- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Comparing Aluminum vs. Steel Flat Bars: Which Material Suits Your Project?

The debate between aluminum and steel flat bars has been ongoing for decades, with both materials showcasing their unique properties and strengths. As industries evolve, the demand for versatile and durable materials grows.

At Speciality Metals, we recognise the importance of making informed decisions when selecting the right material for your project.

Let’s dive deep into the comparison between aluminum and steel flat bars to guide you towards the perfect fit for your needs…

First let’s discuss these two disparate metal options in depth:

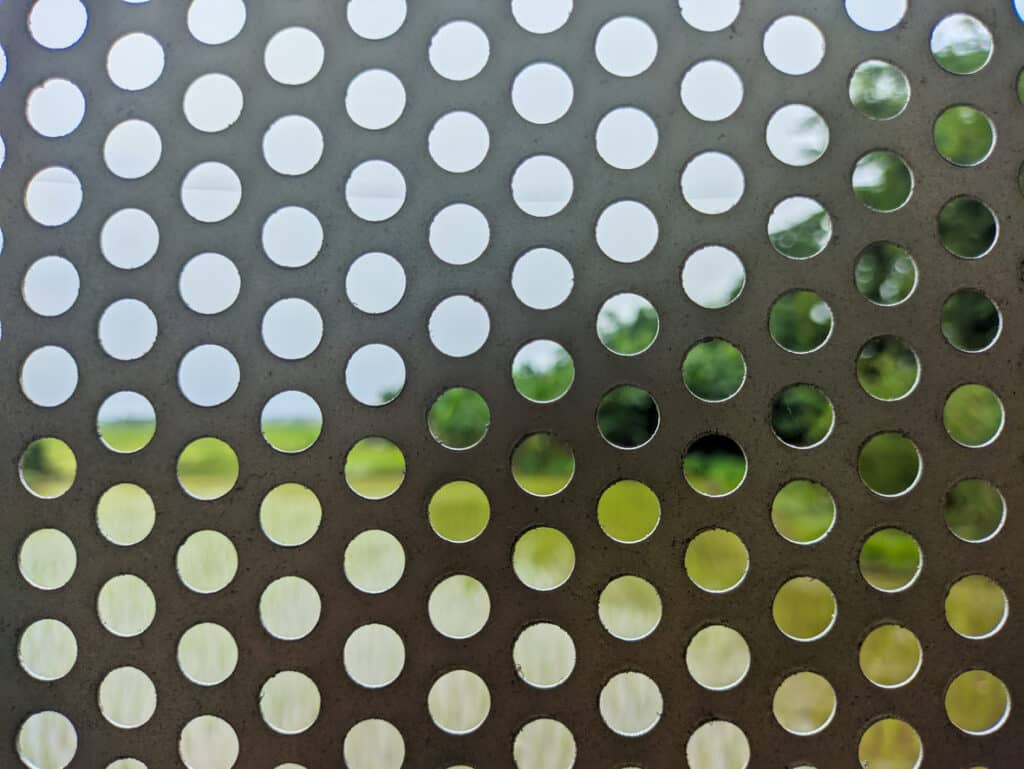

Customers opt for aluminum flat bars not only due to their lightweight attributes but also for the myriad advantages this versatile material brings to the table. Structures exposed to harsh environments benefit from aluminum’s corrosion resistance, which makes it a smart choice. In electronics and heat dissipation applications, its remarkable thermal and electrical conductivity makes it indispensable.

Furthermore, aluminum’s recyclability and lower energy consumption during recycling align with eco-conscious initiatives due to its sustainability factor. The product’s design flexibility, cost-efficiency, and non-magnetic properties further enhance its appeal.

Aside from their weight reduction properties, aluminum flat bars offer customers a range of properties that make them an excellent choice for a wide range of applications.

Properties:

Applications:

Aerospace, automotive structures, building exteriors, and various decorative purposes benefit immensely from aluminum flat bars.

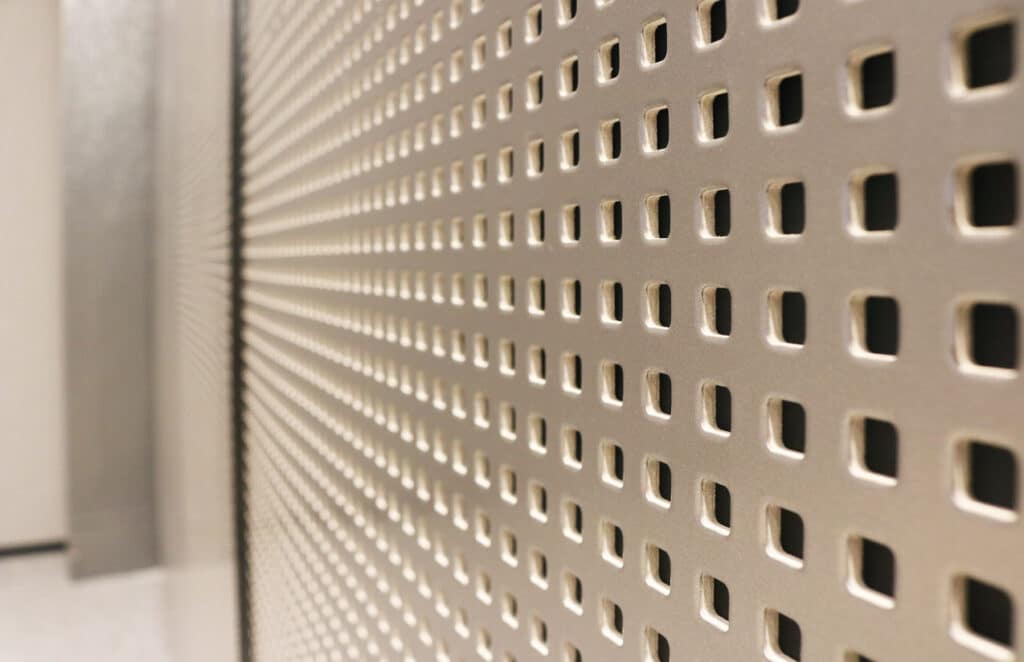

Steel flat bars are the go-to choice for projects where structural integrity and longevity are paramount because of their unmatched strength and durability. With its various grades and finishes, steel can be tailored to specific applications, whether they demand high-strength support or corrosion resistance. Steel flat bars are an attractive option for high-performance projects on a budget due to their superior weldability and cost-effectiveness. In industries requiring intricate fabrication, steel’s recyclability aligns with sustainability goals, reducing its environmental impact.

Additionally, steel’s non-magnetic properties make it a reliable choice in applications sensitive to magnetic interference.

Altogether, steel flat bars offer customers a compelling array of advantages that go beyond raw strength, positioning them as an essential choice across diverse projects and industries where durability, reliability, and cost-efficiency are key considerations.

Properties:

Applications:

From construction beams, bridge components, to machinery parts, steel flat bars play an integral role in numerous industries.

Steel flat bars are the preferred choice in applications requiring structural integrity and longevity due to their unmatched strength and durability. Among industries like construction, manufacturing, and heavy infrastructure, their versatility, superior weldability, cost-effectiveness, and precision machinability make them a preferred choice.

Aluminum flat bars, on the other hand, are gaining popularity, especially in applications that require weight reduction, corrosion resistance, and sustainability. Lightweight, corrosion-resistant, and eco-friendly, they are ideal for industries such as aerospace, automotive, electronics, and architecture.

The popularity of aluminum flat bars varies based on the specific industry, project requirements, and environmental factors. A comprehensive assessment of factors such as load bearing capacity, corrosion resistance, machinability, aesthetics, budget, and sustainability goals should guide the decision. With Speciality Metals, customers have access to a wide range of aluminum and steel flat bars, regardless of popularity, for their unique projects, to meet their objectives efficiently and effectively.

The answer depends on your project’s specific requirements:

At Speciality Metals, we understand the intricacies of each project. We offer both aluminum and steel flat bars in myriad sizes. Our team is dedicated to ensuring you get the best quality materials tailored to your needs.

For a detailed look into our offerings and to find the perfect flat bar size, visit our product pages. Embrace the strength of steel and the versatility of aluminum with Speciality Metals.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options