- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Frequently Asked Questions About Aluminium Sheet Metal

From construction to automotive, aluminum sheet metal is known for its lightweight and durability. To effectively utilise it, one must understand the processes involved in its creation and manipulation.

In this article, we explore frequently asked questions about aluminium sheet metal, including how it’s made, cut, cleaned, bent, joined, and even painted. Whether you’re a professional or a DIY enthusiast, these insights will help you handle aluminium sheet metal with confidence.

Let’s go..

Aluminium sheet is made by a process called rolling, which involves passing an aluminium ingot through a series of rollers to achieve the desired thickness and dimensions.

As part of this process, molten aluminium is poured into moulds to form ingots. Ingots are the raw material from which sheets are made, and once cooled and solidified, they move on to the next critical step.

The ingots are then subjected to preheating in a furnace, typically reaching temperatures around 450-500°C. The purpose of this step is to make the aluminium more pliable, preparing it for the crucial rolling phase. As these heated ingots are rolled, they pass through a series of rolling mills. It’s a progressive process where each mill reduces the thickness of the aluminium, simultaneously extending its length. Several sets of rollers thin the metal systematically to achieve the desired sheet thickness in rolling mills.

After rolling, the aluminium may undergo annealing. By reducing residual stress in the metal, it enhances its strength and ductility. In annealing, the metal is heated to a high temperature and then cooled under controlled conditions. The final step is to trim the aluminium plate to specific sizes and shapes. Additional treatments, such as polishing or coating, may improve the metal’s appearance and provide corrosion protection.

A variety of methods are available for cutting aluminium sheet, each suited to a different thickness and requirement. Circular saws and jigsaws with metal-cutting blades are commonly used for straight cuts. During cutting, it is important to clamp the sheet securely to a stable work surface.

A jigsaw fitted with a metal-cutting blade or a rotary tool fitted with a metal-cutting disc is often used to make curved cuts in aluminium sheet. You should first outline the desired curve on the sheet using a marker, providing a visual guide to follow when cutting.

Power shears present another method for cutting aluminium sheets. These specialised tools, designed specifically for cutting sheet metal, can be manual, pneumatic, or electric. The ability to make straight and curved cuts makes them a valuable tool when working with sheet metal. In larger projects where efficiency and precision are crucial, power shears are particularly effective.

Manual snips, also known as aviation snips, are useful for smaller, more precise cuts. Designed for detailed work, these handheld tools offer fine control over cutting. They are available in a variety of shapes and designs, each tailored to different types of cuts. Manual snips, however, are generally recommended for thinner aluminium sheets, typically no thicker than 1mm, because their cutting capacity is limited.

No matter how aluminium sheet is cut, it is important to consider its thickness and the nature of the cut. In addition to ensuring the quality of the cut, this also ensures safety and ease of cutting. To prevent injuries, proper safety gear, such as gloves and eye protection, should always be worn.

Checklist for Cutting Aluminium Sheet:

Cleaning an aluminium sheet can be a relatively easy task. Here are some steps you can follow:

We recommend that you use a sheet metal brake:

If you do not have access to a sheet metal brake, you can also use a vice or a hammer to bend aluminium sheet. However, these methods may require more skill and precision to achieve a clean, accurate bend.

Yes, but you have to choose the right thickness. The general thinking is that it is possible with anything 3mm or less. Even this may prove to be a struggle.

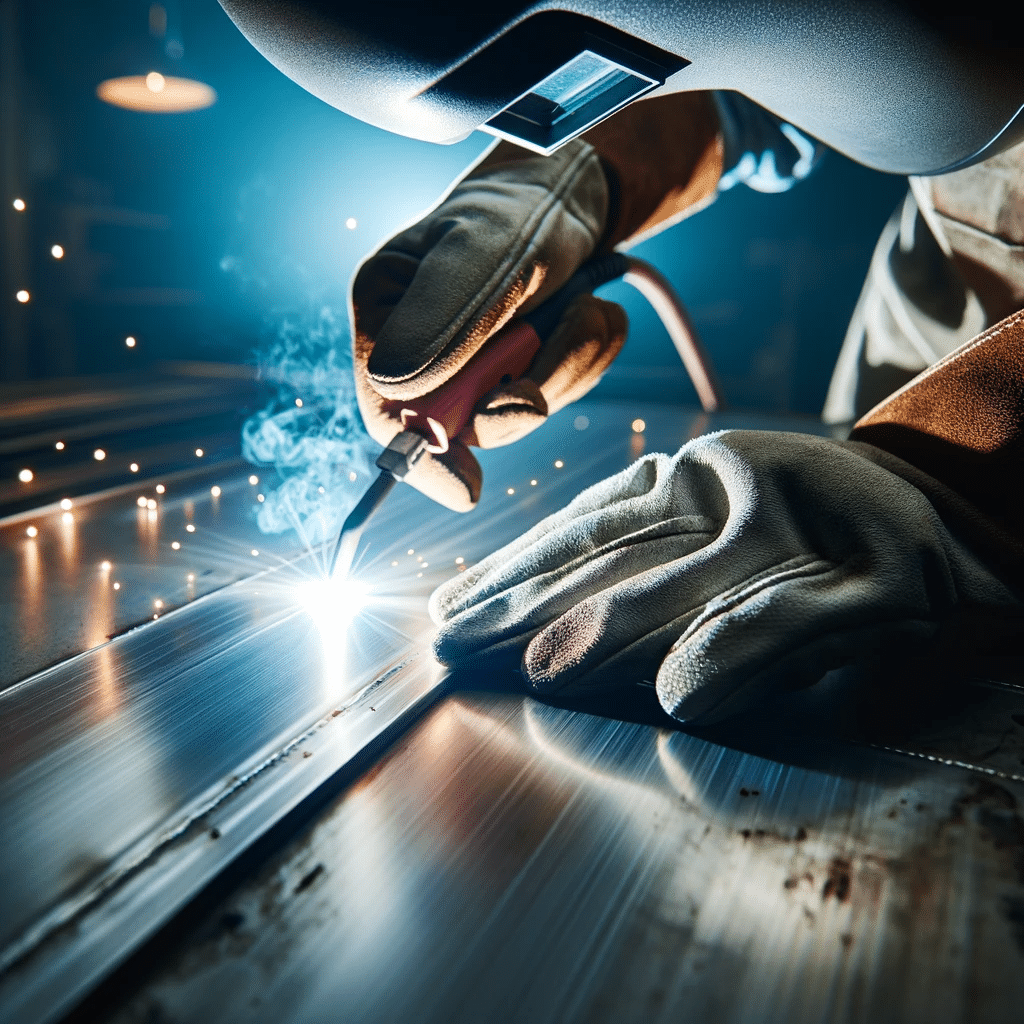

Here are some common methods:

Painting aluminium can be a bit challenging, but it is possible with the right preparation and techniques. Here are the steps to paint aluminium sheet metal:

From the initial steps of making aluminium sheet to the final stages of painting it, each process requires specific techniques and considerations. Having a thorough understanding of these methods ensures the longevity and effectiveness of the material, as well as opening up new applications.

Regardless of the size or scope of your project, the ability to cut, clean, bend, join, and paint aluminium sheet metal is invaluable.

Using this guide, you will be able to harness the full potential of this remarkable material on your next project.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options