- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Exploring the Diverse Types of Aluminium Sheet Metal: A Speciality Metals Guide

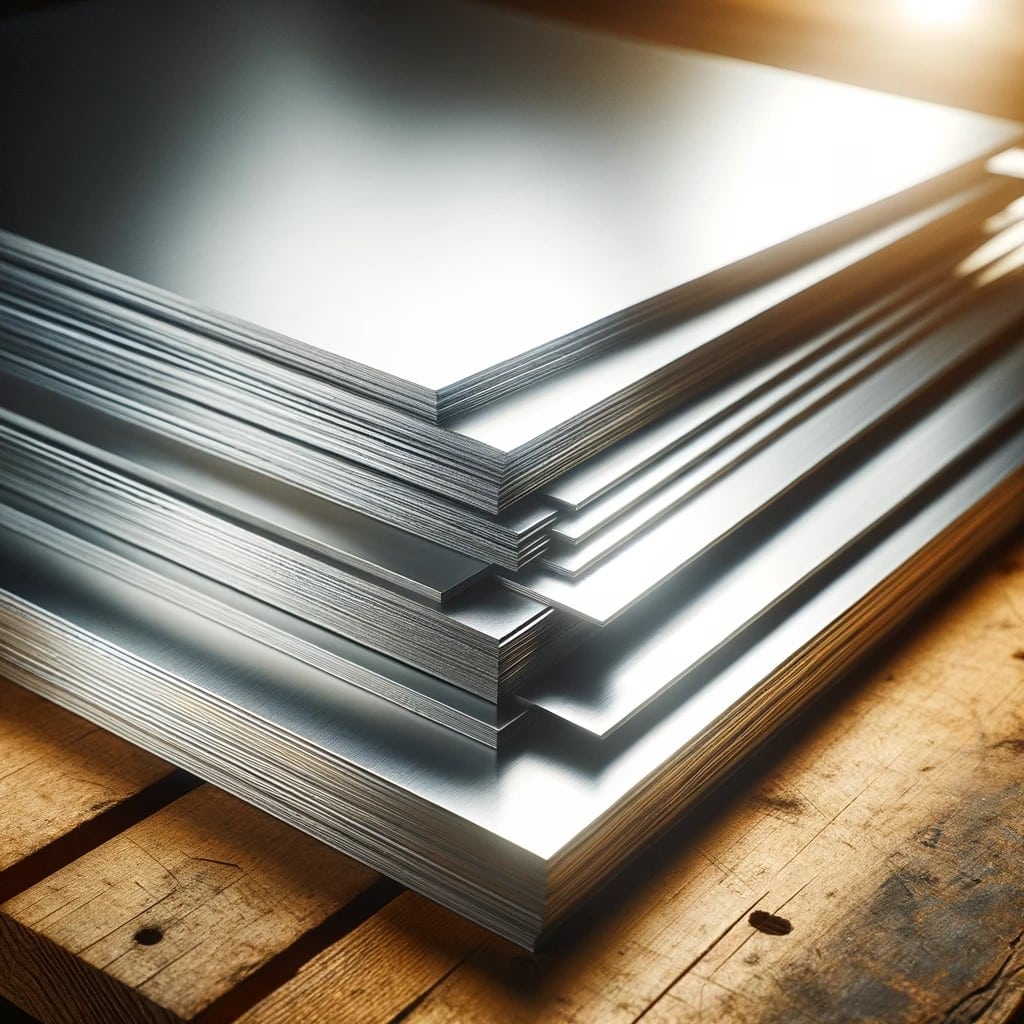

Renowned for its lightweight, yet remarkable strength, aluminium sheet metal has carved its niche in a plethora of applications, ranging from the sleek fuselages of aircraft to the robust bodies of automobiles, and even the delicate intricacies of consumer electronics.

Its unique blend of properties — corrosion resistance, malleability, and aesthetic appeal — makes it an indispensable material in both industrial and creative domains.

At Speciality Metals, we recognise the diverse applications and immense potential of aluminium sheet metal.

The purpose of this article is to explain the various types of aluminium sheet metal available, each tailored to the needs of specific projects. At Speciality Metals, we offer solutions for a wide variety of industries and applications. The guide will assist you in making informed decisions for your unique projects, whether you are an engineer, architect, or hobbyist.

Let’s go…

In addition to being lightweight and incredibly strong, aluminium is a silvery-white, soft metal. Since it is the third most abundant metal in the Earth’s crust, it is both accessible and cost-effective. Due to its corrosion resistance – caused by its protective oxide layer – aluminium is ideal for environments where resistance to the elements is paramount.

Aluminium is transformed into sheet metal through a series of processes including melting, casting, rolling, and annealing. In order to suit various applications, these processes are meticulously controlled to alter the metal’s properties, such as thickness, strength, and formability.

Aluminium sheet metal is ubiquitous across multiple industries. Its durability and ease of maintenance make it a popular choice for roofing, siding, and window frames in the construction industry. The lightweight nature of this material contributes to improved fuel efficiency and reduced emissions in the automotive industry. Aluminium sheet metal plays a crucial role in aircraft design because of its high strength-to-weight ratio. Moreover, its non-toxic properties make it suitable for food packaging and kitchen utensils.

Our aluminium sheet metal is available in various grades and finishes, each serving a different market. The 1100 series is excellent for its workability and moderate strength, while the 5000 and 6000 series are known for their superior corrosion resistance and durability.

Selecting the right type of aluminium sheet metal for a project is a nuanced decision that hinges on understanding various material properties and how they align with the project’s requirements.

We emphasise considering several key factors to ensure you make the most suitable choice for your needs:

Strength: The strength of aluminium sheet metal varies significantly across different grades. In structural applications, such as aerospace or automotive components, high-strength grades like the 7000 series are ideal. In less demanding applications, such as decorative trims, a lower-strength grade, such as the 3000 series, may be sufficient.

Formability: In complex applications, aluminum’s ability to be shaped is crucial. For intricate designs and detailed work, grades like 1100 are known for their excellent formability.

Corrosion Resistance: Although aluminium naturally resists corrosion, certain environments or applications may require enhanced protection. 5000-series grades provide superior corrosion resistance and are ideal for marine or chemical environments.

Specific Application Requirements: Each project has unique needs. Certain aluminum grades would be more suitable than others if thermal conductivity is required, as in heat exchangers. The 1000 series is also a good choice for electrical applications due to its purity.

Aesthetic Considerations: In addition, aluminium sheet metal comes in a variety of finishes and appearances. Consider grades that can retain their appearance over time if aesthetics are important, such as in architectural applications.

Cost-Effectiveness: Budget constraints are always a concern. Making an economical choice without compromising quality requires weighing the costs and benefits of each grade.

We take great pride in offering a wide and versatile range of aluminium sheet metal products. Our product selection includes several grades, each tailored to meet a client’s specific needs. Our range ensures that you have access to the best solution for your project, whether it is the highly formable 1100 series or the strong and durable 7000 series.

Quality is at the forefront of our offerings. The sheets are manufactured and tested to meet stringent industry standards, ensuring reliability and performance. Our commitment to quality ensures that our products are durable and efficient.

In addition to providing custom solutions, we also understand that every project is unique. Precision cutting to specific dimensions, various finishes and treatments, and expert advice are just some of the services we offer. No matter if you are looking for a standard sheet for general use or a custom-designed piece for a specific application, Speciality Metals can help.

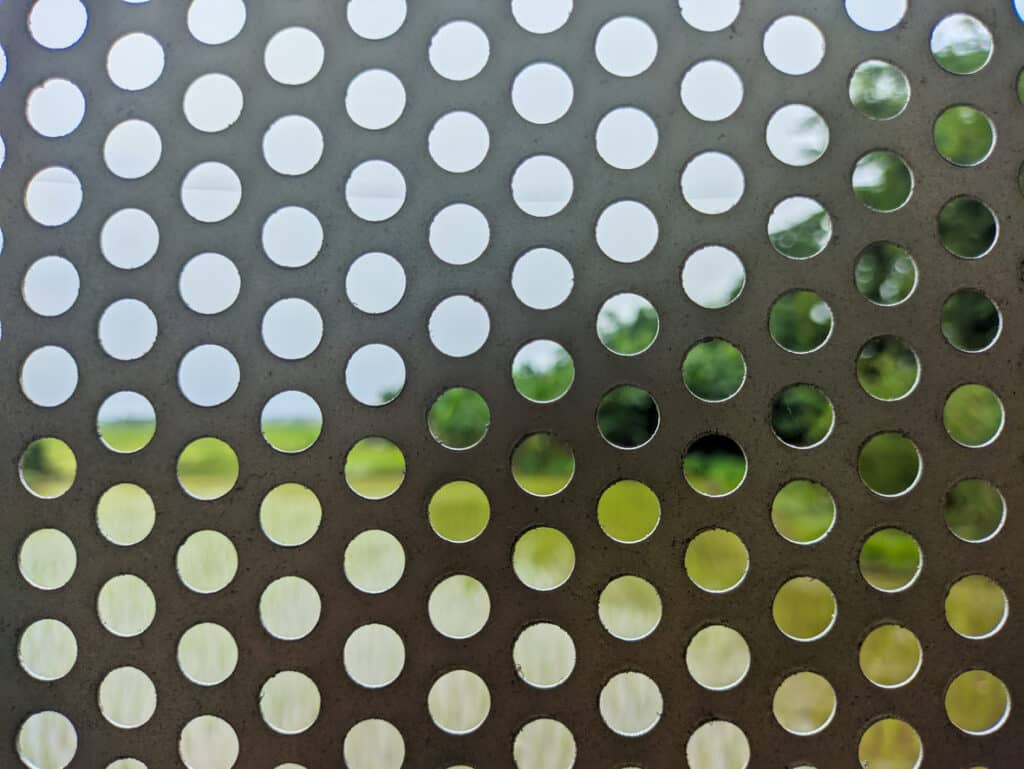

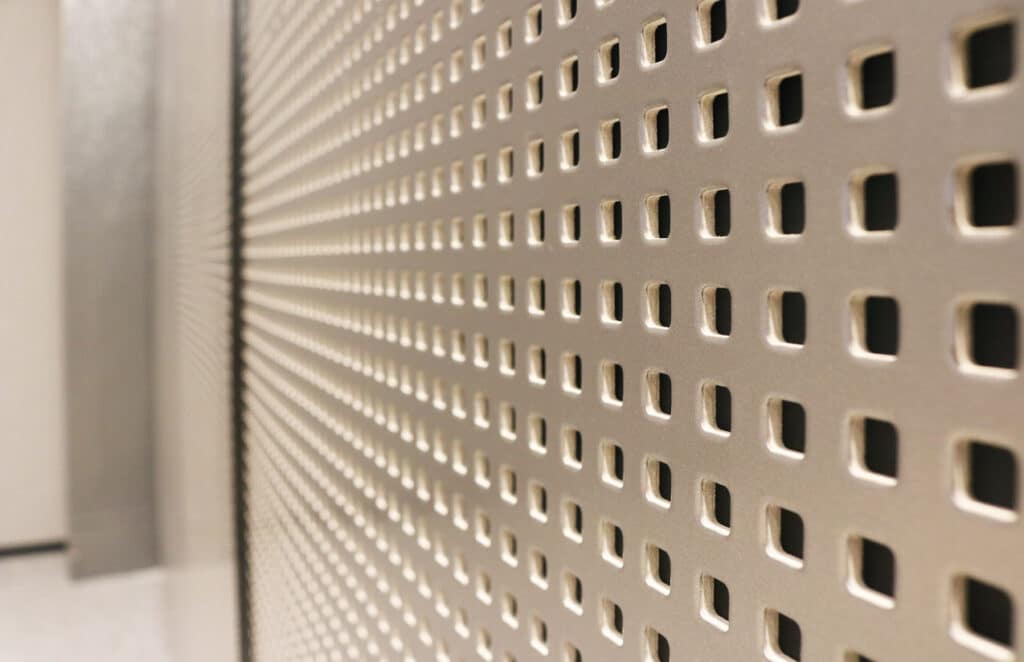

Speciality Metals offers a wide array of aluminium types, each suited for specific sheet metal applications. Here’s a comprehensive list of the types of aluminium available for sheet metal:

Each type of aluminium sheet metal comes with distinct properties that make it suitable for specific uses, ensuring that no matter the project, there is an aluminium grade that meets the requirements.

Aluminium sheet metal, with its wide range of grades and unique properties, stands as a versatile and essential material in various industries.

Selecting the right aluminium sheet metal for your specific application requires an understanding of these differences, a decision that greatly impacts your project’s success and longevity.

The Speciality Metals team is committed to providing not only a diverse range of high-quality aluminium sheet metals, but also guiding our clients in choosing the right type. With our expertise and custom solutions, we ensure you have access to the best materials and support for your project.

You are invited to explore the vast possibilities of our aluminium sheet metal range and to contact Speciality Metals for any guidance, custom requirements, or queries.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options