- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » The Melting Points of Different Metals: A Comprehensive Guide

As we all know, metals play an essential role in countless industries, from construction and manufacturing to automotive and aerospace applications. One of the most critical properties to consider when selecting a metal is its melting point.

This key characteristic determines how a metal behaves under high temperatures, affecting processes such as welding, forging, machining, and overall usability.

At Speciality Metals, we offer an extensive range of high-quality metal products, including aluminium, mild steel, stainless steel, and galvanised steel.

Understanding the melting points of these materials is crucial when choosing the right metal for your project. Whether you’re fabricating custom parts or repairing heavy machinery, knowing the thermal properties of metals can save time, effort, and cost.

In this comprehensive guide, we’ll explore the melting points of different metals and how these properties influence their applications. We’ll also provide a detailed chart for quick reference and a closer look at the specific metals we offer, breaking down their unique properties and uses.

Below is a detailed reference chart listing the melting points of common metals, both ferrous and non-ferrous, as well as precious metals. Use this guide to identify which metals suit your specific project requirements, including those available in the Speciality Metals range.

| Metal | Melting Point (°C) | Melting Point (°F) | Notes / Applications |

|---|---|---|---|

| Aluminium | 660°C | 1,220°F | Lightweight, corrosion-resistant; used in aerospace, automotive, and DIY projects (offered at Speciality Metals). |

| Brass | 930°C | 1,710°F | Decorative, musical instruments, and plumbing components. |

| Chromium | 1,860°C | 3,380°F | Corrosion-resistant; used as an alloying element in stainless steel. |

| Copper | 1,084°C | 1,983°F | Excellent conductivity; used in electrical wiring, roofing, and plumbing. |

| Gold | 1,063°C | 1,945°F | High value, used in electronics, jewellery, and investment. |

| Cast Iron | 1,204°C | 2,200°F | Durable and brittle; used in machinery, pipes, and automotive components. |

| Lead | 328°C | 622°F | Low melting point; used in batteries, radiation shielding, and roofing. |

| Nickel | 1,453°C | 2,647°F | Corrosion-resistant; used in batteries, alloys, and industrial applications. |

| Platinum | 1,770°C | 3,218°F | High-value, corrosion-resistant; used in catalytic converters and jewellery. |

| Silver | 961°C | 1,762°F | Conductive; used in jewellery, electronics, and mirrors. |

| Carbon Steel | 1,425–1,540°C | 2,597–2,800°F | Strong and versatile; used in construction, automotive, and industrial equipment (offered at Speciality Metals). |

| Stainless Steel | 1,375–1,530°C | 2,500–2,785°F | Corrosion-resistant; used in kitchenware, architecture, and marine applications (offered at Speciality Metals). |

| Titanium | 1,670°C | 3,038°F | Lightweight and strong; used in aerospace, medical implants, and industrial applications. |

| Tungsten | 3,400°C | 6,152°F | Extremely high melting point; used in filaments, tools, and high-temperature applications. |

| Zinc | 420°C | 787°F | Used in galvanising to protect steel (e.g., galvanised steel sheets at Speciality Metals). |

The melting point of a metal refers to the temperature at which it transitions from a solid to a liquid state. This property is crucial because it influences the metal’s behaviour in various applications.

Why It’s Important:

Below is a quick-reference chart that provides the melting points of common metals in degrees Celsius and Fahrenheit. Each metal corresponds to the products we offer at Speciality Metals:

| Metal | Melting Point (°C) | Melting Point (°F) | Speciality Metals Products |

|---|---|---|---|

| Aluminium | 660°C | 1,220°F | Aluminium sheets, round tubes, U channels, T sections |

| Mild Steel | 1,370°C | 2,500°F | Mild steel sheets, round tubes, square hollow sections |

| Stainless Steel | 1,400–1,530°C | 2,550–2,790°F | Stainless steel sheets, round tubes, flat bars, U channels |

| Copper | 1,085°C | 1,984°F | Copper sheets and round bars |

| Galvanised Steel | ~1,370°C | ~2,500°F | Galvanised sheets, angle bars, and mesh |

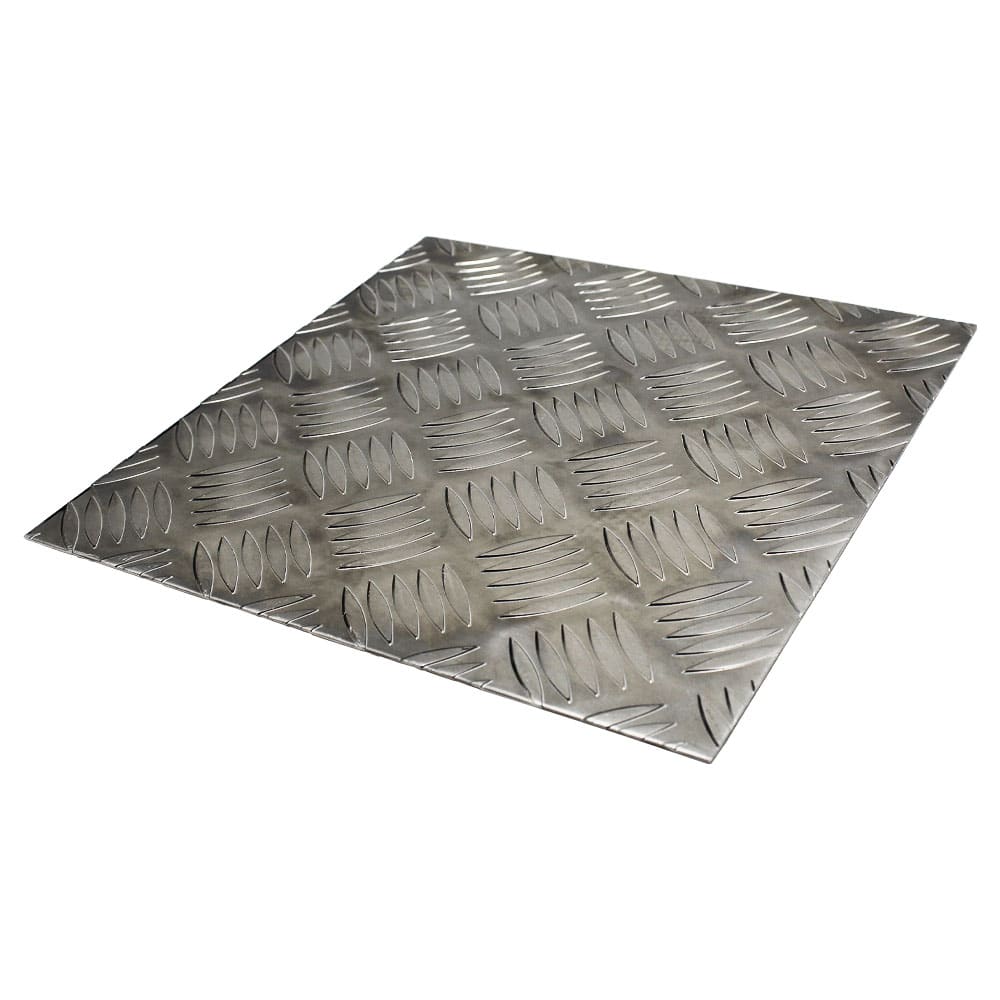

Aluminium is one of the most versatile metals, with a melting point of 660°C (1,220°F). Its lightweight nature, corrosion resistance, and excellent thermal conductivity make it ideal for a range of uses.

Applications:

Speciality Metals’ Aluminium Products:

For welding or machining aluminium, its relatively low melting point makes it easier to work with, but care must be taken to avoid overheating.

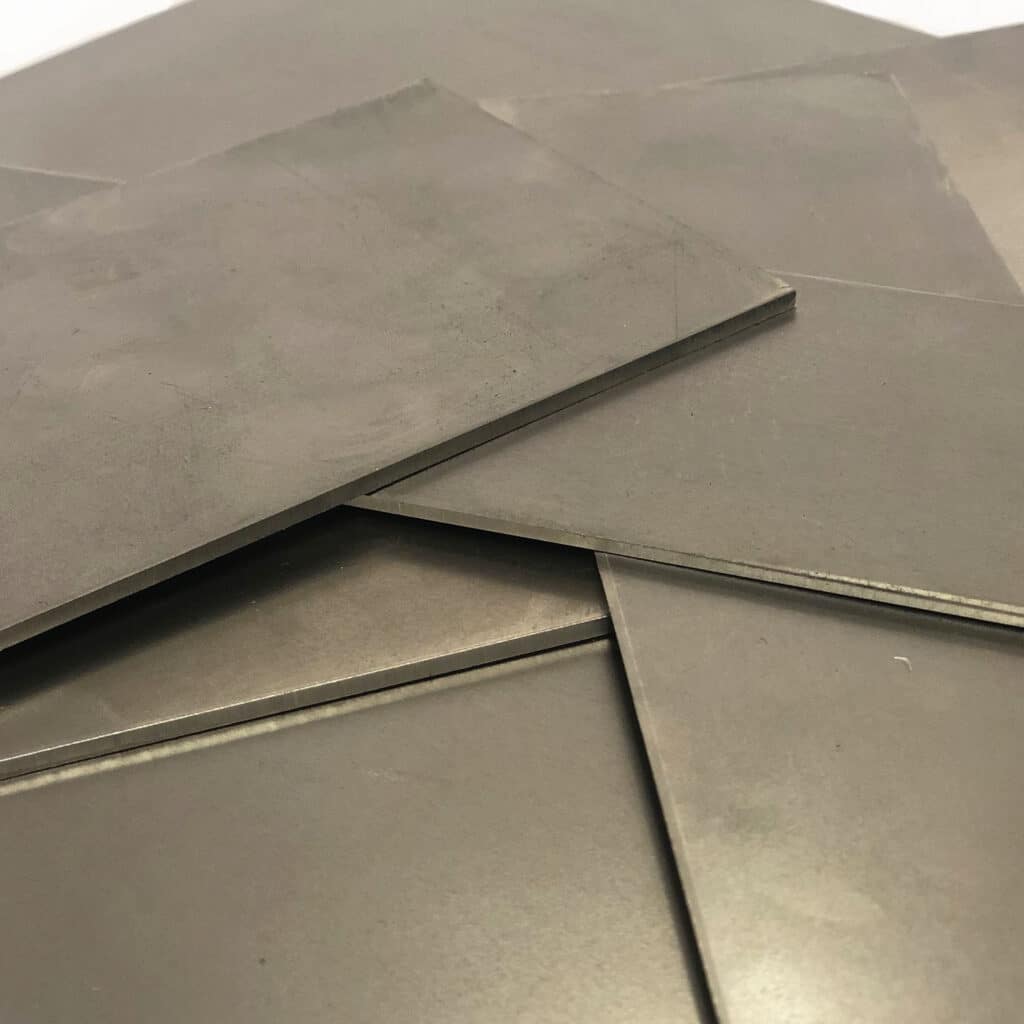

Mild steel, with a melting point of 1,370°C (2,500°F), is a staple in construction and industrial applications due to its affordability and malleability.

Applications:

Speciality Metals’ Mild Steel Products:

Mild steel’s higher melting point makes it more resistant to deformation under heat, but it requires specialised equipment for machining and welding.

Stainless steel has a melting range between 1,400°C and 1,530°C (2,550°F to 2,790°F). Its exceptional corrosion resistance makes it a popular choice for both indoor and outdoor applications.

Applications:

Speciality Metals’ Stainless Steel Products:

Working with stainless steel requires consideration of its high melting point, which makes it challenging to weld and cut without specialised tools.

Galvanised steel has a base material of mild steel with a zinc coating to enhance its corrosion resistance. Its melting point is similar to mild steel, around 1,370°C (2,500°F), but the zinc layer melts at approximately 419°C (786°F).

Applications:

Speciality Metals’ Galvanised Steel Products:

Galvanised steel combines the strength of mild steel with the added durability of zinc coating, making it a versatile choice for outdoor projects.

1. Why does the melting point matter?

The melting point determines the metal’s suitability for high-temperature applications, such as welding or industrial machinery.

2. Can I weld metals with different melting points?

Yes, but it requires careful preparation and the use of filler materials to manage the difference in melting points.

3. Which metal is best for outdoor use?

Stainless steel and galvanised steel are the best options due to their corrosion resistance.

4. How do I calculate the right metal for my project?

Consider factors like melting point, strength, weight, and corrosion resistance. Contact our team for expert guidance.

Understanding the melting points of different metals is essential for selecting the right material for your project. Whether you need aluminium for its lightweight properties, mild steel for its strength, or stainless steel for its corrosion resistance, each metal offers unique benefits tailored to specific applications.

At Speciality Metals, we offer a wide range of high-quality metal products, including sheets, tubes, and mesh, in aluminium, mild steel, and stainless steel. Our extensive range ensures that you’ll find the perfect metal for your next project, whether it’s industrial fabrication, DIY repairs, or architectural designs.

Explore our range today and feel free to contact our expert team for advice and guidance on selecting the ideal material for your needs.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options