- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Decoding Aluminium Grades: Your In-Depth Guide by Speciality Metals

Aluminium, known for its lightweight nature and impressive strength, plays a pivotal role across a multitude of industries.

From the high-flying realms of aerospace to the everyday convenience of packaging, aluminium’s versatility is unmatched.

Its unique combination of properties – including malleability, conductivity, and corrosion resistance – makes it an invaluable resource in modern engineering and design. Aluminium’s widespread use is a testament to its adaptability and efficiency in meeting diverse application requirements.

This guide aims to shed light on the intricate world of aluminium grades. Each grade of aluminium offers a unique set of characteristics tailored to specific applications, and understanding these variations is key to optimizing its use.

At Speciality Metals, we pride ourselves on not just supplying aluminium but also on helping our clients navigate through myriad grades to find the perfect match for their specific needs.

Join us as we delve into the details of aluminium grades, their properties, and applications, demonstrating how Speciality Metals can cater to your specific aluminium requirements with precision and expertise.

Let’s go…

Lightness and strength are two of the characteristics that make aluminium stand out in the metal world. It is a silvery-white, soft, non-magnetic metal that is the third most abundant element in the Earth’s crust. The malleability of aluminium makes it suitable for forming into various shapes and sizes, and its non-toxic nature allows it to be used in food-related applications. Furthermore, its conductivity makes it highly valuable in electrical applications, where it competes closely with more expensive copper.

The journey of aluminium in industry and technology is a story of innovation and evolution. A precious metal once considered more valuable than gold, aluminium has become a cornerstone of industrial development. The discovery of the Hall-Héroult process in the late 19th century paved the way for mass production of aluminium and firmly anchored it in technological advancement.

The sustainability of aluminium is one of its key appeals. In the circular economy, it plays a significant role as a fully recyclable material. Around 95% of the energy required to produce aluminium is saved by recycling it, significantly reducing its environmental impact. Since aluminium can be recycled indefinitely without losing its properties, its recyclability does not compromise its quality.

Aluminum’s grading system categorizes its numerous alloys according to their composition. Each series is distinguished by a specific alloying element that enhances the metal’s natural properties. Each series offers unique advantages and is tailored to specific applications.

The composition of each grade directly affects its properties, such as strength, malleability, and corrosion resistance, making selecting the right aluminium grade essential. Speciality Metals understands these nuances and guides our customers in selecting the right aluminium grade.

The variety of aluminium grades, each tailored for a specific application, illustrates the versatility of aluminium. Explore the properties and applications of some of the popular aluminium grades – 6061, 7075, and 1100.

6061 Aluminium: Known as a ‘jack-of-all-trades’ material, 6061 aluminium is a member of the 6000 series. A combination of magnesium and silicon, it offers strength, weldability, and corrosion resistance. It is commonly used in the construction of bicycle frames, aircraft wings, and marine fittings. As a result of its ability to withstand diverse environments without corroding, it is ideal for outdoor applications. The Golden Gate Bridge’s pedestrian walkway uses 6061 aluminium due to its strength and resistance to the marine environment.

7075 Aluminium: As a member of the 7000 series, 7075 is alloyed with zinc and renowned for its strength. Aerospace and military applications, including fighter jet frames and spacecraft parts, require it because it is almost as strong as steel, yet a fraction of the weight. Its use in the Mars Rover’s chassis illustrates its durability and reliability.

1100 Aluminium: As part of the 1000 series, this grade is almost pure aluminium (99% purity). It is highly ductile, corrosion-resistant, and has excellent thermal and electrical conductivity. The properties of this material make it suitable for applications that require a high degree of malleability, such as HVAC ductwork, chemical equipment, and kitchen utensils. As a result of its high conductivity, it is ideal for electrical applications, such as transformer linings.

Each of these grades demonstrates aluminium’s adaptability and efficiency in meeting specific industry needs, from space exploration to everyday kitchenware.

Selecting the appropriate aluminium grade for your project is crucial for ensuring durability, functionality, and cost-effectiveness. Here are key factors to consider:

Strength Requirements: High-strength grades like 7075 are ideal for aerospace and automotive components requiring high strength. Lower-strength grades like 1100 may be sufficient for less intensive applications, such as decorative panels.

Corrosion Resistance: Corrosion resistance is essential in environments exposed to weather or chemicals. Corrosion-resistant grades like 6061 are suitable for outdoor or marine applications.

Workability: It is important to use a grade with good workability, such as 1100 or 3000 series, if the project involves forming, bending, or welding.

Budget Constraints: Different grades have different costs. Compared to alloyed grades like 7075, pure grades like 1100 tend to be more affordable.

Application Environment: The environment conditions in which the aluminum will be used (e.g., extreme temperatures, chemical exposure, etc.) need to be considered.

In order to ensure our clients choose the right grade for their specific requirements, Specialty Metals guides them through these considerations. In addition to supplying aluminium, we understand its nuances and applications. To ensure your project benefits from the optimal aluminium grade, we provide consultations and custom solutions.

Speciality Metals offers a wide selection of aluminium products that cater to a variety of industrial and commercial applications.

We offer a variety of grades, each selected for its quality and performance.

We hope that our selection of materials meets and exceeds client expectations, from the highly versatile 6082 grade, ideal for structural components and architectural projects, to the robust 7075 grade, popular in aerospace and defence applications.

Our most popular aluminium material is our 1050 sheet metal. This is a constant favourite of our customer base.

In addition to being diverse, our range is also synonymous with quality. In order to ensure that our aluminum products meet both international standards and the specific requirements of our customers, each product in our catalog undergoes rigorous testing and quality control processes.

With our commitment to quality, we ensure that our aluminium products are not only reliable, but also long-lasting and dependable.

Because Speciality Metals understands that each project has unique requirements, we also offer custom solutions.

Each aluminium grade offers unique properties and advantages for a variety of applications, making it a fascinating world of aluminum grades. At Speciality Metals, we go beyond merely supplying aluminium; we strive to match each client’s needs with the best aluminium grade. With our extensive range and commitment to quality and custom solutions, we’re more than a supplier, we’re a partner in your aluminium projects.

Explore the possibilities with our aluminium products. Contact Speciality Metals for guidance, custom solutions, or to discuss your specific aluminium requirements. Let’s turn your project visions into reality together.

As always, thank you for checking out our blog. We hope that this helps you with your project.

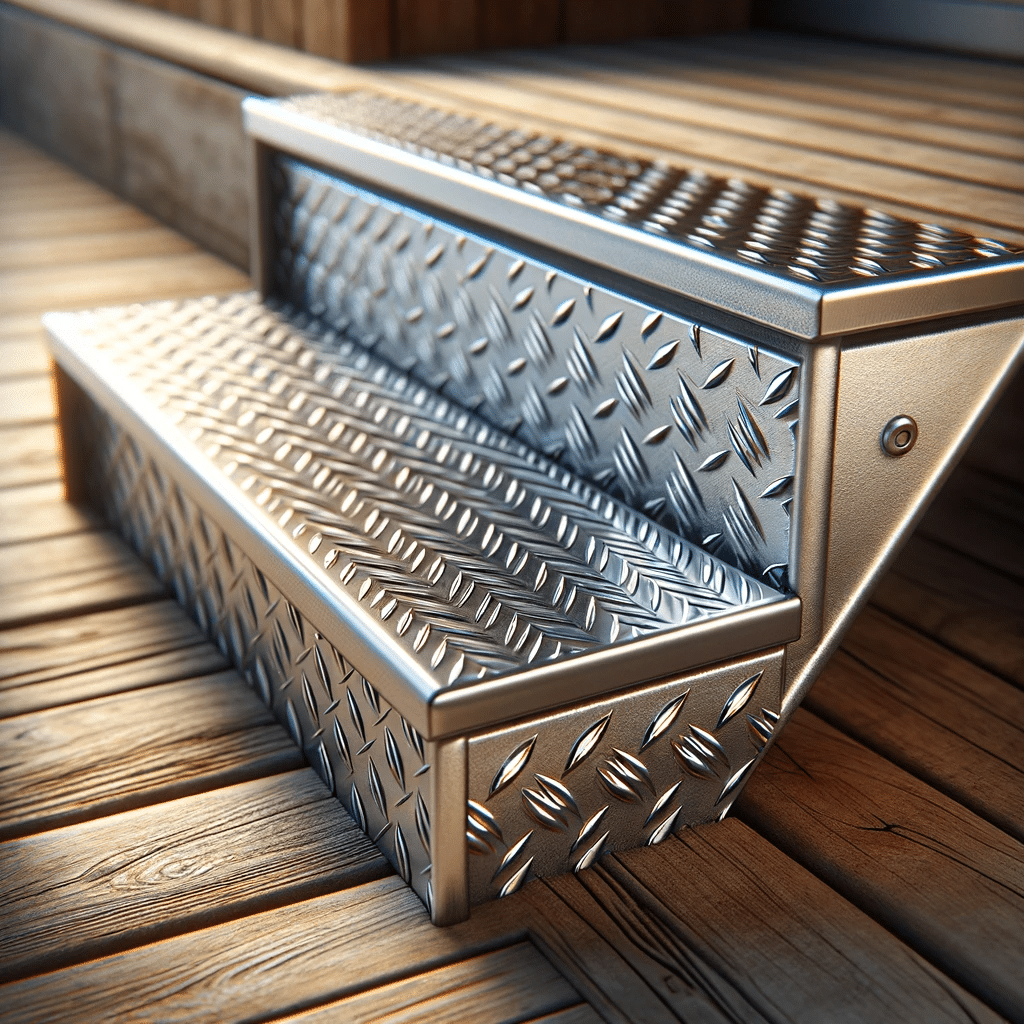

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options