- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » How to Calculate Ductility: A Comprehensive Guide by Speciality Metals

Ductility is one of the most important material properties to consider when working with metals. It describes a metal’s ability to stretch or deform without breaking, making it an essential factor in applications requiring flexibility, strength, and durability. For industries ranging from construction and manufacturing to automotive and aerospace, understanding ductility is crucial to selecting the right material for the job.

At Speciality Metals, we pride ourselves on offering a range of high-quality metals, including mild steel, aluminium, and stainless steel, which cater to a wide variety of projects. Whether you’re working with sheet metal, round tubes, or flat bars, knowing the ductility of the material is key to ensuring success in your designs and builds.

In this guide, we’ll explore what ductility is, how it’s measured, and why it’s important for metalworking projects.

We’ll also provide practical examples and tips to help you evaluate ductility, with specific focus on the materials we supply. If you’re using metals from Speciality Metals, this article will ensure you can confidently assess their properties and make the most of their capabilities.

1. Why is ductility important in metalworking?

Ductility ensures that metals can deform without breaking, making them ideal for bending, shaping, or forming.

2. Which metal is the most ductile?

Aluminium is one of the most ductile metals, followed closely by mild steel.

3. Can ductility be improved?

Yes, through heat treatment or alloying with other elements.

4. Are ductile metals weaker?

Not necessarily. Many ductile metals, like mild steel, offer an excellent balance of strength and flexibility.

Ductility is a measure of a material’s ability to deform under tensile stress without breaking. Simply put, it describes how much a material can stretch before it fractures.

A highly ductile material can be stretched into wires, drawn into shapes, or formed without cracking—making it ideal for projects that require flexibility or durability.

Key Indicators of Ductility:

Materials like aluminium and mild steel are well-known for their ductility, making them popular in a wide range of applications. Aluminium, for example, is lightweight and highly malleable, making it perfect for intricate designs in sheet metal and U channels. Mild steel, on the other hand, is strong and versatile, allowing it to bend and stretch in heavy-duty projects.

In contrast, materials like cast iron are brittle and have very low ductility, making them unsuitable for applications that require deformation or bending.

At Speciality Metals, we offer a range of metals with varying levels of ductility, ensuring there’s always a material to suit your specific needs.

From 3mm mild steel sheet for structural applications to aluminium T sections for lightweight, flexible designs, our products are designed to meet the highest standards of quality and performance.

Measuring ductility is essential for understanding how a material will perform under stress. The most common method for determining ductility is tensile testing, which involves pulling a metal sample until it fractures.

Steps in Tensile Testing:

Example Calculations for Ductility:

For instance, a mild steel flat bar from Speciality Metals might elongate by 25% under tensile stress, showcasing its excellent ductility. Similarly, our aluminium round tubes often exhibit even higher elongation percentages, making them ideal for projects requiring flexibility.

Ductile metals are crucial for projects that involve forming, bending, or stretching. Here’s how our materials excel in various applications:

Construction:

Automotive and Aerospace:

Manufacturing:

While ductility is a vital property, it’s essential to consider how it compares to other material characteristics like strength, hardness, and toughness.

Ductility vs. Strength:

Ductility vs. Hardness:

Ductility vs. Toughness:

Ductility is a critical property that determines how metals behave under stress, making it essential for projects requiring bending, forming, or stretching. At Speciality Metals, we’re proud to offer a range of high-quality materials, including mild steel, aluminium, and stainless steel, all designed to meet your specific project needs.

By understanding ductility and how to measure it, you can choose the right metal for your application, whether it’s a lightweight aluminium U channel for a creative project or a robust mild steel sheet for structural reinforcement.

Explore our full range of ductile metals today and experience the quality and versatility that Speciality Metals brings to every project. If you have any questions or need expert advice, don’t hesitate to reach out—we’re here to help!

As always, thank you for checking out our blog. We hope that this helps you with your project.

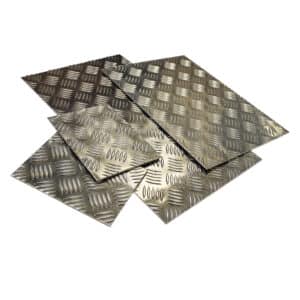

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options