- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Selecting the Right Metal for High-Temperature Applications

In the realm of industrial applications, the selection of the right metal for high-temperature environments is not just a matter of choice but a crucial decision impacting the efficiency, safety, and longevity of applications.

High-temperature environments pose unique challenges, including extreme heat, potential corrosion, and material degradation. This necessitates a careful selection of metals that can withstand such demanding conditions without compromising their structural integrity or performance.

Understanding the dynamics of high-temperature applications and the properties of metals that thrive in these conditions is vital for industries ranging from aerospace to power generation. The right choice of metal can mean the difference between a successful, enduring application and a potential failure with significant consequences.

This blog aims to delve into the intricacies of selecting metals for high-temperature applications. We will explore what constitutes a high-temperature environment, identify the industries that commonly face these challenges, and discuss the key properties that make certain metals ideal for such conditions. Our goal is to provide valuable insights, guiding you to make informed decisions when choosing metals for high-temperature applications.

Let’s get into it…

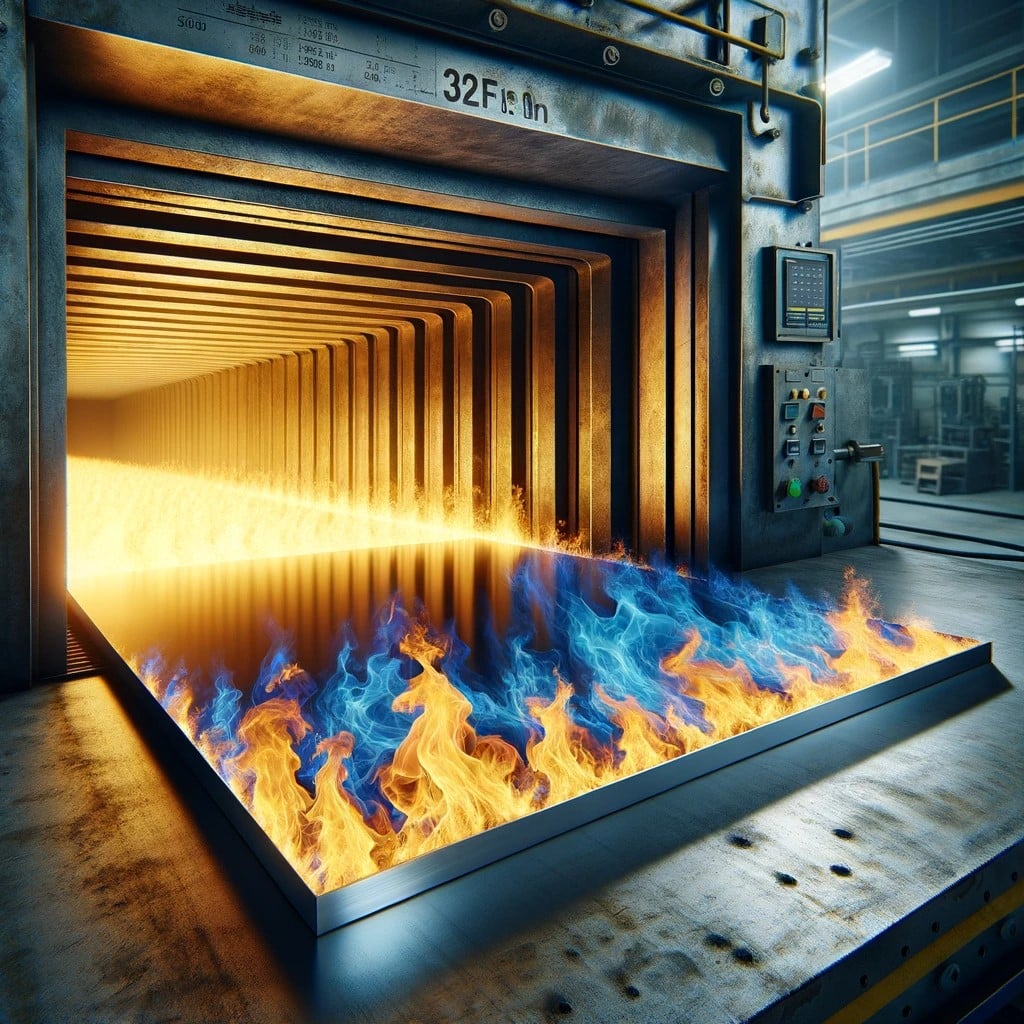

In industrial terms, high-temperature environments refer to settings where materials are exposed to temperatures significantly higher than ambient conditions, usually above 500°F (260°C). It is critical to select appropriate metals for these conditions because these temperatures are intense enough to challenge the structural integrity and performance of conventional materials.

Aerospace, automotive, power generation, petrochemical, and metal processing industries commonly operate in high-temperature environments. Jet engine turbines, for instance, are exposed to extreme temperatures during flight, so metals that can withstand such heat while maintaining strength are required. In the automotive industry, high-temperature metals are required for exhaust systems and engine parts.

The efficient and safe operation of power generation plants, particularly those that use combustion processes, is also dependent on metals that can withstand high temperatures. In the petrochemical industry, chemicals are processed and refined at high temperatures, making the need for suitable metals paramount. Metal processing industries, such as steel and aluminium manufacturing, also involve heat-intensive processes that require metals to remain resilient at elevated temperatures.

Failure to use metals that can withstand high temperatures can result in accelerated degradation, loss of mechanical properties, and even catastrophic failure in these industries. In order to ensure the reliability and safety of industrial applications, it is imperative to understand how high-temperature environments affect materials.

Certain key properties become critical when selecting metals for high-temperature applications. The melting point, thermal conductivity, coefficient of thermal expansion, and corrosion resistance are among them.

The melting point of a metal is the temperature at which it changes from a solid to a liquid state. To maintain strength under extreme heat, metals with high melting points are preferred for high-temperature applications. In environments where intense heat is a constant factor, metals such as tungsten and nickel alloys are often used.

Another important property of metals is their thermal conductivity. A metal with high thermal conductivity can transfer heat quickly, preventing hot spots and maintaining a uniform temperature throughout the component. Applications such as heat exchangers and cooling systems rely heavily on this property.

When heated, a metal’s coefficient of thermal expansion (CTE) increases. Metals with a low CTE are desirable in high-temperature environments since they will experience minimal expansion, reducing the risk of deformation and maintaining their dimensions. For applications such as aerospace and automotive engine components that require precise tolerances, this property is essential.

Corrosion resistance is also important, as high temperatures can accelerate corrosion. When exposed to high temperatures and harsh environments, metals that resist oxidation and corrosion are ideal. The corrosion resistance of stainless steels and certain nickel alloys is excellent at elevated temperatures.

It is fundamental to understand these properties and their impact on metal performance at high temperatures. In addition to withstanding heat, it maintains its mechanical integrity and functional properties when exposed to high temperatures for an extended period of time.

Stainless steel, a metal alloy primarily composed of iron, chromium, and nickel, is exceptionally resistant to heat and corrosion. In spite of temperatures up to about 1100°F (593°C), this metal maintains its structural integrity and appearance. A protective layer of chromium oxide forms on the surface of metals with high chromium content, protecting them from corrosion and oxidation. In harsh environments, stainless steel’s self-healing layer ensures its durability.

High-temperature applications benefit greatly from stainless steel. The material is not only resistant to scaling and retains strength at high temperatures, but is also ductile and tough. Automobiles use it for exhaust systems, aerospace for engine components, and energy for various components in power plants because of these characteristics.

Nickel alloys, including renowned variants like Inconel, are specifically engineered for extreme environments. A nickel-chromium-based superalloy such as Inconel, for instance, can withstand intense heat and corrosive environments. In general, these alloys maintain their tensile strength over a wide temperature range, up to about 2000°F (1093°C).

As a result of the nickel content in these alloys, they are highly resistant to corrosion and oxidation, while chromium contributes to their high-temperature strength. Nickel alloys are therefore suitable for applications in jet engines, gas turbines, and the chemical industry, where high temperatures and corrosive materials are present.

Titanium Alloys

Titanium alloys are celebrated for their high strength-to-weight ratio and outstanding corrosion resistance. While being significantly lighter than steel, they are able to withstand temperatures up to about 600°F (316°C). In addition to titanium’s inherent properties, alloying elements such as aluminium and vanadium enhance its strength and temperature resistance.

As a result of their lightweight and strength, these alloys are commonly used in aerospace for components like compressor blades, discs, and airframes. In addition to naval applications and offshore oil and gas exploration, their resistance to corrosion by sea water makes them valuable.

Tungsten

Tungsten stands out with the highest melting point of all metals, at an impressive 6192°F (3422°C). The combination of this extraordinary feature and its low thermal expansion makes it an ideal material for applications requiring extreme heat resistance. The robustness of tungsten at high temperatures makes it essential for applications such as electrical and aerospace. Due to its ability to remain solid at high temperatures, tungsten is used for filaments in light bulbs and cathodes in electron tubes.

Aerospace Industry: Nickel Alloys in Jet Engines

The aerospace industry is one of the most prominent users of high-temperature metals. A large percentage of jet engine components are made from nickel alloys, including Inconel. General Electric GEnx jet engines, used on Boeing 787 and 747-8 aircraft, utilize Inconel alloys for their high-pressure turbine blades. In addition to being heat and stress resistant, these alloys ensure safety and reliability during flights.

Automotive Industry: Stainless Steel in Exhaust Systems

Exhaust systems in automobiles are commonly made from stainless steel. Ford Mustang exhaust components are made of stainless steel, which is known for its durability and performance. Despite high temperatures produced by engine exhaust gases, this metal is able to resist corrosion and maintain structural integrity.

Medical Industry: Titanium Alloys in Prosthetics

Titanium alloys are widely used in the medical field for prosthetic devices and implants. They are ideal for these applications due to their excellent strength and corrosion resistance, as well as their biocompatibility. Titanium is widely used in hip and knee replacements because of its durability and compatibility with human tissue.

Electronics Industry: Tungsten in Light Bulbs

Due to its high melting point, tungsten is an ideal material for light bulb filaments in the electronics industry. Incandescent light bulbs, which have now been replaced by more energy-efficient alternatives, relied on tungsten filaments because they could withstand high temperatures and emit light without melting.

The choice of the right metal for high-temperature applications is influenced by several key factors. The first consideration is the environment in which the metal will be used. In addition to the temperature range, this includes the presence of corrosive substances, pressure conditions, and exposure to other harsh elements. Due to their excellent corrosion resistance, stainless steel or nickel alloys may be preferred in highly corrosive environments.

Budget is another crucial aspect. It’s important to choose a metal that meets your application’s technical requirements, but cost-effectiveness should not be overlooked. The cost of metals like titanium is high, but they offer exceptional properties. For large-scale or long-term projects, it’s important to balance material benefits with financial feasibility.

Longevity and durability are also paramount. Metals that can withstand the test of time offer better value for money and also reduce maintenance and replacement costs. Consider the long-term performance of the metal in your specific application – a cheaper alternative might end up being more expensive in the long run if it requires frequent replacements.

In the end, the choice should take into account both the technical demands of the application and practical considerations like budget and longevity. In order to make an informed decision that ensures both performance and cost-effectiveness, you must understand the unique properties and costs of different metals.

In order to meet a wide range of industrial requirements, sMetals offers a wide variety of high-temperature metals. We offer premium-grade stainless steel, nickel alloys, titanium alloys, and tungsten, all tailored to specific high-temperature applications.

The stainless steel products we offer are renowned for their corrosion resistance and durability, making them ideal for applications in the automotive and construction industries. In aerospace and chemical processing industries, nickel alloys, including Inconel variants, provide unparalleled strength and resistance to oxidation.

In aerospace and medical applications, titanium alloys are the epitome of strength and lightweight properties. Last but not least, our tungsten offerings stand out in the electronics and aerospace industries thanks to their extraordinary melting point and density.

In addition to being products, these high-temperature metals represent our commitment to quality and innovation. They provide our clients with the assurance of reliability even in the most challenging environments thanks to their durability and performance.

In summary, choosing the right metal for high-temperature applications is crucial to the success and longevity of industrial projects. To make the best choice, it is crucial to understand the unique properties of metals such as stainless steel, nickel alloys, titanium alloys, and tungsten, as well as factors such as environment, budget, and durability.

sMetals provides high-quality metals that meet these diverse needs, ensuring performance and reliability in difficult conditions.

Explore the world of high-performance metals with sMetals.

Explore our extensive range of high-temperature suitable metals, each designed to meet the most demanding industrial demands. Learn more about our products and how they can benefit your projects by visiting our website or contacting us directly. We have a team of experts ready to help you select the right metal solution for your needs.

Get high-temperature metal solutions with quality, durability, and innovation from us today.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options