- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

£19.99 – £36.99 inc VAT

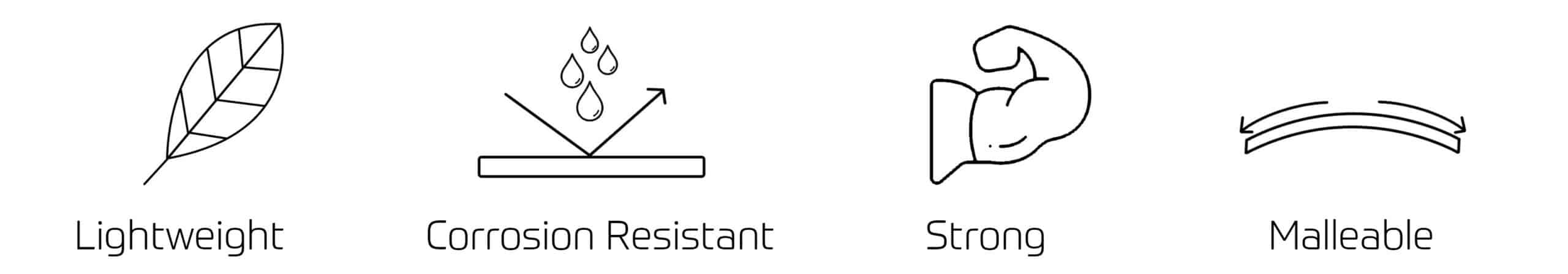

Are you in search of a reliable building material that has good hygiene properties? Look no further than the 8mm round aluminium perforated metal panel by Speciality Metals! Not only is this panel completely odorless, it’s also incredibly durable and lightweight making it easy to install. Plus, its excellent thermal and electrical conductivity ensures optimal temperature control and power distribution in your space. Don’t worry about corrosion, as this panel is also resistant to it. And if you need to manipulate the size or shape, it’s malleable for your convenience. Trust us, the 10mm pitch x 1.5mm thickness of this aluminium perforated metal panel will be the perfect addition to your construction needs.

Top quality aluminium perforated sheet supplied straight from Warrington, UK.

We offer an innovative solution to your construction needs with our 8mm round aluminium perforated metal panel. These panels have a 10mm pitch and 1.5mm thickness, which not only make them visually appealing but also make them highly functional, boasting excellent hygiene properties. An odorless environment ensures a sterile and clean working environment. Due to its lightweight composition and durability, it is easy to install and lasts for a long time. It dissipates heat efficiently while remaining energy-efficient since it conducts thermal and electrical currents well. As a corrosion-resistant and malleable material, it is suitable for a wide range of construction projects, ensuring a long-lasting and cost-effective solution. Your designs will be enhanced by aluminium perforated metal panel’s superior characteristics.

Specifications:

We also are the exact suppliers for you because:

Furthermore we stock a vast range of plain sheet metal options that compliment our mesh range perfectly.

The perforations in a mesh can significantly affect its radiofrequency (RF) transparency. Here’s how:

Size of Perforations Relative to Wavelength: The most critical factor determining RF transparency is the size of the perforations relative to the wavelength of the RF signal. If the perforation size is much larger than the wavelength, the RF signals will pass through with ease. Conversely, if the perforation size is smaller than the RF wavelength, the mesh will act as a barrier and reflect the RF signals, reducing transparency.

Shape of Perforations: The shape of the perforations can also play a role. For example, square or rectangular perforations might interact differently with RF waves compared to round or hexagonal shapes, especially when polarisation is considered.

Material Conductivity: The material of the mesh, such as aluminum, is conductive. A conductive grid or mesh can create a Faraday cage effect, which shields the enclosed space from external electromagnetic fields. The efficiency of this shielding is influenced by the size and spacing of the perforations.

Thickness of the Material: The thickness of the material can also impact RF transparency. A thicker material with the same perforation size will generally provide more attenuation to RF signals than a thinner one.

Spacing and Density of Perforations: A densely perforated mesh (more perforations per unit area) tends to be more transparent to RF signals than a mesh with fewer perforations, assuming the perforation size remains the same.

Incident Angle of RF Signals: The angle at which the RF signals hit the mesh can affect their transmission. Signals that hit the mesh at oblique angles might experience different levels of attenuation than those coming head-on.

Yes, aluminum perforated mesh can act as an effective barrier against pests, depending on the size and design of the perforations. Aluminum, being a robust and durable material, resists corrosion and damage that can be caused by external elements, ensuring longevity in its protective role. The key to using aluminum perforated mesh as a pest barrier is in selecting the appropriate size of perforations. Smaller pests, like mosquitoes and gnats, require tiny perforations to prevent entry, while larger pests like rodents will be deterred by larger perforations. Beyond its efficacy against pests, aluminum mesh offers the added advantage of allowing airflow and light, ensuring that while pests are kept out, the comfort and aesthetics of the living or working space are maintained. Additionally, being resistant to rust and requiring minimal maintenance, aluminum mesh provides a long-lasting and cost-effective solution for pest control. However, for optimum results, it’s crucial to ensure that the mesh is properly installed without gaps or openings where pests might squeeze through.

The lifespan of aluminum perforated mesh in outdoor environments is influenced by several factors:

Inherent Corrosion Resistance: Aluminum naturally forms a thin oxide layer on its surface when exposed to air. This oxide layer acts as a protective barrier against corrosion, making aluminum relatively durable in many outdoor environments.

Alloy Type: Not all aluminum alloys have the same resistance to corrosion. Some, like the 3003 and 5052 series, are more corrosion-resistant than others. The choice of alloy can impact the longevity of the mesh in specific environments.

Surface Treatments: Aluminum perforated mesh can undergo treatments like anodizing, powder coating or painting, which can enhance its corrosion resistance and aesthetic appearance. These treatments can significantly extend the lifespan of the mesh, especially in aggressive environments like coastal areas with salt spray.

Environmental Factors: The local environment plays a significant role in determining the lifespan of outdoor installations. Coastal areas with salt in the air, industrial areas with high pollution levels and regions with acidic rain can reduce the lifespan of aluminum products.

Physical Damage: Although aluminum is relatively durable, physical damage from impacts, abrasion or excessive bending can compromise its protective oxide layer, potentially leading to localised corrosion.

Maintenance: Regular cleaning and maintenance can extend the lifespan of aluminum perforated mesh. Removing accumulated dirt, debris and corrosive substances helps preserve the material’s integrity.

Yes, aluminum perforated sheet can be employed in flooring applications, offering both functional and aesthetic benefits. Due to aluminum’s inherent strength-to-weight ratio, it can provide the necessary sturdiness for flooring while remaining relatively lightweight. The perforations in the sheet can offer improved traction, making it particularly useful in settings where slip resistance is crucial, such as industrial platforms, walkways or stairs. Furthermore, these perforations facilitate drainage, making the flooring ideal for environments exposed to water or other fluids. The natural corrosion resistance of aluminum, combined with its ability to form a protective oxide layer, means that it can withstand the challenges of outdoor environments or areas exposed to chemicals. Additionally, with surface treatments or finishes, the wear resistance and aesthetic appeal of aluminum flooring can be enhanced. However, when using aluminum perforated sheets for flooring, it’s essential to select the appropriate thickness, alloy and perforation size to ensure safety, durability and desired performance in the specific application.

Check out our blog discussing What is Perforated Mesh. It will prove a useful read to help you to make an informed decision on which material would work best for you.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs, videos and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options