- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Cutting Metal Sheet with a Guillotine

Cutting metal sheets is a foundational process in the metalworking industry. From the automotive sector to construction, metal sheets serve various purposes and have to be shaped and sized accordingly. One of the most widely used tools for this purpose is the guillotine. Let’s dive deep into understanding this powerful machine and the art of cutting metal sheets with it.

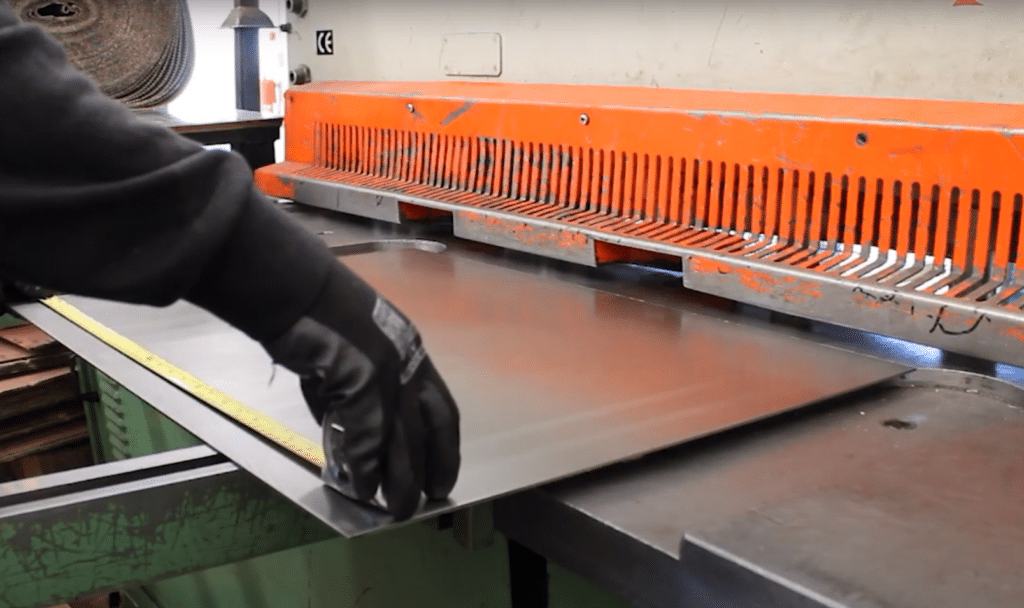

A guillotine, in the context of metalworking, is a machine used for cutting large sheets of metal. It’s designed to make straight-line cuts, functioning much like the paper cutter you might find in an office but on a much larger, heavier-duty scale. The primary component of a guillotine is its large blade, which swiftly comes down to slice the metal sheet placed below.

Positioning the Metal Sheet: Before the actual cutting process, the metal sheet is aligned on the flat bed of the machine. Proper alignment ensures that the cut is accurate and straight.

Setting the Measurements: Modern guillotines come with digital readouts and guides that allow you to precisely measure where the cut will be made.

Safety Measures: Before activating the blade, safety clamps hold the sheet in place to prevent any movement during cutting.

Cutting: Once everything is set, the blade drops – either manually, hydraulically or mechanically – to cut the metal sheet.

Precision: Guillotines offer unparalleled precision in making straight-line cuts. With proper measurements and a sharp blade, the tool can consistently produce straight cuts.

Efficiency: Especially in settings where many sheets need cutting, a guillotine can swiftly process large volumes, boosting productivity.

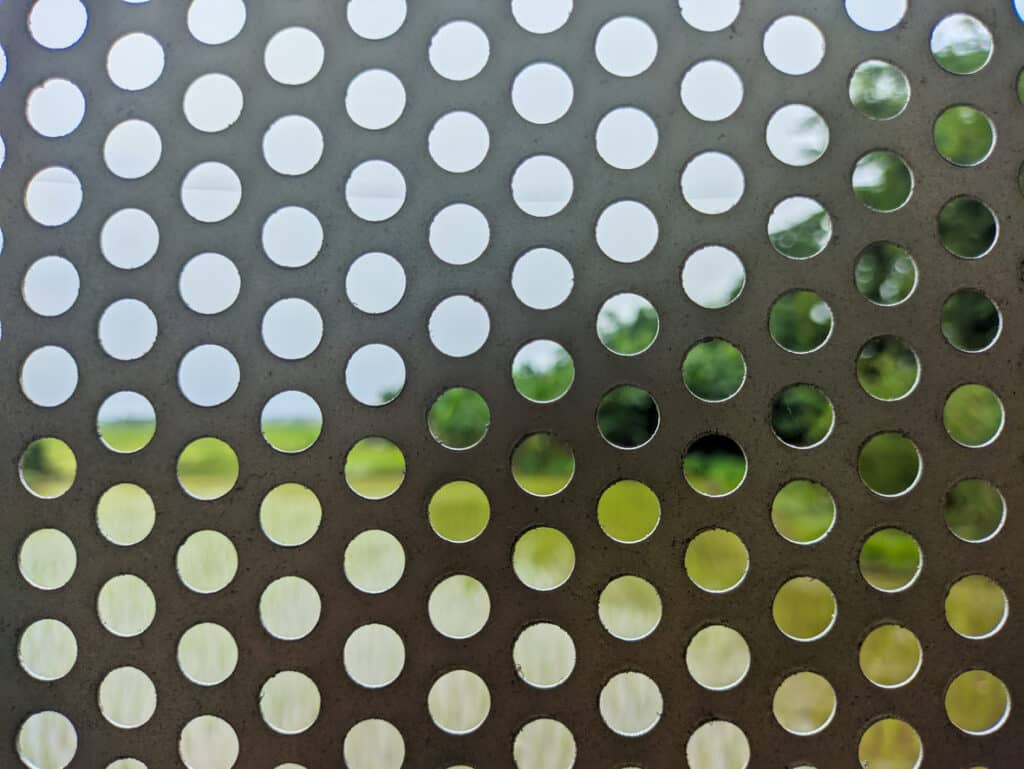

Versatility: Guillotines can handle a variety of metal sheets, from aluminum to stainless steel, provided you have the right kind of blade and machine strength.

Safety: With modern safety features, the risk of accidents is minimised. These features may include light guards, safety clamps and emergency stop functions.

The guillotine, with its blend of precision and power, is a testament to the advances in metalworking tools. It offers industries the ability to quickly and accurately shape metal sheets, paving the way for the creation of countless products that make up our modern world. Like all machinery, it demands respect and careful handling, but with proper use and safety measures, it can be an invaluable asset to any metalworking shop.

Using a guillotine requires utmost caution due to the inherent risks involved.

Guillotines play a pivotal role across a range of industries due to their precision and efficiency in cutting straight-line metal sheets. In the realm of manufacturing and fabrication, they are instrumental in producing components for machinery, vehicles and appliances. The automotive industry leans heavily on guillotines to shape body panels and chassis components, while the aerospace sector utilizes them for crafting precise aircraft components like paneling. Construction projects often demand guillotines for sizing metal beams, girders and roofing sheets. Similarly, shipbuilding processes require them to shape the vast sheets of metal for ship hulls. In the electrical industry, guillotines prove invaluable for creating panels and enclosures, and HVAC professionals rely on them for crafting ductwork and vents. Artists dabbling in metalwork, signage manufacturers and even those in the jewelry-making business also harness the guillotine’s capabilities for precision cutting. Lastly, the railway industry makes use of guillotines for crafting integral parts of trains and related infrastructure. The ubiquity of the guillotine across these sectors underscores its indispensable nature in ensuring both functionality and aesthetics in various products and structures.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about cutting sheet metal recently so why not check it out.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options