- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Which Corrosion-Resistant Metals Are Best for Corrosive Environments?

When working with metal in marine, industrial, and outdoor environments, corrosion is a serious concern. Choosing the right corrosion-resistant metals can significantly impact the longevity, strength, and maintenance requirements of your project.

At Speciality Metals, we supply a range of metals designed to withstand harsh conditions, including stainless steel, aluminium, and galvanised steel. Whether you’re building for marine applications, chemical processing, or general outdoor use, this guide will help you understand which metals offer the best durability.

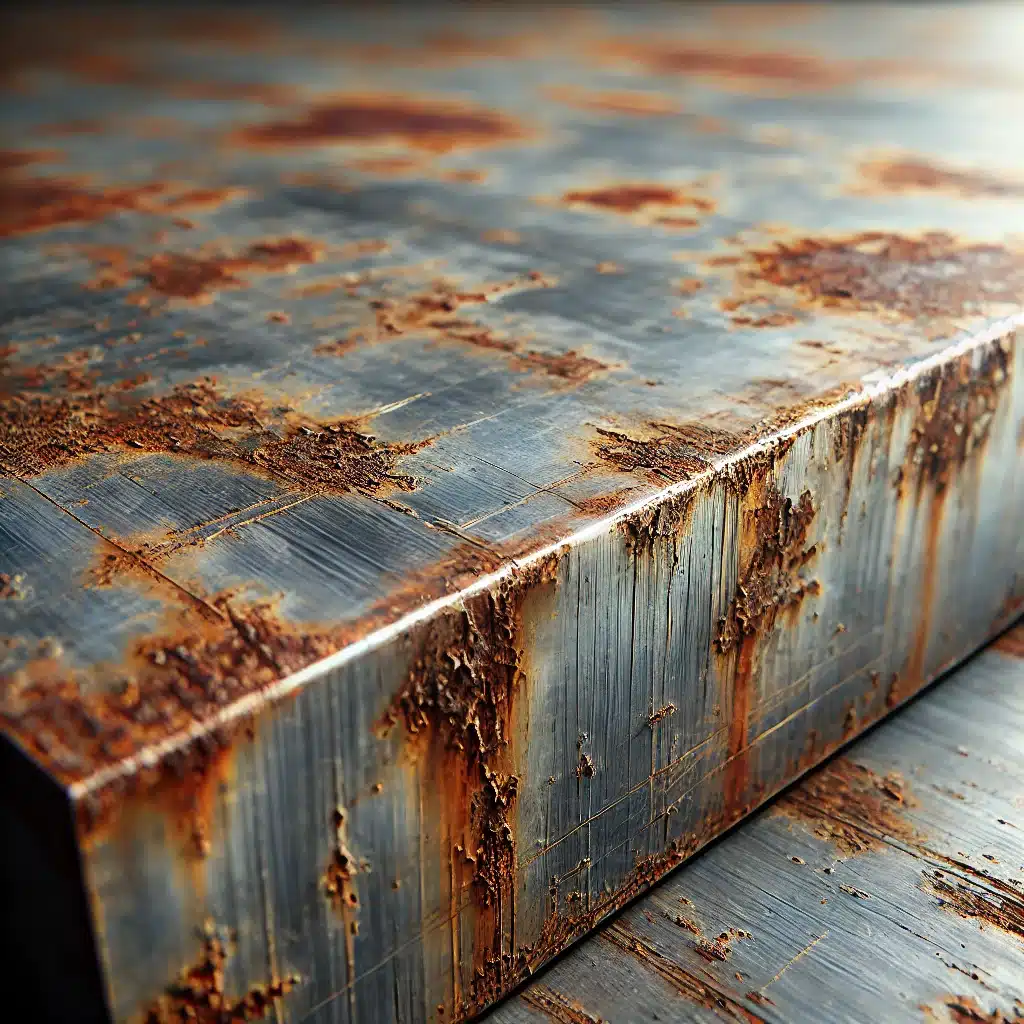

Corrosion occurs when metal reacts with oxygen, moisture, or chemicals in its environment, leading to rust, pitting, or degradation. There are different types of corrosion, including:

✔ Oxidation: The most common type, where metals like steel develop rust in the presence of water and oxygen.

✔ Galvanic Corrosion: Occurs when different metals come into contact with each other in an electrolyte (e.g., seawater).

✔ Pitting Corrosion: Small, localised holes form in a metal’s surface, common in stainless steel and aluminium in aggressive environments.

✔ Crevice Corrosion: Happens when moisture gets trapped in tight spaces, leading to localised breakdown.

Choosing the right metal and applying protective coatings can significantly extend the lifespan of your structure or component.

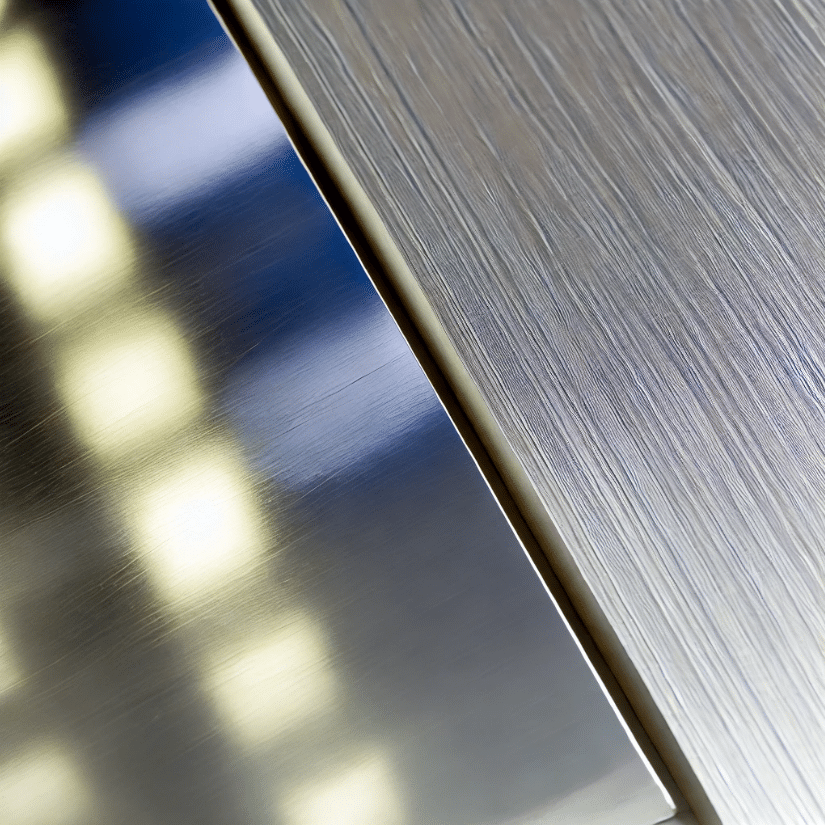

Stainless steel is one of the most widely used corrosion-resistant metals due to its chromium content. The chromium forms a passive oxide layer, protecting the metal from rust.

| Stainless Steel Grade | Best for | Corrosion Resistance | Example from Speciality Metals |

|---|---|---|---|

| 304 Stainless Steel | Indoor and mild outdoor environments | High | Stainless Steel Sheet, Flat Bar, Box Section |

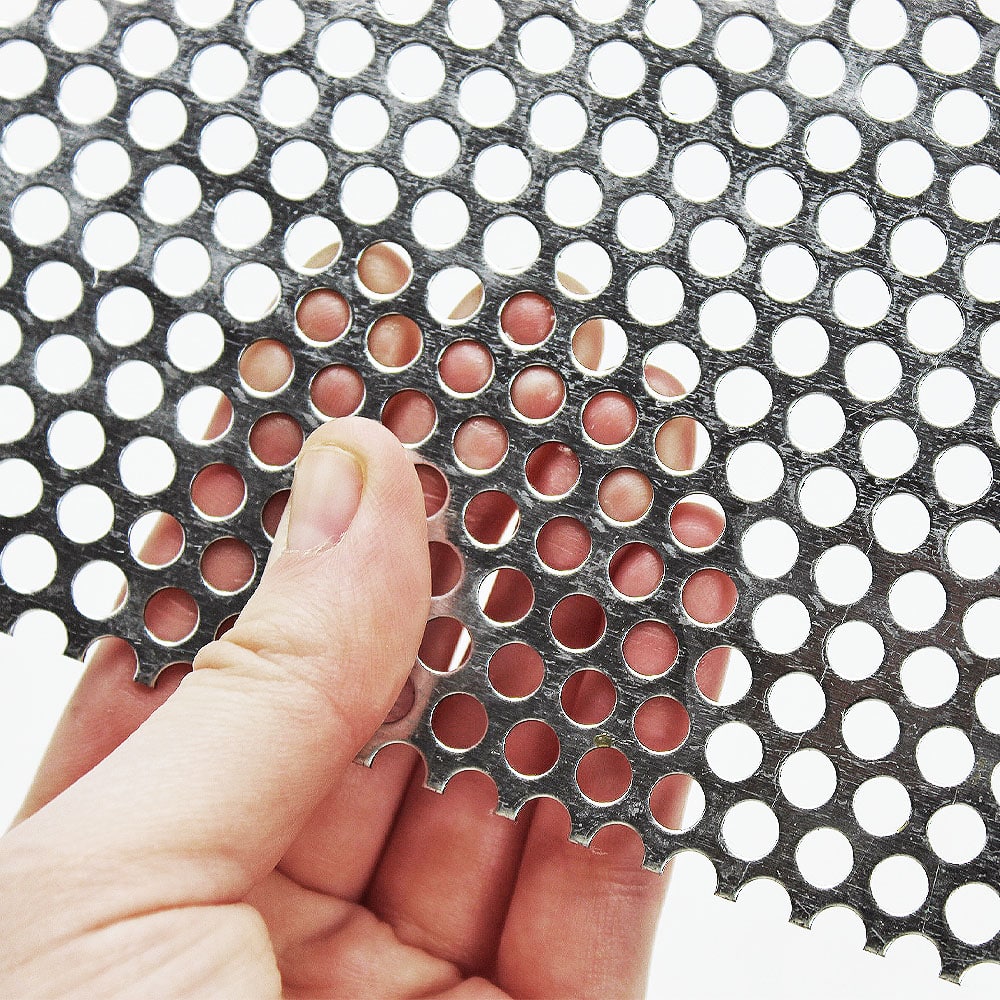

| 316 Stainless Steel | Marine and chemical environments | Very High | Stainless Steel Round Tube, Perforated Mesh |

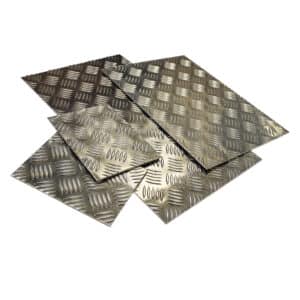

| 430 Stainless Steel | Decorative, low-moisture areas | Moderate | Stainless Steel Checker Plate |

💡 Example from Speciality Metals:

If you need a marine-grade material for boat fittings or chemical processing, our 316 Stainless Steel Round Tube is a durable, rust-resistant solution.

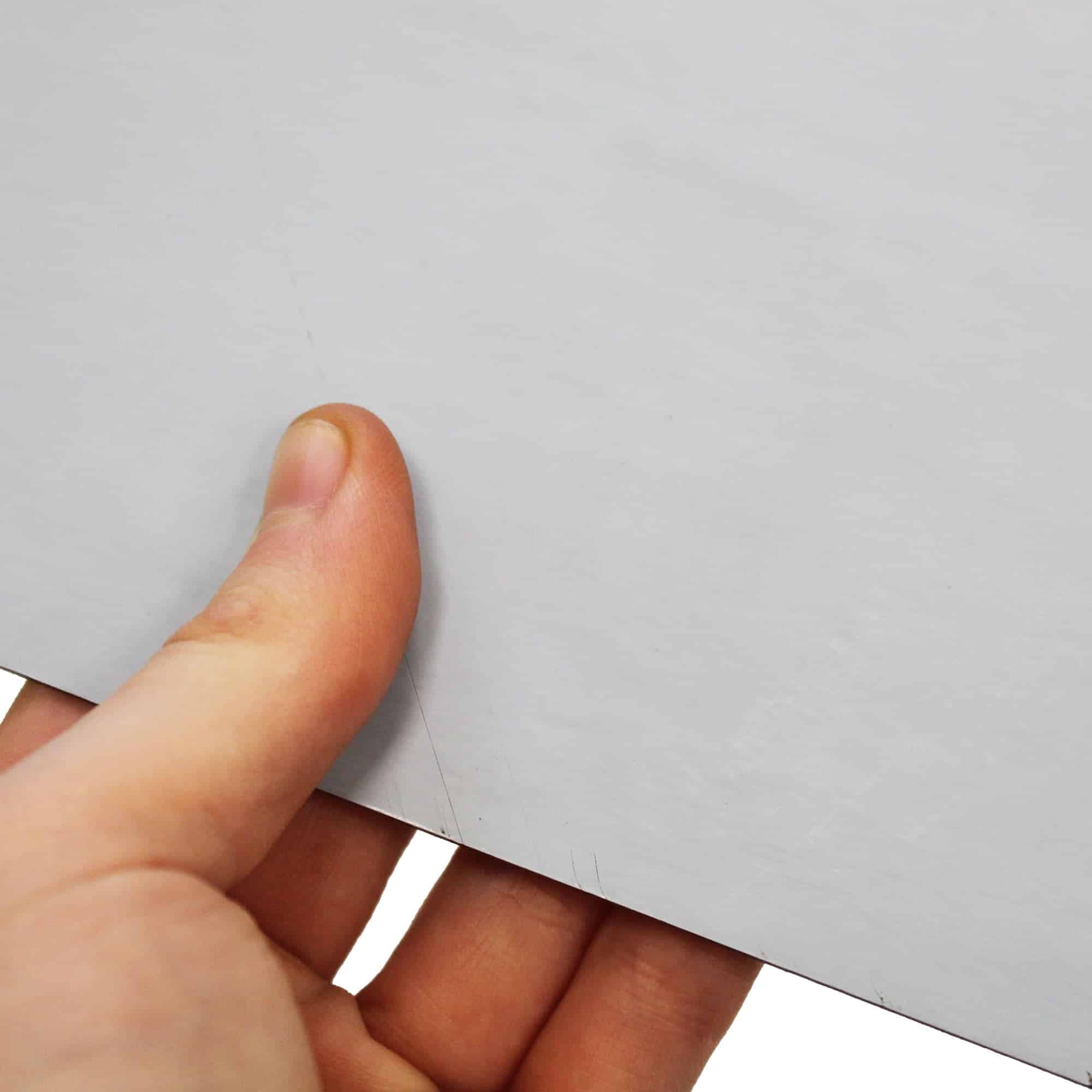

Aluminium develops a protective oxide layer that resists corrosion. It’s particularly useful for outdoor applications, roofing, and electrical components.

✔ Key Benefits:

| Aluminium Type | Best for | Example from Speciality Metals |

|---|---|---|

| 1050 Aluminium | Signage, indoor applications | Aluminium Sheet Metal |

| 5083 Aluminium | Marine and industrial use | Aluminium U Channel |

| 6061 Aluminium | Structural applications | Aluminium Box Section |

💡 Example from Speciality Metals:

If you’re working on a marine or offshore project, our 5083 Aluminium Sheet Metal offers exceptional saltwater resistance.

Copper is highly resistant to corrosion, particularly in moist environments. Over time, it forms a green patina that acts as a protective barrier against further corrosion.

✔ Key Benefits:

| Best Uses | Example from Speciality Metals |

|---|---|

| Electrical wiring & roofing | Copper Sheet Metal |

| Decorative and artistic designs | Copper Round Bar |

| Water piping & plumbing | Copper Tube |

💡 Example from Speciality Metals:

For roofing applications requiring corrosion resistance and aesthetic appeal, our Copper Sheet Metal is a premium choice.

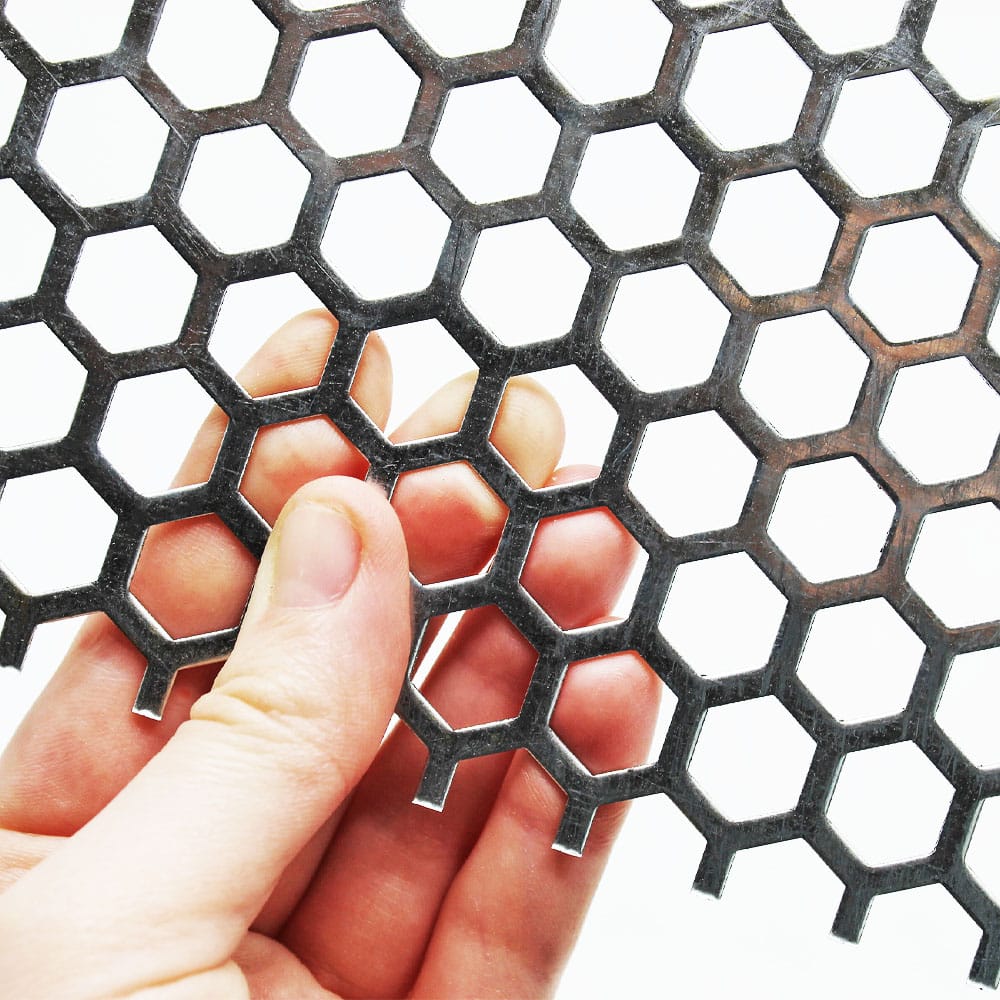

Galvanised steel is regular steel coated in a protective zinc layer, making it highly resistant to moisture, humidity, and outdoor conditions.

✔ Key Benefits:

| Best Uses | Example from Speciality Metals |

|---|---|

| Outdoor fencing & gates | Galvanised Steel Sheet |

| Structural frameworks | Galvanised Steel Box Section |

| Ventilation covers & industrial grilles | Galvanised Perforated Mesh |

💡 Example from Speciality Metals:

For construction projects needing rust protection, our Galvanised Steel Sheet Metal offers affordable, long-lasting durability.

Titanium is used in high-performance applications like aerospace, medical implants, and marine engineering due to its exceptional resistance to corrosion and extreme temperatures.

✔ Key Benefits:

💡 Example from Speciality Metals:

While titanium is not a standard product at Speciality Metals, alternatives like 316 Stainless Steel provide a more cost-effective solution with similar corrosion resistance.

| Metal Type | Corrosion Resistance | Best Use Cases | Cost |

|---|---|---|---|

| Stainless Steel (316) | Very High | Marine, food processing, chemical industries | £££ |

| Aluminium (5083) | High | Marine, transport, industrial | ££ |

| Copper | High | Electrical, plumbing, roofing | £££ |

| Galvanised Steel | Moderate to High | Outdoor construction, ventilation | £ |

| Titanium | Very High | Aerospace, medical, extreme environments | ££££ |

Even the most corrosion-resistant metals can benefit from additional protection and maintenance:

✅ Apply Protective Coatings: Use powder coating, anodising, or paint to extend longevity.

✅ Regular Cleaning: Stainless steel and aluminium surfaces should be cleaned to prevent contamination.

✅ Use Corrosion Inhibitors: Industrial projects can benefit from chemical treatments to slow oxidation.

✅ Avoid Mixed Metals in Contact: Prevent galvanic corrosion by using the same metal types together.

💡 Example from Speciality Metals:

If you’re building outdoor railings or gates, choosing galvanised steel and applying powder coating can provide maximum durability.

Selecting the right corrosion-resistant metal depends on environmental exposure, budget, and required durability.

✔ For marine environments – 316 Stainless Steel or 5083 Aluminium

✔ For industrial & chemical exposure – Stainless Steel 316

✔ For affordable outdoor durability – Galvanised Steel

✔ For electrical and decorative use – Copper

At Speciality Metals, we stock a variety of corrosion-resistant metals, including stainless steel, aluminium, galvanised steel, and copper.

💡 Need expert advice? Browse our collection at www.smetals.co.uk or contact our team for guidance on selecting the best material for your project.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options