- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » The Comprehensive Guide to Sheet Metal: Understanding Gauges, Types, and Applications

Sheet metal truly is a a cornerstone material. It is ubiquitous in many industries. This is because of its versatility, durability, and adaptability across various disparate applications.

From the sleek exteriors of automobiles to the robust frameworks in architecture, sheet metal’s applications are as diverse as they are essential.

This comprehensive guide introduces the intricacies of sheet metal, focusing on metal gauges, sheet metal types, and their diverse applications. No matter if you are an engineer, a DIY enthusiast, or a professional in the construction industry, this guide will help you make informed decisions.

As we discuss sheet metal gauges and types, we will also illustrate how Speciality Metals’ extensive product range meets your needs perfectly. Join us as we reveal the layers of sheet metal knowledge, seamlessly integrated with top-quality products.

As you can see from our online product range, we tend to use mm as our unit of measurement. But we are often being asked:

“What gauge do I need for my project?”

“What is ….mm as a gauge?”

Well this article and chart should explain all.

In metalworking, sheet metal gauges are crucial, but often misunderstood. It is important to note that the gauge of a sheet metal refers to its thickness, with each gauge number representing a standard thickness measured in millimetres. The measurement is not only a numerical value; it also defines the strength, flexibility, and weight of the metal, affecting its application and usability.

As an analogy, thick gauges are like the robust trunks of trees, offering strength and support, while thin gauges are like the delicate petals of flowers, providing finesse and malleability. From aviation, where lightweight metals are paramount, to construction, where durability is paramount, this difference in thickness is crucial.

In our detailed gauge chart, we will compare gauge numbers and their corresponding thicknesses in millimetres across various materials such as stainless steel, aluminum, and copper. Due to differences in density and composition, gauge numbers vary between materials. But, this is perhaps too specific and what we need to do it give a basic guide of SWG, which is usually what our customers are referring to.

The Standard Wire Gauge (SWG), which is also known as the British Standard Gauge, is most commonly used in the United Kingdom, along with the American Wire Gauge (AWG) in the United States. As well as denoting the thickness of wire, the system is also used to denote the thickness of sheet metal.

This is a simple chart for SWG to inch and mm conversion.

| SWG | Inches | Millimeters |

| 1 | 0.3″ | 7.62mm |

| 2 | 0.276″ | 7.01mm |

| 3 | 0.252″ | 6.401mm |

| 4 | 0.232″ | 5.893mm |

| 5 | 0.212″ | 5.385mm |

| 6 | 0.192″ | 4.877mm |

| 7 | 0.176″ | 4.47mm |

| 8 | 0.16″ | 4.064mm |

| 9 | 0.144″ | 3.658mm |

| 10 | 0.128″ | 3.251mm |

| 11 | 0.116″ | 2.946mm |

| 12 | 0.104″ | 2.642mm |

| 13 | 0.092″ | 2.337mm |

| 14 | 0.08″ | 2.032mm |

| 15 | 0.072″ | 1.829mm |

| 16 | 0.064″ | 1.626mm |

| 17 | 0.056″ | 1.422mm |

| 18 | 0.048″ | 1.219mm |

| 19 | 0.04″ | 1.016mm |

| 20 | 0.036″ | 0.914mm |

| 21 | 0.032″ | 0.813mm |

| 22 | 0.028″ | 0.711mm |

| 23 | 0.024″ | 0.61mm |

| 24 | 0.022″ | 0.559mm |

| 25 | 0.02″ | 0.508mm |

As established, sheet metal, in its various forms, serves as the backbone of numerous industries, each type bringing its unique properties and applications.

Among the most commonly used are Aluminium, Stainless Steel, and Copper, each with distinct characteristics that make them suitable for specific uses.

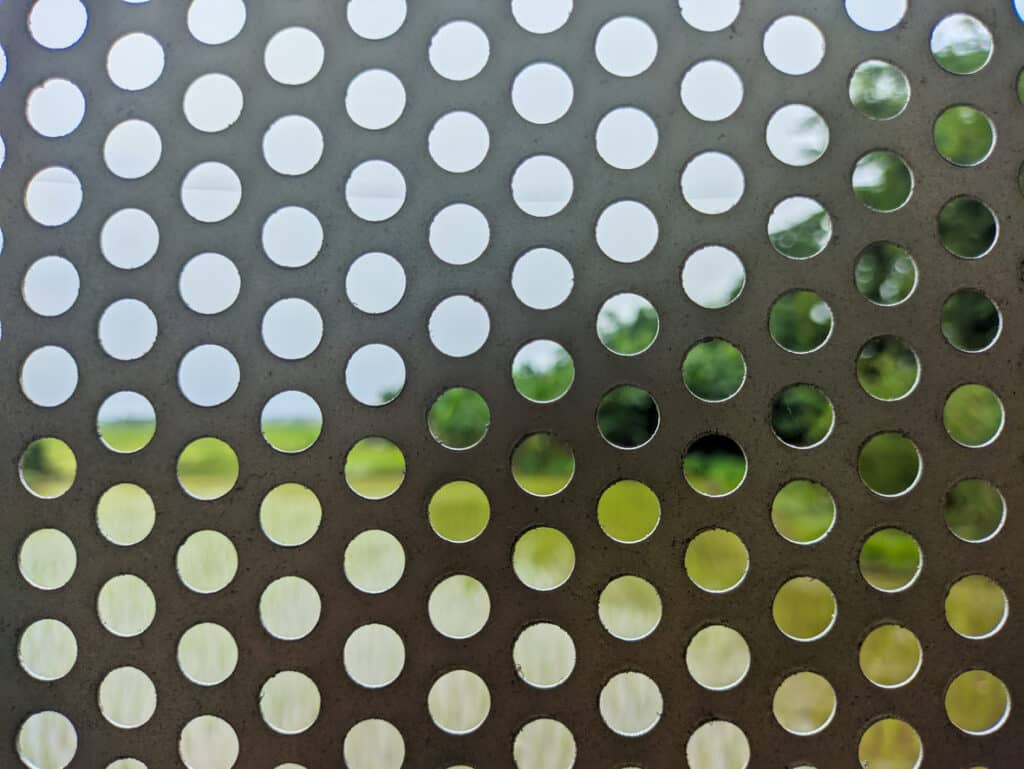

Aluminium Sheet Metal: Aluminium sheet metal is a popular option in industries concerned with weight and durability due to its light weight and corrosion resistance. Due to its malleability, it is ideal for automotive body panels, aircraft components, and architectural facades. Electrical and electronic applications also benefit from aluminum’s ability to conduct electricity. As a result of its reflective nature, it is used in lighting fixtures and insulation.

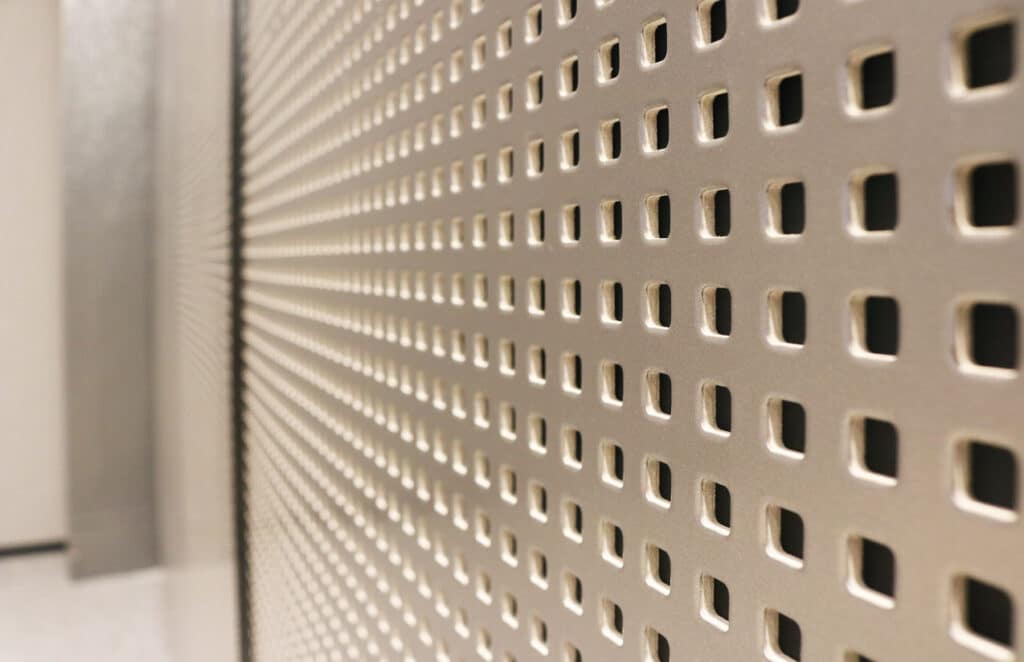

Stainless Steel Sheet Metal: The strength and corrosion resistance of stainless steel make it an ideal choice for applications requiring longevity and minimal maintenance. The type is commonly found in kitchen appliances, medical equipment, and construction materials. Catering and food processing industries choose it for its hygienic properties.

Copper Sheet Metal: In electrical wiring, roofing, and plumbing, copper stands out for its excellent thermal and electrical conductivity. Medical environments benefit from its natural antimicrobial properties. Copper, which gains a unique patina over time, is often used in decorative arts and architecture.

Selecting the right type of sheet metal is crucial, as each project demands specific properties – be it corrosion resistance, strength, conductivity, or aesthetic appeal.

Understanding these properties ensures not only the success and longevity of your project but also cost-effectiveness and efficiency in its execution.

Sheet metal work requires precision, and accurate conversions are the key to this precision. Whether converting gauge numbers to millimetres or inches to millimetres, these calculations ensure that sheet metal aligns perfectly with specifications.

For instance, in a scenario where a design specifies dimensions in inches, but the sheet metal is measured in millimetres, conversion becomes essential. Understanding that 1 inch equals 25.4 millimetres allows for accurate translation of measurements, ensuring the final product meets the required specifications.

To aid in these conversions, Speciality Metals provides a user-friendly online conversion tool. This digital aid simplifies the process of converting between different units, ensuring accuracy and saving valuable time. Such tools are indispensable, especially when dealing with complex projects requiring meticulous attention to detail.

Using our conversion chart, you can easily understand conversions such as gauge to millimetre and inch to millimetre. Using this chart will help you navigate the intricate world of sheet metal measurements with confidence.

We endeavour to publish a few articles every week to help to explain the world of metals and mesh. So keep an eye on our content for more assistive articles that you may find beneficial.

Sheet metal’s remarkable versatility and adaptability have made it a fundamental material in numerous industries, each harnessing its properties in unique ways.

Construction: The construction industry relies heavily on sheet metal for roofing, siding, and HVAC systems. Due to its durability and resistance to environmental factors, it is ideal for exterior building applications. Metals like copper and aluminium are also used in architectural design because of their aesthetic appeal.

Automotive: Body panels are a major use of sheet metal in the automotive industry. Lightweight aluminium contributes to fuel efficiency, while steel’s strength ensures structural integrity and safety. Automotive design and efficiency continue to be enhanced by advances in metal forming technologies.

Aerospace: In aerospace, it is imperative to use materials that can withstand extreme conditions while minimizing weight. Titanium and high-grade aluminium alloys play an important role here. The strength-to-weight ratio of these materials is crucial in the construction of airframes and engine components.

Working with sheet metal involves a variety of techniques and tools, each tailored to the specific type of metal and the intended application. Here are some tips and best practices:

Cutting: Select the appropriate cutting tool based on the metal’s thickness and hardness. Common tools include shears, nibblers, and plasma cutters. Always ensure sharp blades for clean cuts.

Bending: For bending sheet metal, brake presses and folding machines are typically used. Precise angle measurements are crucial for accuracy, particularly in complex fabrications.

Shaping: Techniques like stamping and rolling are used to shape sheet metal into desired forms. Understanding the metal’s malleability and ductility is key to successful shaping without causing damage.

Safety Tips:

Best Practices:

In terms of tools and equipment, Speciality Metals offers a range of options suited for various sheet metal working requirements, ensuring efficiency, safety, and quality in your projects.

When sourcing sheet metal, your supplier’s quality, range, and support can make all the difference. With Speciality Metals, you get not just materials, but complete solutions tailored to your needs. We offer a wide range of high-quality stainless steel, aluminium, copper, brass, and more, all meeting stringent standards to ensure the best results for your projects.

What truly sets Speciality Metals apart is our commitment to custom solutions. Each project has its own unique challenges and requirements. Whether it’s custom cut sizes, specific grades of material, or expert advice on the best type of sheet metal for your project, our team of experts can provide bespoke solutions.

Explore our sheet metal products and discover the Speciality Metals difference. If you have any questions or custom requests, our team is ready to assist you.

Throughout this guide, we’ve explored the most important aspects of sheet metals, from gauges and types to their diverse applications across industries, and essential tips and techniques. The importance of choosing the right sheet metal for your specific needs cannot be overstated, as it is essential to the success and longevity of any project.

We are your go-to partner for all your sheet metal needs with our quality products, custom solutions, and expert support.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options