- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » How to Bend 40mm Steel Box Section: A Comprehensive Guide

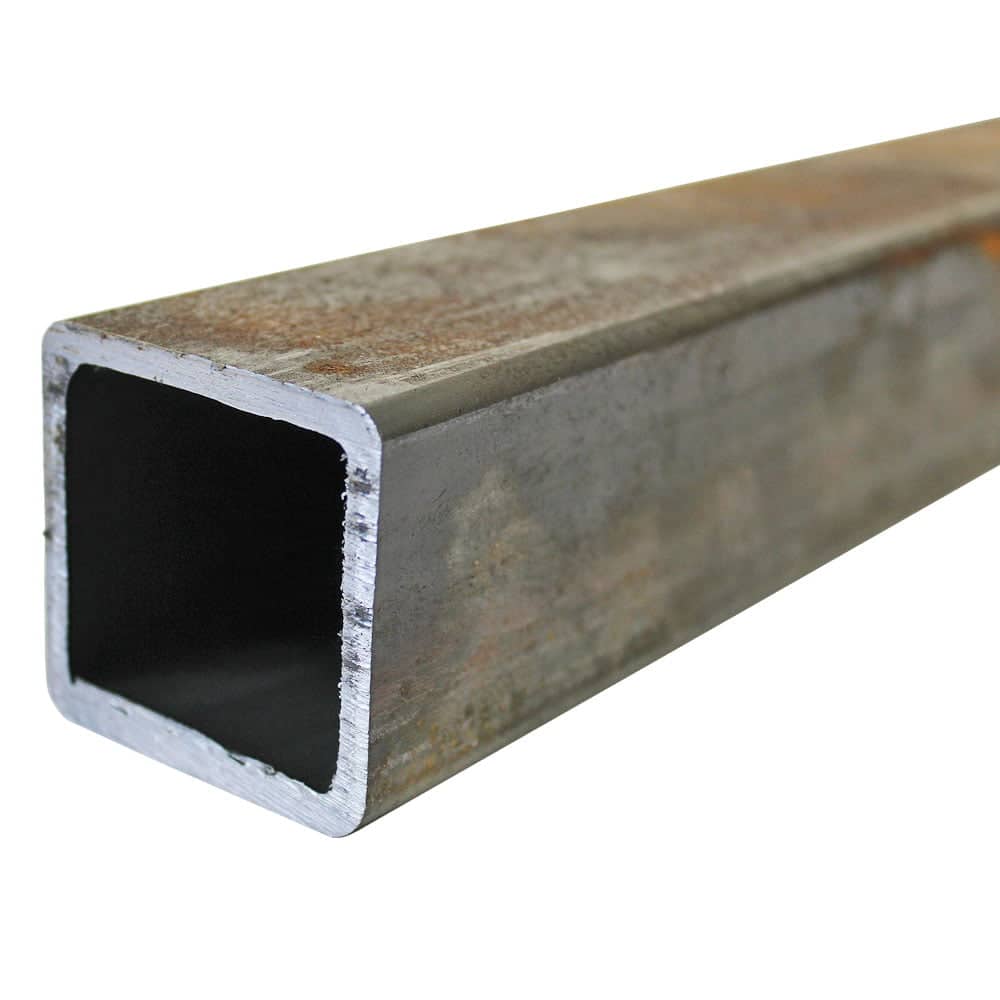

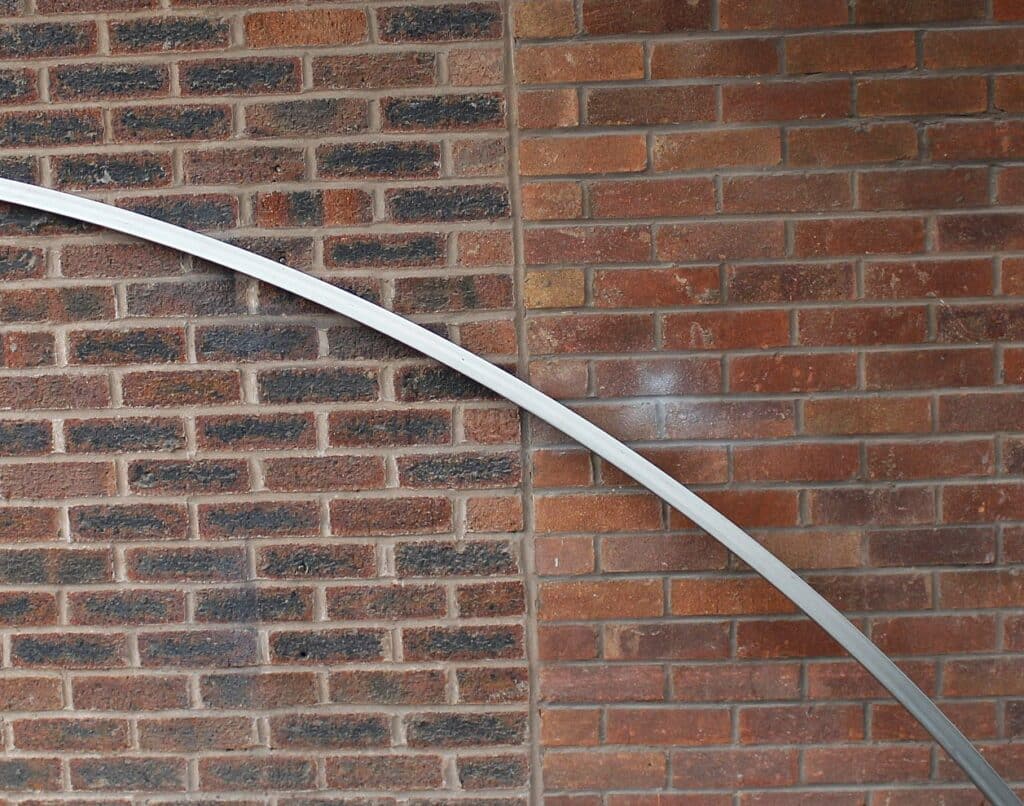

Steel box sections are a versatile and robust choice for a variety of applications, from construction to furniture design. However, bending steel box section requires careful planning, the right tools, and an understanding of the material’s properties to ensure a clean bend without compromising its integrity.

If you’re working with 40mm steel box section, this guide will take you through everything you need to know to achieve professional results.

At Speciality Metals, we supply 40mm mild steel box sections in varying wall thicknesses, as well as 316 grade stainless steel box sections, giving you a wide range of options for your project.

This article will provide tailored tips for bending each specification, ensuring you get the most out of your materials.

Bending steel box sections, especially those with a larger diameter like 40mm, is not without challenges. The process can lead to structural deformations such as wrinkling, buckling, or kinking if not executed correctly.

The key challenges include:

To successfully bend steel box sections, you need the right technique, tools, and an understanding of the specific material properties of your chosen section. We ourselves work with specialists when we have demanding bending requirements.

Before diving into specific techniques, it’s essential to understand a few fundamental aspects of bending steel box sections.

Cold Bending vs. Hot Bending

Bend Radius Considerations

Tool Selection

Cold Bending Mild Steel Box Sections

Materials: Mild steel box sections are relatively ductile, making them suitable for cold bending.

Tools: Use a hydraulic pipe bender or a section roller for clean bends.

Tips:

Hot Bending for Thick-Walled or Stainless Steel Sections

Materials: 316 grade stainless steel sections and thicker mild steel sections benefit from hot bending.

Tools: Use a propane torch or an induction heater for heating, followed by a hydraulic press or mandrel bender.

Tips:

Filling with Sand for Thin-Walled Sections

Materials: Thinner sections like 40 x 2.5mm or 40 x 1.5mm stainless steel.

Technique: Filling the tube with sand before bending prevents the walls from collapsing. Seal both ends with caps or plugs before starting.

Tools: A manual or hydraulic pipe bender can be used after filling the section.

The technique you choose depends largely on the material and thickness of the steel box section. Below is a breakdown of the best bending methods for the different specifications we offer at Speciality Metals:

| Specification | Recommended Bending Technique | Tips |

|---|---|---|

| 40 x 4mm Mild Steel | Cold bending with hydraulic pipe bender | Use a large former to prevent kinks; apply steady pressure. |

| 40 x 3mm Mild Steel | Cold or hot bending | For tight radii, consider heating the section for easier manipulation. |

| 40 x 2.5mm Mild Steel | Cold bending with sand filling | Fill with sand to avoid wall collapse; clamp securely during the process. |

| 40 x 20 x 1.5mm Stainless Steel | Hot bending with induction heating | Even heating is critical; use a mandrel bender for precise shaping. |

| 40 x 1.5mm Stainless Steel | Hot bending with sand filling | Thin walls require extra care; sand filling reduces the risk of deformation. |

Bent steel box sections are widely used in a variety of industries and DIY projects. Here are some common applications:

Construction

Automotive

Furniture Design

DIY Projects

Plan Ahead

Use Lubrication

Take Your Time

Practice on Scrap Pieces

Yes, thinner sections like 40 x 2.5mm mild steel can be bent using a manual bender. However, for thicker sections or stainless steel, professional tools are recommended.

Using a mandrel bender or filling the section with sand are effective methods to maintain the shape of the box section.

Heating is necessary for thicker sections or stainless steel, as it reduces the risk of cracking or deformation.

Yes, bent sections can be welded to other components. Ensure the edges are clean and free of debris before welding.

Bending 40mm steel box sections is a practical skill that opens up endless possibilities for both professional and DIY applications. By understanding the properties of your chosen material and using the right tools and techniques, you can achieve clean, professional bends that maintain the integrity of the box section.

At Speciality Metals, we provide a wide range of 40mm steel box sections in various specifications, including mild steel and 316-grade stainless steel. Whether you’re building a structural framework, designing furniture, or crafting a custom project, our high-quality materials are designed to meet your needs.

Explore our range today or contact our expert team for advice on working with steel box sections.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options