- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Sheet Metal Weight Calculator: A Helpful Guide

So, we have a lot of metal products to choose from. There are so many questions about applications, lifespans, etc. Feel free to contact us if you need any help. We’re always happy to help.

To help our customers further, we’ve also started an epic project to create metal guides. Maybe this will give you an idea of what’s possible and what’s needed for every requirement.

How can I calculate the weight of the metal? That’s one of the most common questions we get.

Let’s talk about it….

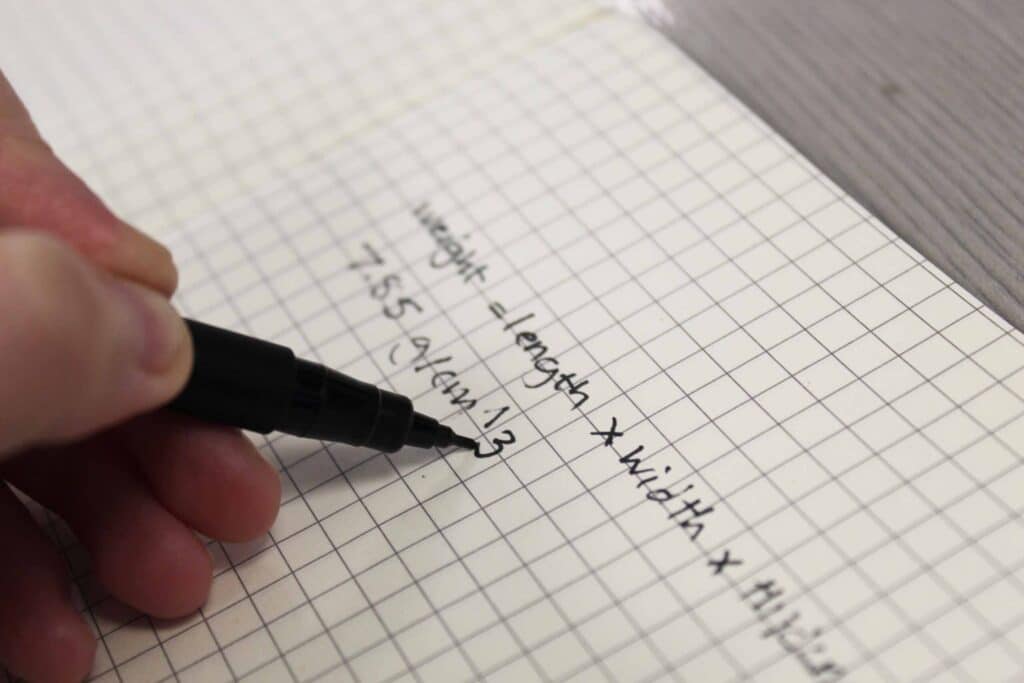

There are several online sheet metal weight calculators that can be used to determine the weight of a sheet of metal based on its thickness, width, and length. These calculators typically require you to input the type of metal (such as steel, aluminium, or copper), the thickness of the sheet in inches or millimetres, the width of the sheet in inches or millimetres, and the length of the sheet in inches or millimetres. Once you have inputted this information, the calculator will provide you with the weight of the sheet in pounds or kilograms.

It’s important to notice that the weight calculation will depend on the metal type density and the material thickness, and width, and length. Some of these calculators are available on some metal suppliers websites, or you can use a third-party calculator such as: https://www.engineeringtoolbox.com/sheet-metal-gauges-d_771.html

To calculate the weight of an aluminium sheet metal, you will need to know the length, width, and thickness of the sheet, as well as the density of aluminium. You can then use the formula: weight = length x width x thickness x density. The density of aluminium is approximately 2.7 g/cm^3 or 0.0975 lbs/in^3.

To calculate the weight of an aluminium checker sheet metal, you will need to know the length, width, and thickness of the sheet, as well as the density of aluminium. Additionally, you need to know the weight of the checker pattern, as the weight will depend on the thickness of the checker pattern.

You can use the formula: weight = (length x width x thickness x density) + (length x width x checker thickness x density). The density of aluminium is approximately 2.7 g/cm^3 or 0.0975 lbs/in^3.

Please note that the checker pattern thickness should be in the same unit as the sheet thickness and density.

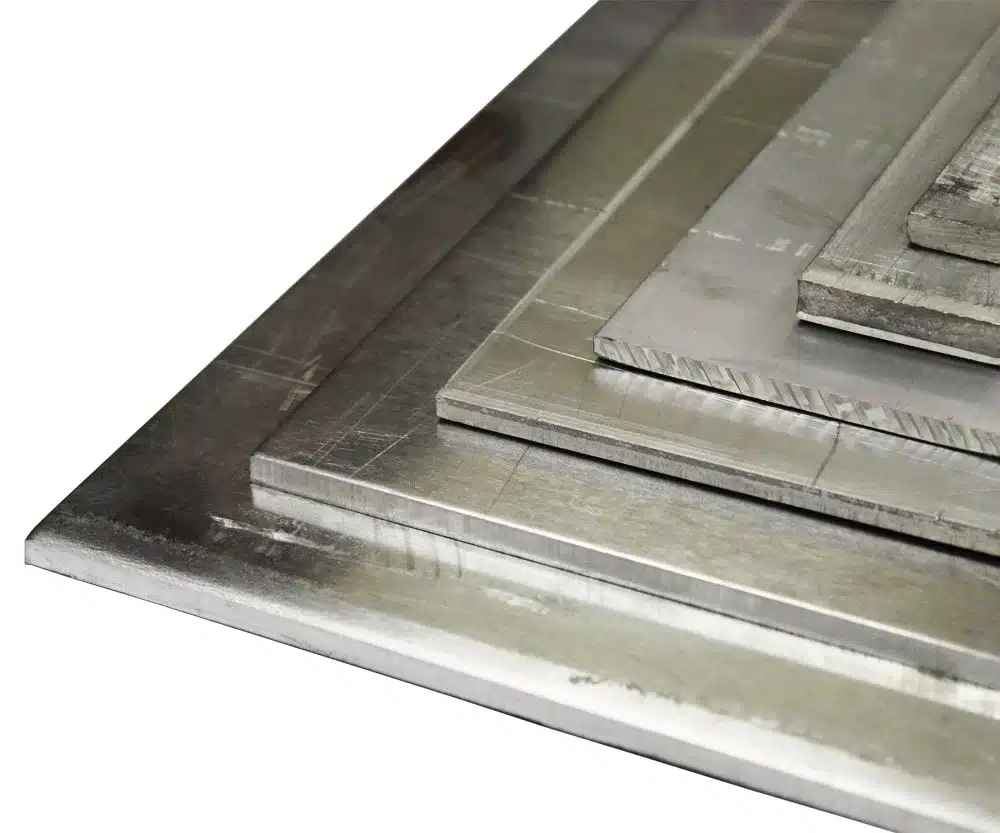

To calculate the weight of a mild steel sheet metal, you will need to know the length, width, and thickness of the sheet, as well as the density of mild steel. You can then use the formula: weight = length x width x thickness x density. The density of mild steel is approximately 7.85 g/cm^3 or 0.284 lbs/in^3.

Please note that mild steel density can vary depending on the composition of the steel alloy.

You can use the formula: weight = length x width x thickness x density. The density of stainless steel varies depending on the type and grade of the steel, but it typically ranges from around 7.75 g/cm^3 to 8.03 g/cm^3 or 0.278 lbs/in^3 to 0.290 lbs/in^3.

It’s important to use the right density value for the specific type and grade of stainless steel you’re working with, as the density can vary significantly between different types and grades.

As with normal sheet metal, to calculate the weight of perforated metal, you will need to know the length, width, thickness, and density of the material, as well as the size and pattern of the perforations.

To calculate the weight of a perforated metal sheet, you can use the formula:

weight = (length x width x thickness x density) – (perforation area x thickness x density)

Where perforation area is the total area of the perforations in the sheet. The density of the material can vary depending on the metal type, example for steel is around 7.85 g/cm^3 or 0.284 lbs/in^3, for aluminium is approximately 2.7 g/cm^3 or 0.0975 lbs/in^3.

It’s important to have the perforation area as a percentage or in square units, so you can subtract it from the total weight. Also, make sure that the dimensions, thickness and density are in the same units for accurate calculation.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options