- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

£29.99 inc VAT

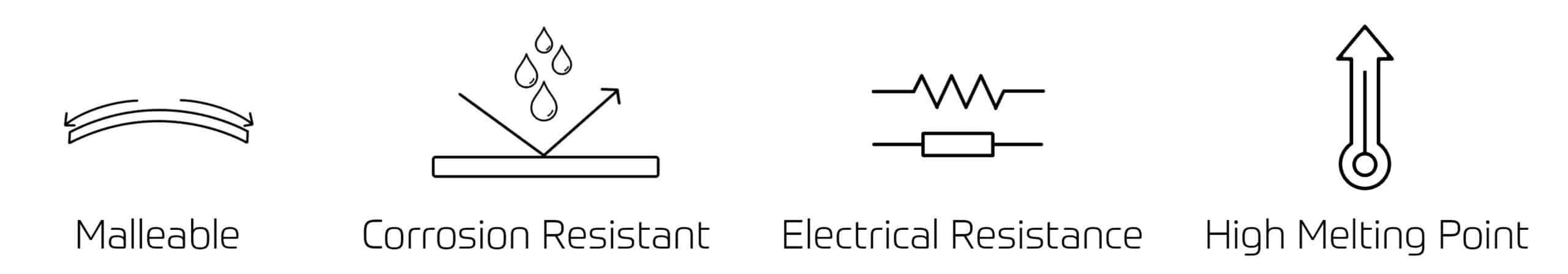

Whether you’re an amateur builder or a professional electrician, nichrome wire is a go-to option when it comes to resistance to heat and electricity. You might be wondering what makes it so special. Well, at 0.6mm thickness and 22 AWG, the Ni80 Nichrome Wire from Speciality Metals is incredibly versatile. With a high melting point, malleability, and resistance to corrosion, it’s an excellent choice for a wide range of applications. Additionally, the rapid heating and quick cool-down make it perfect for those who are looking to save time without sacrificing quality. So whether you’re building a new circuit or working on a creative project, this spool of Ni80 Nichrome Wire is definitely worth considering.

Nichrome wire can be produced with a diameter of 0.05mm to 2mm. We offer these products in a variety of tensile strengths and spool sizes to suit your needs. It is possible to order wires that have been soft annealed or hard drawn.

The Ni80 Nichrome Wire is a versatile metal alloy that is both heat and electricity resistant. This durable wire is able to withstand the intense temperatures required in a wide range of applications due to its high melting point. Additionally, Ni80 Nichrome Wire is malleable and easy to work with, so users can shape it to suit their specific needs. The wire heats up rapidly and cools down quickly, making it ideal for applications requiring rapid thermal response. It is also highly corrosion-resistant, ensuring that it will withstand harsh conditions. This Ni80 Nichrome Wire from specialty metals comes in a sturdy 362g spool with a thickness of 0.6mm / 22 AWG.

Our massive range of wire is courtesy of our relationship with our sister business – Crazy Wire Company. The Crazy Wire Company offer unrivalled range of round, ribbon and flat wire in many spool size options. Our businesses all operate out of the same facility, and our order fulfilment and service are second to none.

The specification of this wire spool is:

We also are the exact suppliers for you because:

Furthermore we stock a vast range of wire options that compliment our mesh range perfectly.

High Resistivity: One of the primary reasons Nichrome is used in heating elements is its high electrical resistivity. This allows it to produce heat when an electric current is passed through it. The resistance of the wire helps convert electrical energy into heat energy.

Oxidation Resistance: When heated in open air, many materials will oxidise rapidly, meaning they’ll corrode or burn out. Nichrome forms a protective layer of chromium oxide, which helps protect the wire from further oxidation, extending its life.

High Melting Point: Nichrome 80 has a melting point of around 1400°C (2552°F), which means it can operate at high temperatures without melting.

Non-magnetic: This can be an important property for specific applications where magnetic interference could be an issue.

Durability: Nichrome 80 wire has a long lifespan due to its resistance to oxidation and other forms of degradation when heated. This makes it a cost-effective choice in applications where the wire will be subjected to frequent heating and cooling cycles.

Stability: The material does not undergo significant expansion or contraction with temperature changes, ensuring consistent performance over its lifespan.

Ease of Fabrication: Nichrome can be easily shaped and welded, making it adaptable to various applications.

Cost: While there are other materials with higher performance specifications in specific areas (e.g., tungsten has a much higher melting point), Nichrome strikes a good balance between performance and cost for most heating applications.

Yes, Nichrome 80 wire is renowned for its long lifespan in heating applications. One of the primary reasons for its durability is its resistance to oxidation, especially at high temperatures. When Nichrome is heated in an oxygen-rich environment, it forms a protective layer of chromium oxide on its surface. This thin layer shields the wire from further oxidation and degradation, allowing it to maintain its integrity and function over extended periods of frequent use. Additionally, Nichrome 80 does not undergo significant expansion or contraction with temperature changes, further enhancing its longevity. Its consistent performance, resistance to external factors, and ability to withstand numerous heating and cooling cycles make Nichrome 80 a preferred choice in many heating applications for its long-lasting properties.

Nichrome 80 wire is more commonly used as a heating element rather than in soldering applications directly. Here’s why:

Melting Point: While Nichrome 80 has a high melting point of around 1400°C (2552°F), soldering applications don’t necessarily require wire with such a high melting point. Instead, the wire itself acts as a heating element in many applications, not as a solder.

Poor Solderability: Nichrome is notoriously difficult to solder to because of its chromium content, which forms a passive oxide layer. This makes it challenging to get solder to adhere properly. If one intends to solder to Nichrome, the area usually needs to be mechanically cleaned and then immediately soldered using a specialised flux.

Resistivity: The primary advantage of Nichrome – its resistivity, which allows it to generate heat when current is passed through it – isn’t necessarily a beneficial property for soldering applications where you want efficient electrical connections without significant resistance.

For high-temperature soldering applications, it’s more common to use solders made from materials with higher melting points, like silver-based alloys. If Nichrome wire is involved in the soldering process, it’s often because the wire itself needs to be connected or integrated into a circuit, not because it’s acting as a solder. In such cases, mechanical connections like crimps or clamps, or alternative methods like spot welding, might be used instead of soldering.

Nichrome 80 wire, composed of approximately 80% nickel and 20% chromium, is well-regarded for its heat resistance and is commonly used in heating elements. While it boasts a melting point of around 1400°C (2552°F), in practical heating applications, it’s not operated anywhere near this limit. The maximum operating temperature for Nichrome 80 wire is typically lower, often in the range of 1100°C to 1200°C (2012°F to 2192°F). This ensures the wire’s longevity and safety in its applications. Operating it at temperatures closer to its melting point would reduce its lifespan and could compromise the reliability of the devices it’s used in. Moreover, consistently running the wire at its upper limits would accelerate the oxidation process, even with its inherent oxidation resistance, and could lead to premature failure. Therefore, while Nichrome 80 can withstand very high temperatures, it’s essential to use it within recommended operational limits to maintain its effectiveness and durability.

Nichrome 80 wire, a prominent alloy comprised of roughly 80% nickel and 20% chromium, possesses distinct properties that make it favorable for various applications, especially as a heating element. One such property is its non-magnetic nature. Unlike pure iron or certain types of steel, which are intrinsically magnetic, Nichrome 80 does not exhibit ferromagnetic behavior. This non-magnetic characteristic can be particularly advantageous in specific applications where magnetic interference might pose concerns, such as in certain electronic devices or sensors. Thus, the non-magnetic nature of Nichrome 80 wire further broadens its utility in a diverse range of technological and industrial contexts.

Check out our blog discussing ‘Now Available: Nichrome Wire‘. It will prove a useful read to help you to make an informed decision on which material would work best for you.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs, videos and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options