- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Bending and Forming 304 Stainless Steel Flat Bars: A Practical Guide

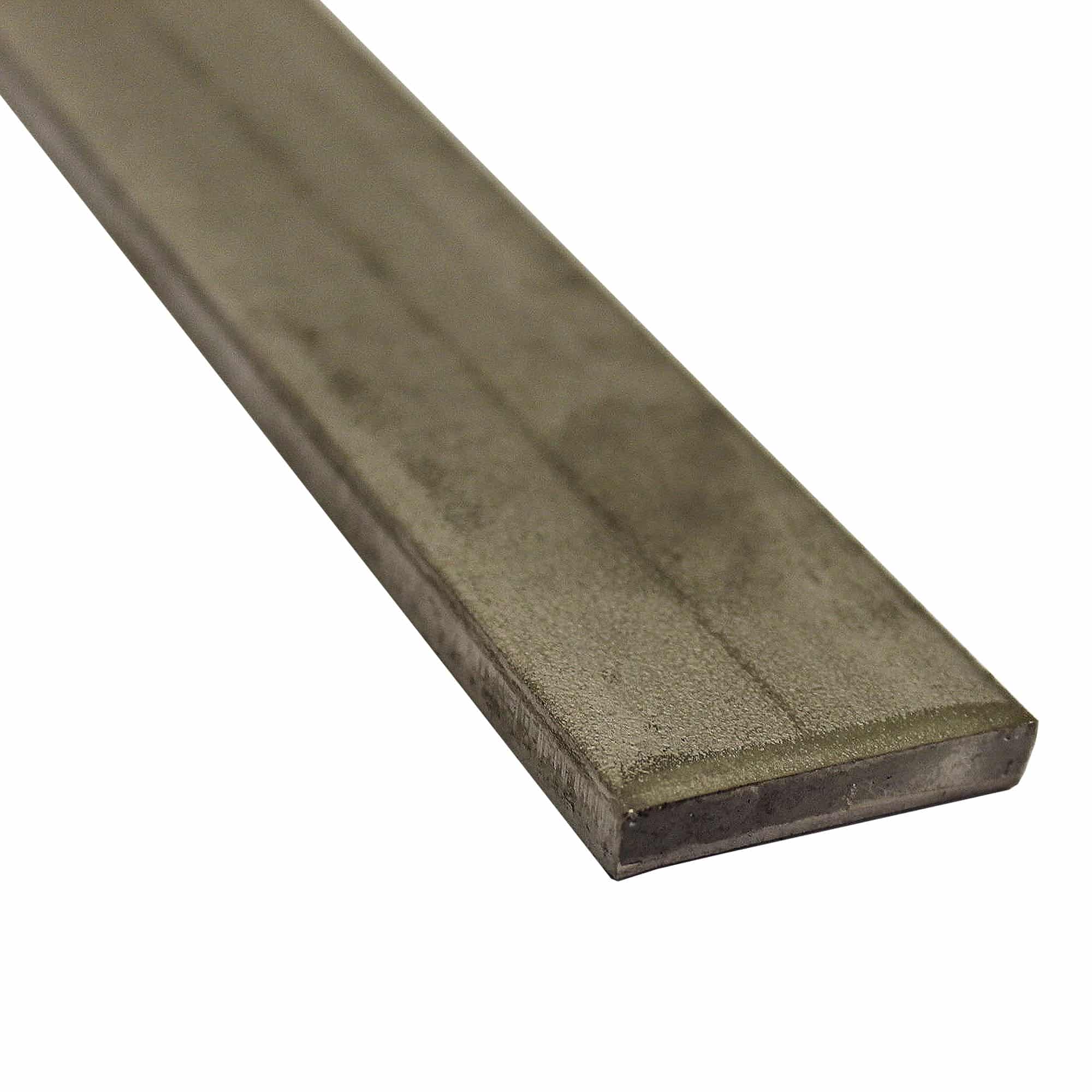

The versatility of 304 stainless steel, with its excellent balance of strength and corrosion resistance, makes it a staple in the metalworking industry. One of the most common profiles for this grade is flat bar, which is essence a metal strip.

The possibility of bending and forming 304 stainless steel flat bars to suit various applications offers hobbyists and professional metalworkers many possibilities. In addition to construction brackets, the material is widely used in decorative elements.

In order to achieve the desired form with 304 stainless steel, you need to understand the material’s properties and use precise techniques.

This guide offers a comprehensive look at how to bend and form stainless steel flat bars. There is a quick-read summary at the bottom of the article if you are short of time.

Let’s get into it..

Because of its specific composition, primarily iron, with chromium and nickel, 304 stainless steel is notorious for its robustness and corrosion resistance. Because of its austenitic crystalline structure, the alloy exhibits remarkable formability and weldability. It is still the work hardening rate of the material that has a significant impact on its bending processes. When 304 stainless steel is deformed, its strength increases, making subsequent bending more challenging and requiring careful consideration of tools and techniques.

From kitchen utensils to architectural frameworks, 304’s balanced attributes make it an ideal candidate for a wide range of applications. Although its formability is slightly lower than some other non-austenitic grades, its corrosion resistance is particularly valuable in acidic or highly saline environments. Anyone looking to bend or form 304 stainless steel must understand these properties, as they dictate the material’s behavior under stress and influence shaping methods.

Due to its lower melting point and softer nature, aluminium is easier to bend and form than 304 stainless steel, which requires more force to manipulate. When working with 304 stainless steel, more sophisticated equipment or techniques are required.

Due to its chromium content, 304 stainless steel offers enhanced corrosion resistance over mild steel because it forms a passive layer of chromium oxide on its surface that prevents corrosion.

While mild steel is easier to bend and more cost-effective than 304 stainless steel, it lacks corrosion resistance and requires protective coatings to stop rusting.

Preparation is the key to successfully bending 304 stainless steel flat bars. Clean the bars thoroughly to remove any contaminants that could affect the quality of the bend. Precision is equally important at this stage to ensure that the final form meets the project specifications. During measurements, it is important to take into account the material’s tendency to spring back after bending.

It is crucial to select the right tools and equipment. Press brakes or bending machines equipped with stainless steel dies and punches are ideal for clean and precise bends. The work-hardening characteristic of the material is accommodated by these tools, allowing for better control of the bending process. Consider the thickness of the flat bar and the desired radius when determining the required force and whether heat assistance is needed.

304 stainless steel flat bars can be bent accurately by following these steps and selecting the appropriate equipment, ensuring the material’s integrity and the project’s success.

In order to bend 304 stainless steel flat bars effectively while maintaining their integrity, a strategic approach is required. A variety of factors influence the choice of bending technique, including the radius of the bend and the thickness of the material. V-bending, rotary bending, and roll bending are among the methods used. Each has its own advantages and challenges.

V-bending – This is the most common technique, involves pressing the material into a V-shaped die. A high degree of control can be achieved with this method, which is effective for both sharp and gradual bends. It can, however, cause significant work hardening at the bend site, resulting in cracking if not managed correctly.

Rotary bending – This is another popular method, where the material is bent around a rotating die. With this technique, the physical stress on the steel is minimised, reducing the risk of cracking and work hardening as a result. Although specialised equipment is required for this process, it is particularly suitable for complex shapes and coils.

Roll bending – In this process the stainless steel bar is passed through a series of rollers to achieve a curved shape. Using this method, you can create large-radius bends or continuous curves. Although it offers a uniform strain distribution across the bend, it might not be as precise as other methods when dealing with specific angles.

To mitigate common issues such as cracking or overbending, it’s essential to:

After bending 304 stainless steel flat bars, finishing and treatment can have a significant impact on the final product’s quality and durability. In order to enhance the appearance of the material, deburring and polishing are crucial steps. Depending on the application, mechanical deburring, electrochemical processes, and manual filing can be used.

In order to relieve internal stresses caused by bending, heat treatment, such as annealing, is often necessary. Steel is heated to a specific temperature and cooled slowly, restoring its formability and reducing the chance of future cracks.

The final design may require further machining or welding. It’s important to consider that these processes can alter the material’s properties.

To maintain corrosion resistance, select filler materials that are compatible with the welding process. Select tools and parameters that take the work-hardened state of stainless steel into account if additional machining is required.

The ability to bend and form 304 stainless steel flat bars is a valuable metalworking skill. Precision and durable bends can be achieved by understanding the material’s properties and applying appropriate techniques.

With Speciality Metals, your project will be supported from conception to completion with high-quality materials, like 304 stainless steel flat bars.

Whether you’re designing intricate designs or fabricating robust components, our guides intend to help you realise your vision with confidence, ensuring marvelous results.

We are working through our full list of FAQs to create blogs and help articles that aim to inform and assist.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options