades of stainless steel sheet, there are many other grades available, each with their own unique properties and applications.

We keep it simple and focus mainly on two grades : 304 and 430. 304 because it is the most popular and 430 because it is the most popular which is also magnetic.

This guide will focus on these two options.

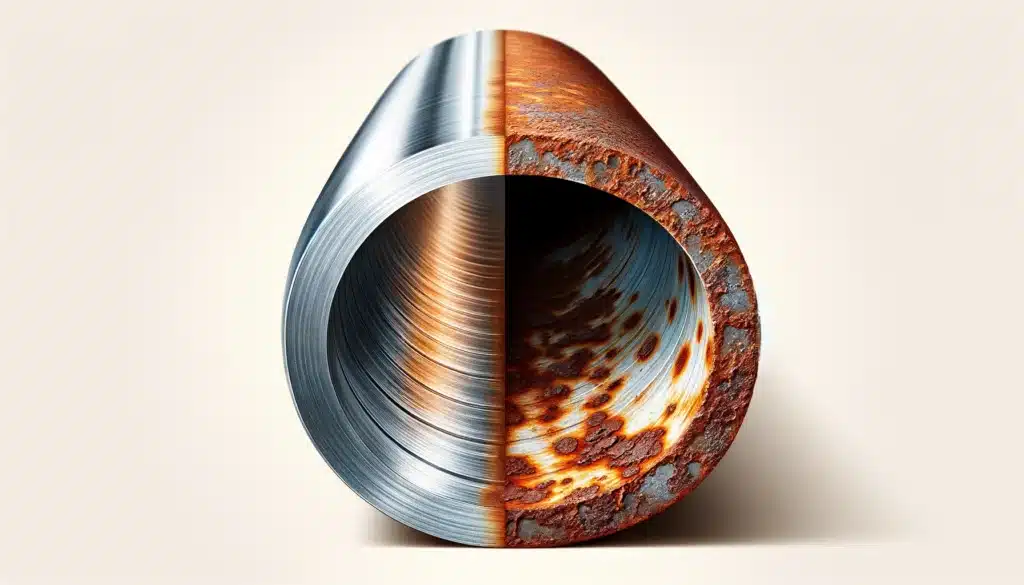

Stainless steel is a type of metal that contains at least 10.5% chromium. There are different types of stainless steel, but most commonly used is the 300 series which is composed of iron, chromium, and nickel. The nickel in the alloy makes it non-magnetic. So most Stainless steel sheet metal is non-magnetic. However, some stainless steel grades such as 400 series may be magnetic.

We offer 430 grade stainless steel which is magnetic.

304 grade stainless steel sheet is commonly used in a variety of applications due to its excellent corrosion resistance, high-temperature resistance, and excellent formability. Some of the common applications for 304 stainless steel sheet include:

430 grade stainless steel sheet is commonly used in a variety of applications due to its excellent corrosion resistance, good formability and its attractive appearance. Some of the common applications for 430 stainless steel sheet include:

Again, it is important to note that 430 grade stainless steel is magnetic, thus it may not be suitable for certain applications that require non-magnetic properties. Additionally, it is not as corrosion resistant as other grades of stainless steel, such as 304 or 316.

Yes, it is possible to weld stainless steel sheet metal using various welding methods, such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and stick welding. Each method has its own advantages and disadvantages, and the appropriate method to use will depend on the specific application, the thickness of the sheet metal, and the desired final result.

TIG welding is a precise and versatile welding method that produces high-quality welds and is commonly used for thin sheet metal and for welding small components.

MIG welding is a faster and more efficient welding method that is commonly used for welding thicker sheet metal and for welding large components.

Stick welding is a less expensive and more portable welding method that is commonly used for welding outdoors and in fieldwork.

It is important to note that welding stainless steel sheet metal requires specialized skills and knowledge, and it is recommended to work with an experienced welder or welding company. Additionally, it is important to use the correct filler metal and to properly clean the metal prior to welding to avoid contamination and ensure a strong, durable weld.

Yes, it is possible to bend, but it requires specialized equipment and techniques. The type of stainless steel, the thickness of the sheet metal, and the degree of bend all affect the ease of bending. Generally, the thicker the sheet metal, the more difficult it is to bend.

There are several methods to bend stainless steel sheet metal, some of the most common methods include:

It is important to note that bending stainless steel sheet metal can cause work hardening and make it more difficult to bend again in the same spot. Thus, it is important to use the correct bending techniques and equipment to avoid cracking or damaging the sheet metal.

Yes, it is possible to paint stainless steel sheet metal, but it requires proper surface preparation and the use of specialized paints. Stainless steel has a natural oxide layer that needs to be removed before painting, otherwise the paint will not adhere properly.

The process of painting stainless steel sheet metal involves several steps:

It is important to note that painting stainless steel sheet metal will change its appearance and may affect its corrosion resistance. Additionally, painting may not last as long as the natural finish of the stainless steel. It is always recommended to consult with professional before starting the process.

In conclusion, stainless steel sheet metal is a remarkable material that offers a wide range of benefits and applications.

Speciality Metals specialise in rapid, fuss-free fulfilment of 304 sheet metal especially.

It offers exceptional corrosion resistance, durability, and versatility, which makes it a top choice for numerous industries, including construction, architecture and automotive.

Whether it’s for architectural features, kitchen appliances, or industrial equipment, stainless steel sheet metal delivers reliability and performance.

With its ease of fabrication, high strength-to-weight ratio, and resistance to heat and chemicals, stainless steel sheet metal continues to be a go-to option for multitudinous projects.

Embracing the qualities of this remarkable material opens up endless possibilities for innovative and enduring designs in both residential and commercial applications.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options