- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Ferrous vs. Non-Ferrous Metals: Understanding the Core Differences and Applications

It’s not just academic how ferrous and nonferrous metals differ in metallurgy; it’s a fundamental classification that affects materials across a wide range of industries, from construction to autos to electronics.

Despite their similarities, ferrous metals, known for their iron content, and non-ferrous metals, known for their lack of iron, both possess unique properties that make them suitable for different applications. Choosing materials for a project requires engineers, designers, and fabricators to understand these differences.

Speciality Metals offers both ferrous and non-ferrous metal products, and our goal is to provide you with a comprehensive comparison so that you can choose the right metal type for your application. When constructing a building, manufacturing machinery, or crafting decorative items, knowing the right metal to use can greatly affect durability, functionality, and aesthetics.

And if you are in a hurry, we have made a quick chart at the bottom of this article which quickly explains which metal falls into which category.

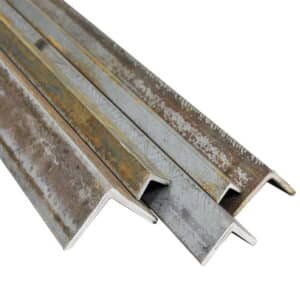

Iron is the primary characteristic of ferrous metals. In this category you will find a wide range of metals, including steel and cast iron, both of which are crucial to construction and manufacturing because of their strength and durability. Because ferrous metals contain iron, they are magnetic, making them indispensable for motors and electrical appliances. However, when exposed to moisture, ferrous metals are also prone to corrosion, a limitation that is often mitigated by galvanising.

Non-ferrous metals, on the other hand, do not contain iron. Metals in this category include aluminium, copper, zinc, and titanium, each prized for specific properties such as corrosion resistance, low density, and non-magnetic properties. Aluminium, for example, is lightweight, yet strong, making it an excellent choice for aerospace applications, including sheet metal and extrusions. Copper’s exceptional conductivity makes it indispensable for electrical wiring and plumbing fixtures. Generally, non-ferrous metals are more resilient to corrosion and rust, offering longevity and durability in environments where ferrous metals might lose their durability.

There is more to this distinction than just the presence or absence of iron. It’s about their mechanical and chemical properties, which, in turn, influence their suitability for various applications. The steel used in building frameworks and the copper wires that power our homes are both ferrous metals that play a crucial role in our daily lives. We provide a broad range of ferrous and non-ferrous metals to cater to the diverse needs of our customers.

Due to their inherent physical and chemical properties, ferrous metals are the backbone of modern industrial applications. The strength of ferrous metals makes them indispensable in construction, automotive, and manufacturing industries. As a result of the metal’s atomic structure and the addition of carbon, it has a great deal of durability and load bearing capacity. As a result of their iron content, ferrous metals also have magnetic properties, which are crucial to the production of motors, generators, and electrical appliances.

However, ferrous metals are not without their limitations. Corrosion is a well-known drawback of these metals, with moisture exposure leading to rust, which can compromise their integrity over time. As a result, ferrous metals have historically been used in applications where durability and resistance to environmental elements are essential.

Cast iron and steel are two common ferrous metals. The versatile alloy of iron and carbon, steel, is used in everything from skyscraper frames to household appliances. Its subcategories, such as carbon steel, alloy steel, and stainless steel, offer different degrees of strength, malleability, and wear resistance. Cast iron is used to manufacture pipes, automotive components, and cookware because of its excellent casting properties and wear resistance.

To combat corrosion, ferrous metal technology has advanced significantly. The corrosion resistance of stainless steel, an alloy containing iron, carbon, and a minimum of 10.5% chromium, has made it an ideal material for medical instruments, kitchen utensils, and architectural facades. Chromic oxide forms on the metal’s surface when chromium is added, effectively shielding it from moisture and preventing rust.

Another notable innovation is galvanised steel, which is coated with zinc to prevent corrosion. Besides extending the life of steel products, this process also allows them to be used in more demanding environments, such as outdoor construction and marine applications.

Technology advancements in ferrous metals demonstrate the industry’s commitment to overcoming traditional limitations, enhancing the material’s properties to meet modern demands. Whether it is structural steel that frames our cities or stainless steel that decorates our kitchens, ferrous metals continue to drive innovation and sustain the growth of industries worldwide.

Non-ferrous metals have distinct properties that set them apart. As a result of their inherent nonmagnetic property, corrosion resistance, and generally lighter weight, they can be used in a variety of applications across a wide range of industries. Non-ferrous metals play a variety of roles in industrial and consumer applications at Specialty Metals.

Aluminium is a prime example, known for its lightweight yet strong characteristics. There is a wide use of this material in the aerospace industry for the manufacture of aircraft components as well as in the automotive industry for reducing vehicle weight and improving fuel efficiency. The aluminum product range we offer, from sheets to extrusions, is tailored to the needs of these sectors by providing materials that balance durability with ease of handling.

With its excellent electrical conductivity, copper is the preferred material for electrical wiring, electronics, and renewable energy technologies, such as solar panels and wind turbines. Due to its thermal conductivity, it is also ideal for heat exchangers and cookware. Speciality Metals offers copper products suitable for both industrial and domestic applications, ensuring high-quality materials.

Its strength-to-weight ratio and corrosion resistance make titanium an ideal material for aerospace, medical implants, and high-performance sporting goods. Titanium’s specialised applications highlight the diversity of non-ferrous metals and their role in technology advancement and quality of life improvement, despite its higher cost than aluminium or copper.

One of the most significant advantages of non-ferrous metals is their recyclability and sustainability. Aluminium and copper, for example, can be recycled indefinitely without losing their quality, contributing to a circular economy and reducing environmental impact. In green building initiatives and environmental conservation efforts, materials play a critical role in achieving sustainability goals.

It is essential to understand the specific requirements of the application before selecting the right metal for a project. There are many factors to consider, including weight, strength, corrosion resistance, and cost. In construction, ferrous metals like steel are preferred for their strength and cost-effectiveness, while non-ferrous metals like aluminium and copper are used for lightweight and corrosion-resistant applications.

Mechanics, welding, and finishing properties of different metal types must also be understood when working with them. Due to their carbon content, ferrous metals are typically easier to weld and machine, whereas non-ferrous metals like aluminium require special welding techniques to avoid warping or oxidation.

Ultimately, the choice between ferrous and non-ferrous metals depends on the project’s demands and the material’s properties. In addition to meeting the project’s requirements, understanding these distinctions ensures longevity, functionality, and aesthetic appeal of the selected metal.

Ferrous and non-ferrous metals are at the forefront of technological innovation and sustainable practices in metal use. The push to develop materials that can meet the performance and environmental demands of the 21st century is leading to significant advancements in metal technology. New alloys and composite materials that harness the best properties of ferrous and non-ferrous metals are being developed, promising to revolutionise industries from construction to electronics.

The lightweight and corrosion-resistant properties of non-ferrous metals like aluminium and copper are valuable for solar panels and wind turbines in the field of renewable energy. Similarly, the electric vehicle (EV) industry relies on these metals for battery housings and electrical components, driving demand for lighter and more efficient materials.

Another sector poised for transformation is smart construction. A combination of ferrous metals and advanced coatings and treatments provides the strength and durability needed for building frameworks, while non-ferrous metals can be used for critical elements exposed to harsh environments.

| Metal | Type |

| Steel | Ferrous |

| Iron | Ferrous |

| Stainless Steel | Ferrous |

| Cast Iron | Ferrous |

| Aluminium | Non-Ferrous |

| Copper | Non-Ferrous |

| Brass | Non-Ferrous |

| Titanium | Non-Ferrous |

| Zinc | Non-Ferrous |

| Lead | Non-Ferrous |

| Nickel | Non-Ferrous |

For material selection across a wide range of applications, understanding ferrous and nonferrous metals is essential. Every type of metal plays a crucial role in modern engineering and design, from ferrous metals to non-ferrous metals. Our exploration of metal technology has shown that advances in this area not only offer enhanced properties, but also open the door to innovative and sustainable applications.

With ongoing research and development, metals will become stronger, lighter, and more environmentally friendly in the future.

At Speciality Metals, we offer a wide variety of metal products. By committing to quality and innovation, we remain at the forefront of the metal industry, ready to support your projects with the best materials available.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options