- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

£19.99 – £36.00 inc VAT

This website is secured:

£ MULTIBUY SAVINGS – Order 3 For 10% Off

✔ Specialists In Rapid Shipments Of Any Size

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

@ ☏ Bespoke Cuts & Larger Sheets Available

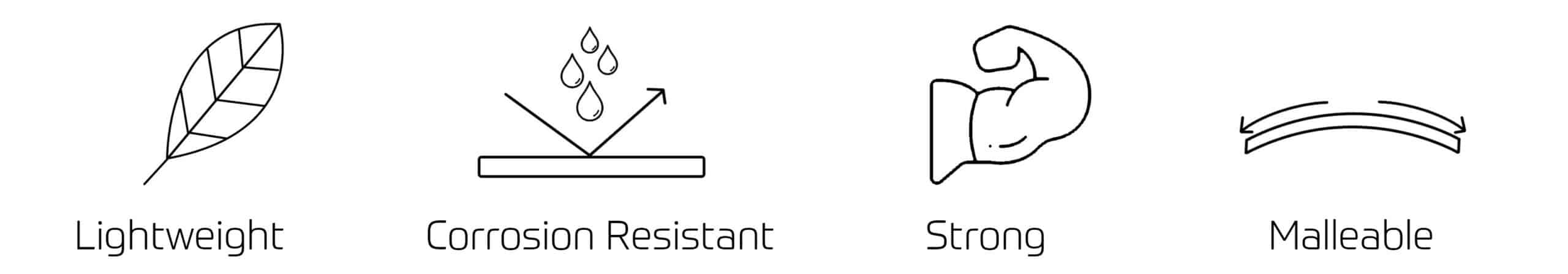

Have you heard about the 5mm Round Aluminium Perforated Panel by Speciality Metals? This panel is not only visually appealing but has many great features too. It boasts of hygiene properties, making it a safer option for projects that require optimal cleanliness. It’s also odorless, which is a big plus! This panel is very durable, and it can withstand harsh weather conditions. The best part is it’s lightweight, making it easy to handle and install. It’s also a good conductor of thermal and electricity, so you don’t have to worry about electrical leaks. Plus, it’s corrosion-resistant and malleable, making it a versatile option for all your projects. So, if you’re looking for a reliable and durable aluminum perforated panel, you can’t go wrong with the 5mm Round Aluminium Perforated Panel by Speciality Metals.

Top quality aluminium perforated panel supplied straight from Warrington, UK.

With an 8mm pitch and 1.25mm thickness, Speciality Metals offers a 5mm Round Aluminium Perforated Panel. As a result, this panel is ideal for using in a wide variety of applications due to its excellent hygiene properties. It features odorlessness, durability and lightweight properties, making it easy to handle. Furthermore, it is a good conductor of thermal and electrical energy, which makes it a very versatile material. Panels made of this material are corrosion resistant, meaning they will last for a long time in any environment. A further feature of this panel is its malleability, which allows it to be customised for specific applications. If you are searching for a high-quality aluminium perforated panel, this panel is a reliable and efficient choice.

Specifications:

We also are the exact suppliers for you because:

Furthermore we stock a vast range of plain sheet metal options that compliment our mesh range perfectly.

Yes, there are health and safety guidelines to consider when working with aluminum perforated metal. Following these guidelines ensures the safety of individuals and prevents potential health risks or injuries. Here are some key guidelines:

Personal Protective Equipment (PPE):

Handling and Storage:

Machining and Cutting:

Chemical Exposure:

Electrical Safety:

Fire Safety:

Training:

Aluminum perforated mesh can withstand elevated temperatures, but its suitability for high-temperature applications depends on the specific temperature range and duration of exposure. Aluminum begins to soften at temperatures around 400°F (204°C) and can lose a significant amount of its tensile strength as it approaches its melting point, which is approximately 1,221°F (660°C) for pure aluminum. However, different alloys of aluminum might have varied temperature resistance. While it doesn’t catch fire or combust at high temperatures, its structural integrity can be compromised.

In applications where the aluminum mesh might be exposed to continuous high temperatures, it’s essential to consider potential material deformation, especially if the mesh is supporting any weight or is under tension. For short-term exposures or applications where temperatures remain below the softening point, the aluminum perforated mesh should perform adequately.

Furthermore, the rapid heat conduction property of aluminum can be an advantage or disadvantage depending on the application. It can help dissipate heat quickly but can also mean that the entire mesh heats up rapidly. In scenarios where high-temperature resistance is critical, it might be prudent to consider other materials like stainless steel or to use specialised high-temperature aluminum alloys. Always consult with experts or manufacturers when considering aluminum for high-temperature applications to ensure its suitability.

Maintenance of aluminum perforated sheets in coastal areas is essential due to the exposure to salt-laden air, which can accelerate corrosion. Here are some recommendations to ensure the longevity and aesthetics of the aluminum sheets in such environments:

Regular Cleaning:

Protective Coatings:

Inspection:

Avoid Contact with Dissimilar Metals:

Corrosion Protection:

Shelter:

Hardware and Fasteners:

Controlled Environment:

When aluminum perforated mesh is exposed to oxygen, it oxidizes, forming a thin protective layer of aluminum oxide on its surface. This oxidation process, unlike the rusting seen in metals like iron, serves as a beneficial shield for aluminum. This aluminum oxide layer acts as a resilient barrier, safeguarding the underlying metal from further oxidation. If scratched or damaged, the aluminum surface quickly reforms this protective oxide layer. However, challenges can arise in certain environments: coastal areas with salty air can lead to pitting corrosion, while direct contact with metals like copper can cause galvanic corrosion. Additionally, prolonged exposure to pollutants or aggressive elements can dull or discolor the aluminum’s appearance. To enhance the lifespan and appearance of the mesh, regular cleaning, the application of protective coatings and avoiding contact with dissimilar metals are recommended practices.

Check out our blog discussing What is Perforated Mesh. It will prove a useful read to help you to make an informed decision on which material would work best for you.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs, videos and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options