- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » How to Bend Angle Aluminium Bar: A Beginner’s Guide

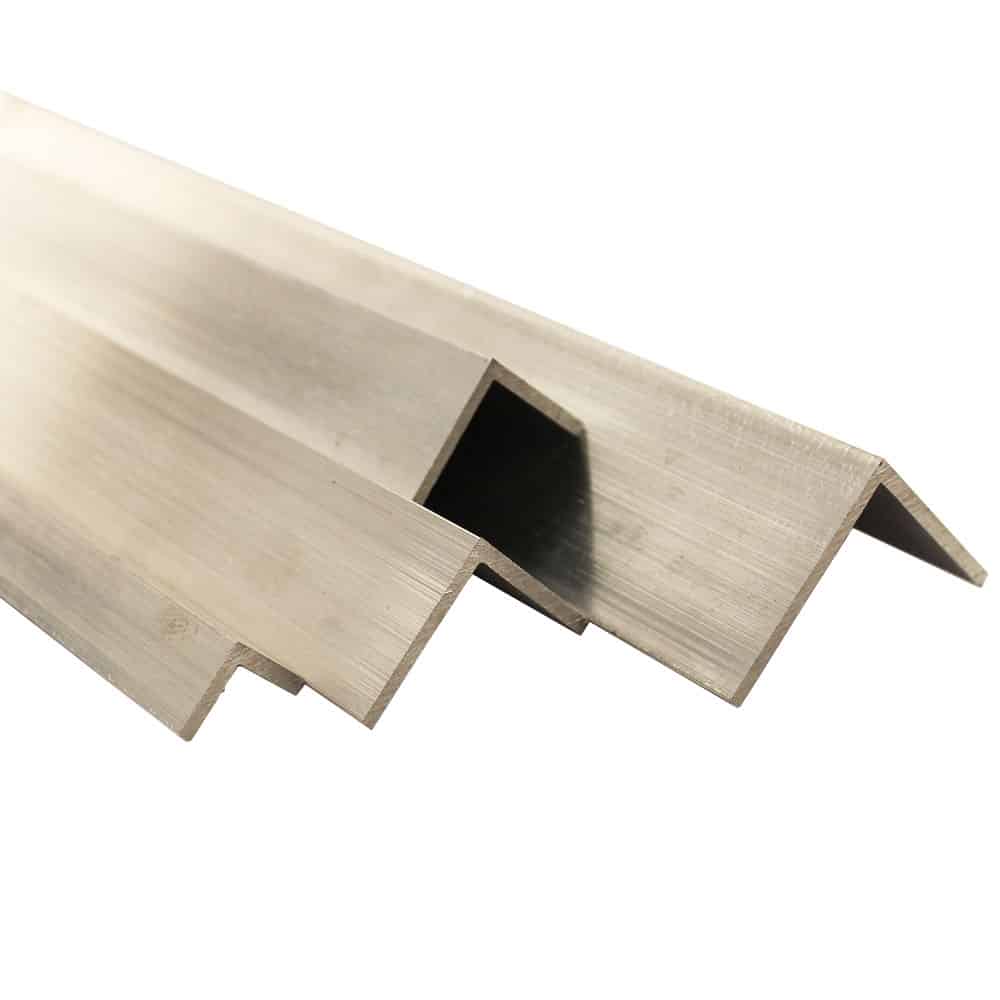

Bending aluminium angle can be a tricky task, especially for those who are new to metalworking. However, with the right tools and techniques, it is possible to achieve precise and accurate bends in good quality aluminium angle, which is what is supplied by Speciality Metals.

In this blog post, we’ll be discussing how to bend aluminium angle and providing you with a step-by-step guide to help you achieve perfect bends every time.

Let’s go…

Due to its versatility, aluminium is commonly used across a wide range of industries and applications. Metalwork often involves bending aluminium into shape to fit a particular curve at some point or another. If you’re doing some metalwork, you’re likely to come across aluminium that needs to be bent.

An aluminium angle will probably need to be bent, but because of the alloying elements within the metal, it isn’t as simple as just forcing the metal to bend. This will stress the metal and cause it to snap.

Because of this, bending aluminium angle sections is a contentious issue. We’ve compiled a guide on bending aluminium angles to help you avoid damaging your metal. We hope that this content proves to be of use to you.

You may also wish to visit our YouTube channel for a video guide showing how this can be achieved.

The best method of bending aluminum depends entirely on its thickness, the tools you have at your disposal, and the angle at which you need to bend the metal, as well as the thickness of the metal. Depending on whether or not you are confident enough with the alloying elements that your aluminium is composed of, a shrinker/stretcher tool could prove to be a good option. If you know the alloys that you are going to use, you can also heat them to achieve a bend.

Choosing the right tools and materials is the first step in bending aluminium angle. Among the tools you will need are a vice, a hammer, a ruler, a marker, and the aluminium angle you intend to bend. Aluminium angle is available from Speciality Metals in a variety of thicknesses and sizes.

After you have determined your angle, mark where you want to bend it. Draw a line where the bend should be with a ruler and a marker. A poorly executed bend will result from any deviation from the line at this stage.

The next step is to secure the angle in a vice. This will hold the angle in place while you bend it. Make sure the angle is secure in the vice, as any movement during the bending process will result in an uneven bend.

You can now start the bending process. Using a hammer, gently tap the angle along the line you have drawn. Start at one end of the line and work your way towards the other end, tapping the angle as you go. Take care not to apply too much force, as this can result in the angle bending too much or even cracking.

Once you have completed the bending process, you need to check your bend. Use a ruler or a protractor to measure the angle of the bend. If it’s not quite right, you can use the hammer to make any necessary adjustments

It is possible to bend many metals by heating them up and then bending them. The process can be done on large scale projects or at home using a blowtorch and a vice, with many people opting to do the home method with wood support. When it comes to bending aluminum, there are a few things to consider before using heat.

The first thing you need to know is what the alloying elements are in aluminium. Due to the reaction of different alloys when heated, some lose a lot of strength, resulting in brittle finishes. In some cases, heat treatment can restore some strength to aluminium, but if you’re doing a small-scale job or bending aluminium angles at home, you may not have the right tools.

It is also important to keep in mind that aluminium doesn’t glow when heated. Due to this, the melting point of aluminium is hard to determine. As a result of heating aluminium to bend it, it often burns holes in the metal when people bend it.

It’s important to use a temperature tool in order to avoid this. When the metal is annealed first, certain grades of metal can be bent safely with heat, but you must know the alloys to avoid fractures or holes.

Shrinker/stretcher tools are the most effective tool for bending aluminum angles. It may be worthwhile to buy your own depending on how often you work with metal. A metalwork shop will usually bend your metal using their shrinker/stretcher for a small fee if you only need to bend a few pieces or do not work with metal regularly. They usually charge a reasonable price for them.

A shrinker/stretcher works by either shrinking or stretching metal into a bend – as the name implies. You will need to shrink or stretch the aluminium angle depending on how you want it bent.

Pulling a lever compresses clamping jaws on the machine. Finding the best position for the bend to take shape and moving the metal through the jaws will require some effort on your part. A second pair of hands may be needed to help hold the metal and push it through the machine depending on the angle you’re working with.

The teeth of the jaws will leave some surface imperfections when you remove the metal from the clamp, but if you hammer the aluminium into shape, the finish will be much neater.

Even though this is the best method for bending aluminium, it isn’t without potential problems. The hardness of aluminum makes it a difficult metal to bend, resulting in stress fractures as a result.

Metal edges that have been stretched with the stretcher can be vulnerable to tearing. The risk increases if you intend to weld the metal later, but it’s still much lower than if you were to heat or hammer it yourself. After shrinking/stretching the metal, it leaves with a relatively even thickness. This method produces smoother results with less margin for error than other bending methods.

Bending aluminium angle is a skill that takes time and practice to master. However, with the tips outlined in this blog post, you’ll be able to achieve professional-looking bends in no time. Remember to take your time, work carefully and double-check your measurements to ensure a precise and accurate bend. And if you need any further guidance or advice, don’t hesitate to contact Speciality Metals for assistance.

Happy bending!

As always, thank you for checking out our blog. We hope that this helps you with your project.

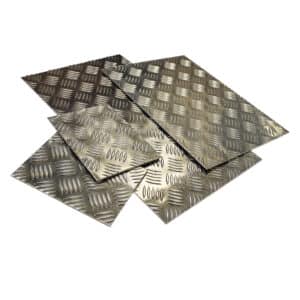

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options