- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Menu

Home » Everything You Need to Know About Bright Mild Steel Flat Bar

Steel bars are one of the most versatile materials that are widely used in different industries, including construction, engineering, manufacturing, and fabrication.

Steel comes in various forms, including flat bar, round bar, square bar, and more. In this blog post, we will be focusing on bright mild steel flat bar and everything you need to know about it.

Let’s go…

Among the steel products that we supply at Speciality Metals, we have a large selection of mild steel flat bars available in a variety of shapes and sizes. Despite the fact that bright mild steel flat bars are one of the most versatile types of steel, and can be used across a wide range of applications – whether they are commercial or otherwise – few people are aware what they are, let alone how useful they can be.

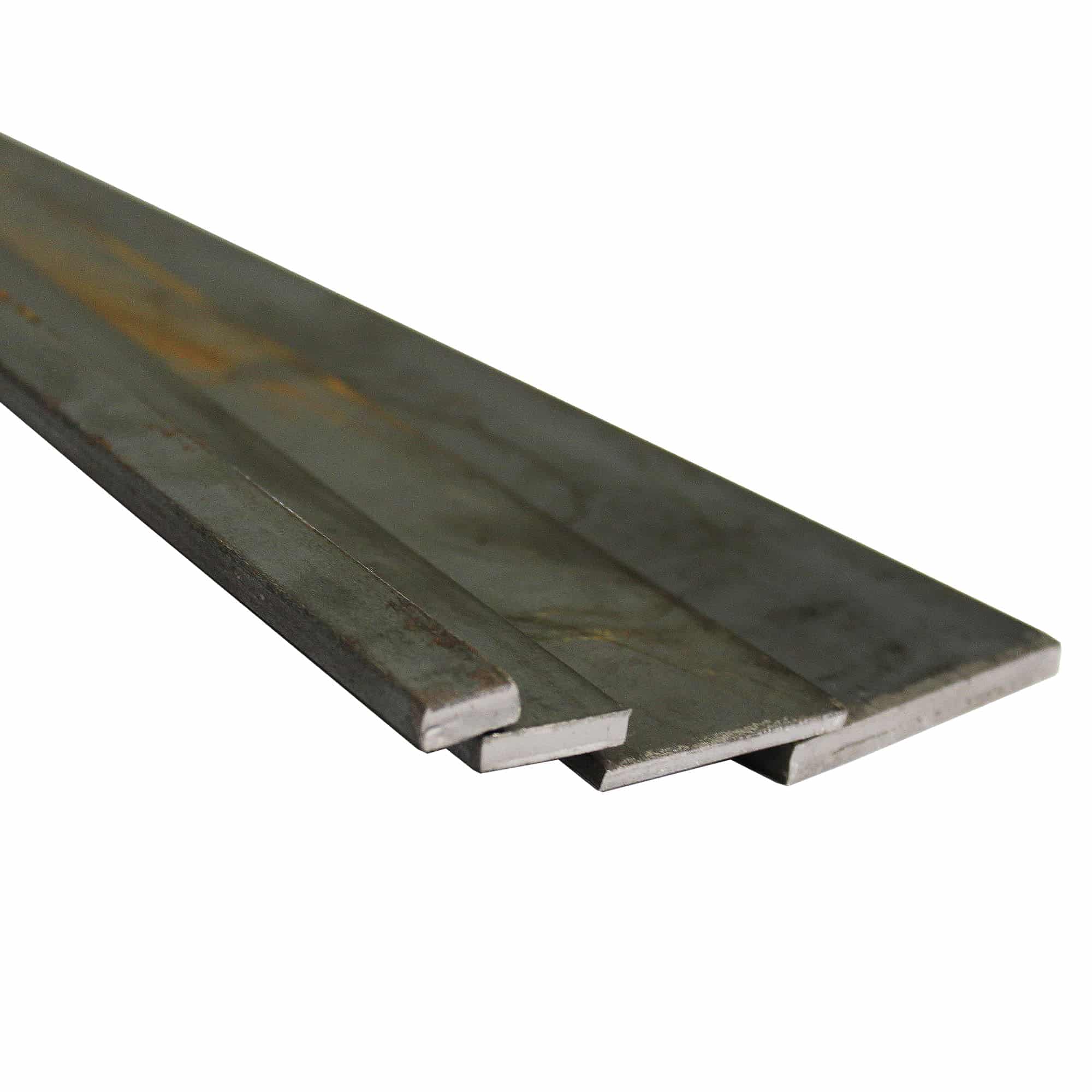

As well as being known as “black mild steel flat bar,” bright mild steel flat bar is a flat steel strip that is available in a variety of thicknesses and widths. Usually, the term “bright” refers to the way in which the surface of the steel is shiny and smooth. The surface of the steel is smooth and uniform because it is rolled over a series of rollers in order to create a smooth and uniform surface. It is an excellent choice to create different shapes and objects using mild steel flat bar because of its strength, durability, and malleability, which allows it to be used in a variety of ways.

In order to help you make the most informed purchasing decision, we’ve come up with a guide that explains exactly what bright flat bars are and what they can be used for, allowing you to come up with more informed decisions when buying.

The use of mild steel as well as bright mild steel is hugely beneficial. There is a lot of use for the latter in the manufacture of car parts and wires, but it is also used in the manufacture of smaller items such as cutlery and screw fixings as well.

Engineering is the main application for bright mild steel. Due to its strength and hardness, it is typically used in low-stress applications because it can be susceptible to internal stress. Bolts, axles, and all kinds of machinery commonly use bright mild steel as a general material.

A flat bar is easily cut and welded, and it’s commonly used to create various kinds of frames and plates. It is also possible to use them on a larger scale within construction, but they must be treated to prevent rusting

Due to their different manufacturing processes, bright mild steel differs from regular mild steel. Cold rolling is the process by which bright mild steel is manufactured, sometimes called cold drawing and finishing.

Processed at a temperature below recrystallisation, this means the steel is not recrystallized. Steel can change its grain structure when it reaches its recrystallization temperature. As a result of the cooling process, the metal has less tensile strength and distortions, making the processing time shorter and cheaper.

In contrast, cold drawn steel is processed at room temperature. To reach the finished product, additional pressure and several passes through the machine rollers are required.

The carbon content of steel in all its forms makes it exceptionally strong, although the higher the carbon content, the more difficult it is to manipulate and mould. Steel that contains less carbon is more malleable, making it easier to work with, but it has the disadvantage of being less strong than steels that contain more carbon.

When mild steel is cold rolled, it undergoes increased pressure, which improves its tensile strength. Therefore, bright mild steel is more resistant to pressure and tension than traditional mild steel.

As well as its superior finish, bright mild steel has a higher degree of refinement than mild steel. In the hot rolling process, metal is heated above its recrystallisation temperature. Consequently, as the metal cools and shrinks, there may be deformities and thickness discrepancies. Additionally, the dimensions can be slightly off.

Compared to hot rolling, cold rolling provides a smoother surface and a better finish

The versatility of bright mild steel flat bar allows it to be used in a variety of applications due to its wide range of properties. In addition to being strong, durable, and malleable, it is also tough and ductile. This low-cost material is easy to work with and can be used in a wide range of industries, including construction, engineering, and manufacturing. Bright mild steel flat bar is an excellent choice for your next project if you are looking for a reliable material.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options