- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Benefits of Galvanised Steel in Everyday Products

In today’s world of advanced manufacturing and construction, the materials we choose play a pivotal role in ensuring the longevity, durability and safety of the products and structures we depend on. One such marvel of modern material engineering is galvanised steel. It’s not a new technology, but its applications have grown significantly over the years. In this blog, we will delve into the many benefits of galvanised steel in everyday products.

At its core, galvanised steel is the result of coating steel or iron with a layer of zinc. This process is primarily done to prevent rusting and corrosion. The most common method of galvanising is hot-dip galvanisation, where the steel is submerged in molten zinc.

From the world of construction to daily utility items, the application of galvanised steel is vast. Here are a few:

Construction: It’s used in building frames, railings and protective barriers.

Automobile Industry: Car parts and bodies benefit from the anti-corrosive properties of galvanised steel.

Home Products: From garden fencing, guttering systems to some appliances, the presence of galvanised steel ensures longevity.

Electrical Utilities: Utility poles, brackets and other electrical infrastructure components are often made from galvanised steel for durability.

Agriculture: Tools, machinery and even storage structures in farms often feature galvanised steel.

Corrosion Resistance: One of the standout benefits of galvanised steel is its resistance to corrosion. The zinc layer acts as a sacrificial anode, which means it corrodes before the underlying steel does. This ensures that the product remains rust-free for a more extended period compared to non-galvanised counterparts.

Durability: Products made from galvanised steel tend to have an extended lifespan. The zinc layer provides an extra level of protection against wear and tear, environmental factors and physical impacts.

Cost-Effective: While the initial cost might be slightly higher than non-galvanised steel, the longevity and reduced maintenance needs make galvanised steel more cost-effective in the long run.

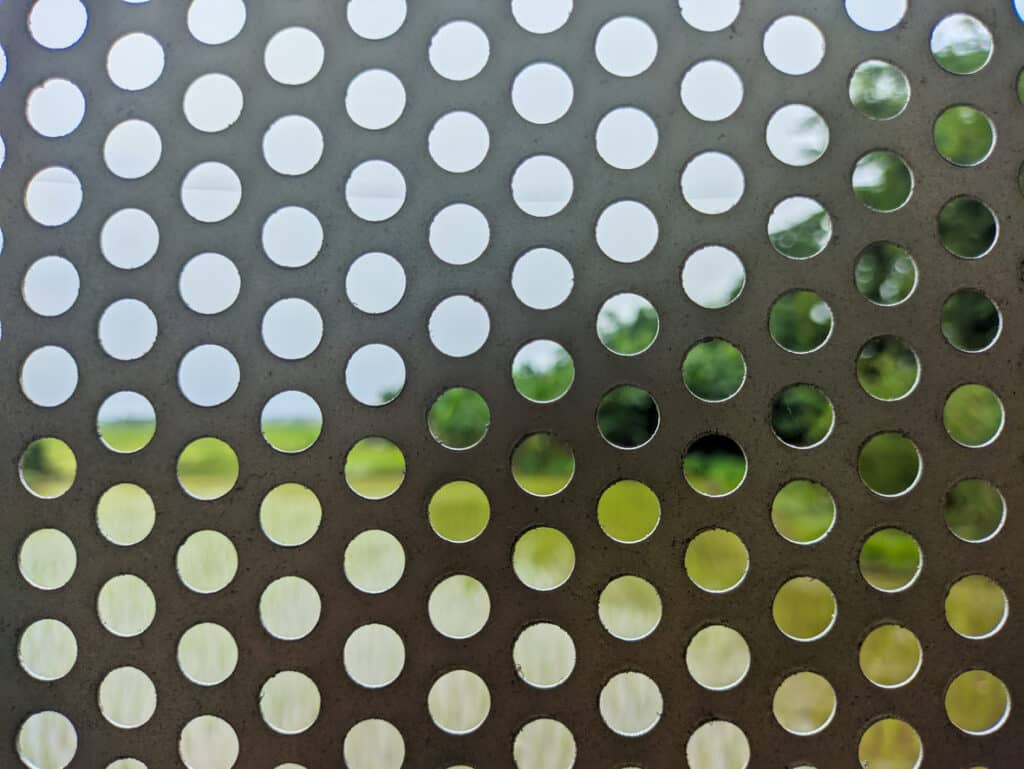

Protection Across the Surface: During the galvanising process, even the smallest nooks, crannies and corners get coated with zinc. This ensures that every inch of the product receives protection from environmental factors.

Environmental Benefits: Given that galvanised steel products last longer, the frequency of replacements is reduced, leading to less waste. Furthermore, steel is recyclable, making galvanised steel an environmentally friendly choice.

Aesthetic Appeal: Over time, galvanised steel can develop a unique patina that many find visually appealing. It can blend well with modern, industrial or rustic designs, giving designers more flexibility.

Easy Inspection: It’s easy to determine if a product is galvanised just by looking at it. The characteristic shine and texture make it stand out. Moreover, thickness tests can be performed quickly to check the quality of the galvanisation.

Hot-dip galvanisation is a process where clean steel pieces are immersed into a bath of molten zinc to obtain a protective outer layer. Initially, the steel is prepared by undergoing a thorough cleaning to remove any impurities, oils or mill scale, typically through a series of caustic cleaning, pickling in acid and fluxing. Once prepared, the steel is submerged into a kettle of molten zinc, typically at temperatures around 450°C (842°F). This immersion results in a metallurgical reaction between the steel and zinc, producing an alloyed layer on the steel’s surface. Once removed from the bath and cooled, the steel is encased in a durable, protective layer of zinc that offers exceptional resistance against corrosion.

Limited Service Life in Aggressive Environments: While the zinc coating provides excellent protection against corrosion, it isn’t infinite. In highly corrosive environments, such as coastal areas with high salinity or industrial areas with high acidity, the zinc can corrode faster, shortening the service life of the galvanised steel.

Appearance Changes Over Time: Over time, galvanised steel can lose its shine and may develop a dull, matte gray appearance or a spangled pattern. This can be a concern for projects where aesthetics are crucial.

Welding Challenges: Welding galvanised steel requires special precautions. The zinc coating can produce toxic fumes when heated. Additionally, welding can burn away the zinc coating, leaving the area vulnerable to rust if not properly re-coated.

Poor Paint Adhesion: If you plan to paint galvanised steel, special primers and preparations are needed. Directly applying paint without appropriate preparation can lead to poor adhesion and peeling.

Reactivity with Other Metals: When galvanised steel comes in contact with certain metals, like copper or brass, it can accelerate corrosion due to galvanic action. Appropriate precautions, such as using insulating barriers, are essential to prevent this.

Cost: Initial costs for galvanised steel can be higher than non-galvanised steel. However, it’s essential to consider the long-term benefits, such as reduced maintenance and longer service life, when evaluating cost implications.

Thickness Limitations: The hot-dip galvanising process may not be suitable for extremely thick or very thin steel sections. The latter can become brittle due to the heat of the molten zinc.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about ‘painting galvanised steel‘ and ‘how to prevent rust on metal‘ recently so why not check it out.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options