- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Aluminium Sheet for Vehicles: A Practical Guide to Modifications

Upgrading vehicles for performance, practicality, or style often requires the right material choice. When balancing weight, strength, and versatility, few materials match the benefits of aluminium sheet for vehicles. Whether you’re converting a campervan, reinforcing a work van, or enhancing a custom trailer, aluminium offers durability without unnecessary bulk.

In this detailed guide, we’ll explore why aluminium is such a popular choice, how to work with it successfully, and what products from Speciality Metals can help you create your perfect vehicle modification.

Aluminium weighs about one-third that of steel, making it ideal for applications where reducing load is essential. In vans, trailers, and electric vehicles (EVs), lighter materials improve acceleration, battery range, fuel efficiency, and overall handling. For EV conversions in particular, our 1050-H14 aluminium sheet is a go-to solution thanks to its light profile and high formability.

Despite its lower weight, aluminium offers impressive strength. Products like our 6082-T6 aluminium sheet provide superior structural integrity, making them perfect for load-bearing panels, trailer bases, or custom tool mounts. It ensures the structure can withstand day-to-day stress without sacrificing stability.

Aluminium forms a natural oxide layer that protects it from rust and degradation. This makes it ideal for outdoor and coastal applications—such as marine trailers, work vans, and surf vans. Our 5251-H22 aluminium sheet provides excellent corrosion resistance with added strength, a favourite for harsh environments.

Aluminium is easy to cut, bend, rivet, and weld with everyday tools. From hobbyist workshops to commercial body shops, it is favoured for its workability. At Speciality Metals, we offer cut-to-size aluminium sheets to minimise wastage and reduce labour time on your build.

✔ Improved fuel economy due to lower weight

✔ Enhanced payload capacity without stressing suspension

✔ No rusting – even in coastal climates

✔ Low-maintenance surfaces that resist dirt and moisture

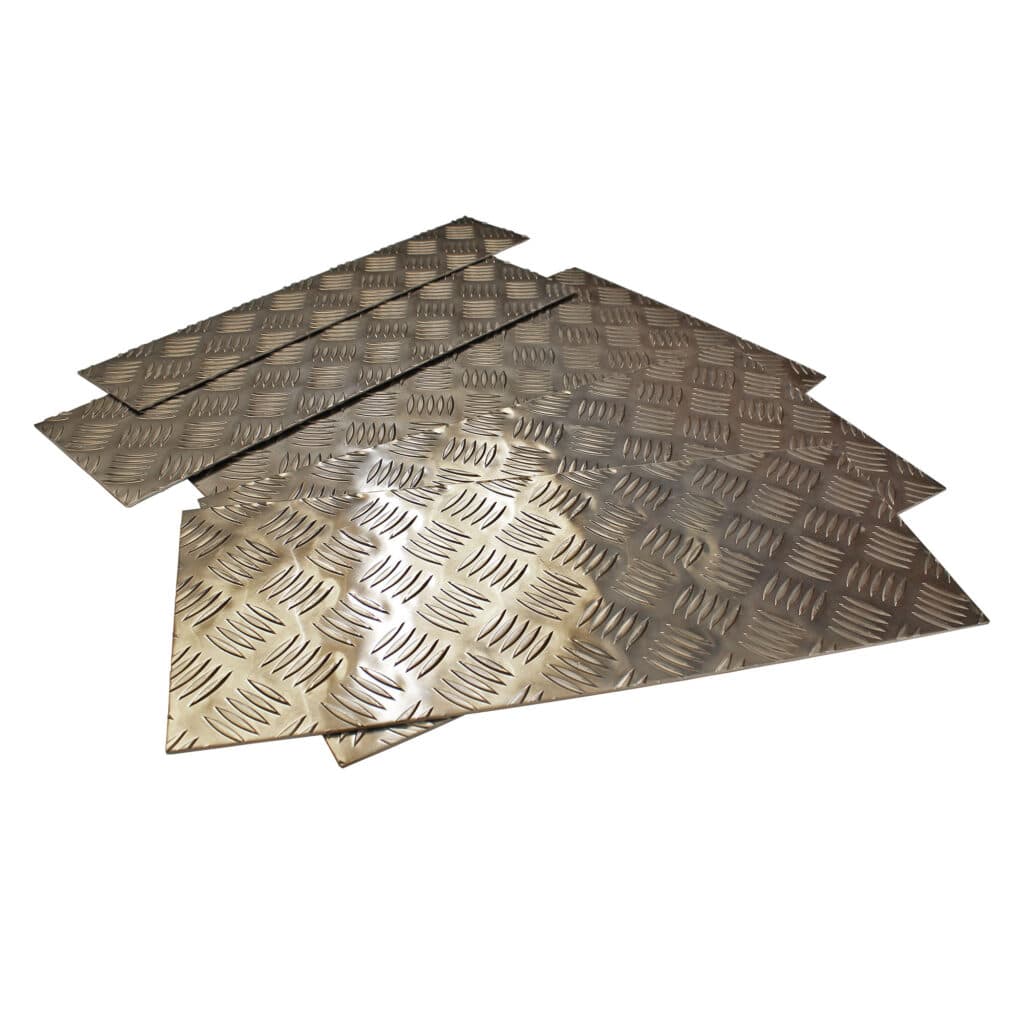

✔ Aesthetic finishes including mill, brushed and tread plate

Aluminium sheet’s flexibility means it’s used across a range of vehicle projects. Our customers regularly use it for:

Interior panelling and walls in campervans

Load-bearing floors in vans and trailers

Roof-mounted racks and ladder supports

Underbody guards and wheel arch linings

Modular tool storage in service vans

External cladding for catering trucks and retail trailers

Insulated panels in mobile offices or labs

If you’re after lightweight, hygienic, and stylish solutions, our brushed and tread plate aluminium sheets provide excellent results.

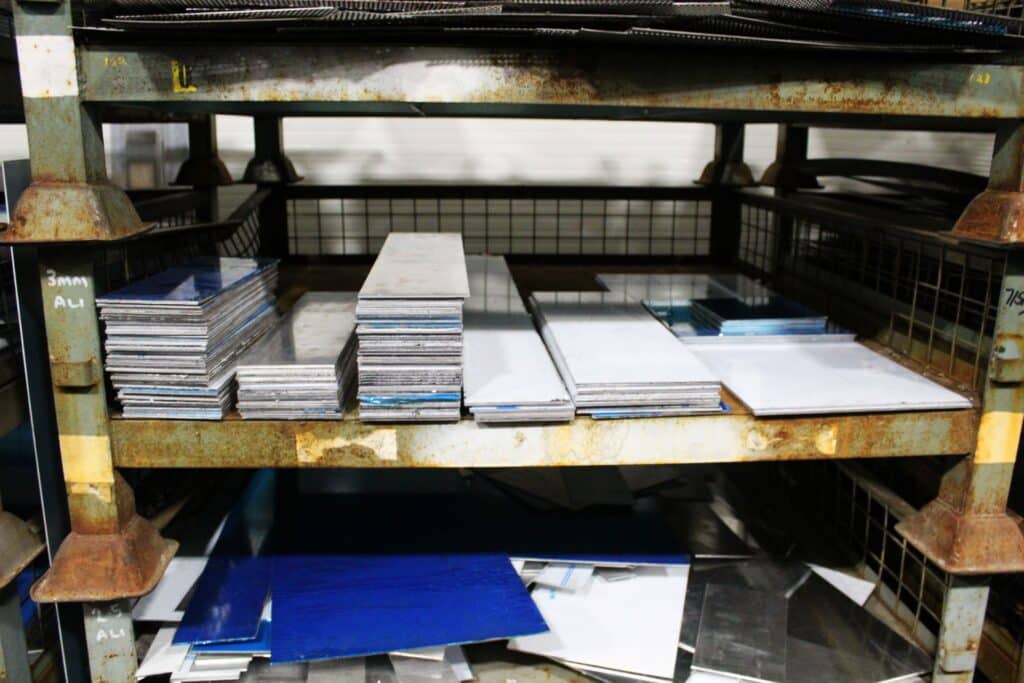

0.8–1.2mm – Interior linings and trim

1.5–2mm – Cladding and light-duty flooring

3–4mm – Load floors and vehicle ramps

5mm+ – Underbody guards and reinforced partitions

1050-H14 – Easy to shape, ideal for van walls and ceilings

5251-H22 – Strong and corrosion-resistant, ideal for floors and outer panels

6082-T6 – Structural strength for rugged use and load-bearing installations

All these are available on Speciality Metals with custom cut options and next-day UK-wide delivery.

Aluminium sheet is now central to:

EV and hybrid vehicle conversions

Van-to-camper transformations

Pop-up shops and exhibition trailers

Field-service vehicles for electricians, plumbers, and mobile groomers

Sustainable and off-grid living builds

We’re seeing increased demand for marine-grade aluminium in coastal regions and rugged tread plate for off-road expedition vehicles. Our range supports both specialist and everyday projects.

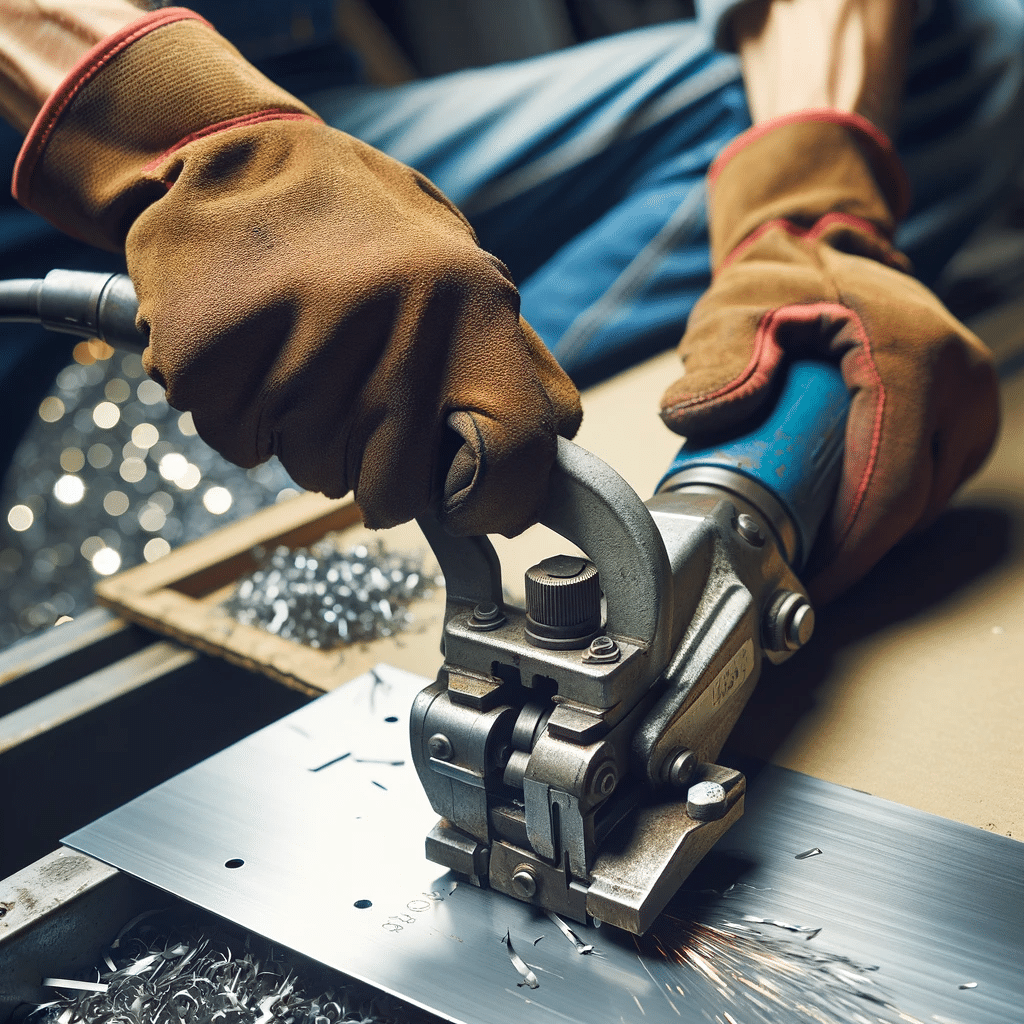

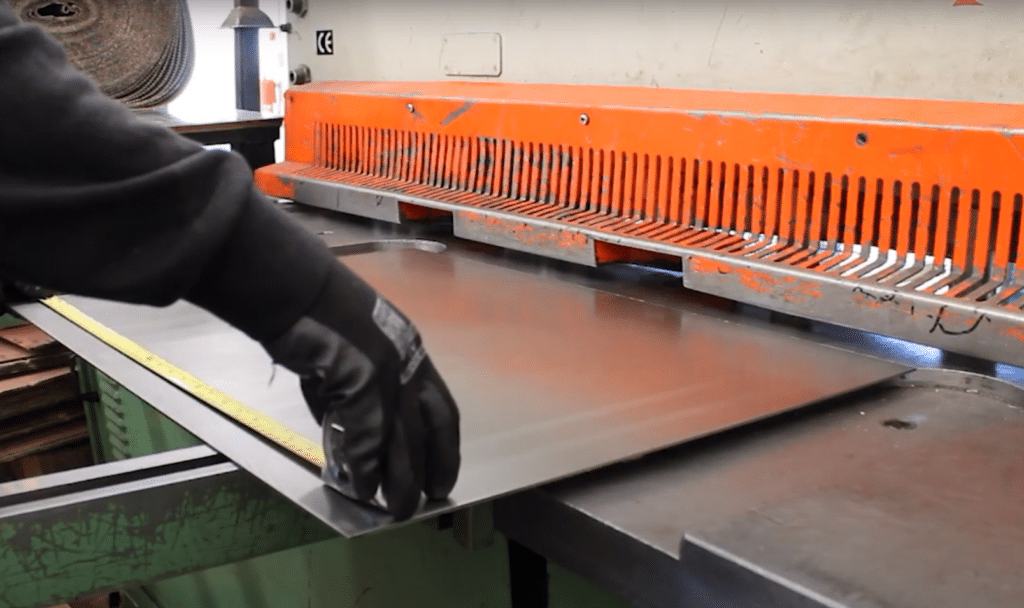

Use jigsaws or circular saws with non-ferrous blades

Secure the sheet firmly to avoid vibration

Lubricate blades for cleaner cuts

Manual brakes work for thin sheets

Hydraulic brakes handle thicker plates

Apply mild heat to reduce cracking on tight curves

TIG and MIG welding for seamless joins

Rivets and structural adhesives for modular/removable designs

Aluminium or stainless fixings to avoid galvanic corrosion

Allow space for expansion with temperature changes

Reinforce stress points like hinges or load areas

Use foam or rubber gaskets for noise reduction

Include drainage paths on roof and side panels

Keep fixings corrosion-resistant for longevity

✘ Using incompatible fixings that cause corrosion

✘ Ignoring weight distribution in floor design

✘ Choosing the wrong thickness for load capacity

✘ Over-tightening bolts on thin sheet areas

At Speciality Metals, customers regularly share their projects:

✔ Campervan fit-outs using 1.2mm 5251-H22 aluminium for durable interiors

✔ Motorcycle trailers lined with 3mm tread plate for grip and protection

✔ Catering vans using polished sheets for hygiene and aesthetics

✔ Scientific survey vans reinforced with 6082-T6 for field stability

✔ Dog grooming vans using lightweight brushed aluminium wall panels

Our team provides expert advice on material selection for each scenario.

Aluminium is low maintenance, but a few simple steps help keep it pristine:

Wash with mild detergent and warm water

Avoid abrasive pads or acidic cleaners

Rinse salt and grime regularly in winter months

Inspect joints and welds seasonally

Wax or polish if you want to retain a bright finish

Aluminium is:

Infinitely recyclable without degradation

Lighter, reducing fuel use and emissions

Cheaper long-term due to rust resistance.

Aligned with UK net-zero vehicle policies

Opting for aluminium from Speciality Metals supports both your vehicle performance and sustainability goals.

To work efficiently with aluminium sheet, consider:

Non-ferrous jigsaw blades

Guillotine cutter or metal shear

Rivet gun and drill bits for soft metals

Brake press for bending

TIG welder for joining

Scriber, ruler, and clamps for layout and accuracy

Our customer service team can advise on tools based on your aluminium choice.

🟢 Trusted UK Supplier with years of metal fabrication expertise

🟢 Cut-to-Size Options available online

🟢 Fast UK-Wide Delivery, including next-day services

🟢 High-Quality Stock in multiple grades and finishes

🟢 Expert Support from knowledgeable staff

Whether you’re a professional fabricator or a DIY builder, you can count on our reliable products and fast service.

Aluminium sheet for vehicles is a proven, high-performance solution for modern modifications. It’s strong, light, corrosion-resistant, and endlessly customisable. From interior linings to load floors, its role in improving vehicle performance and aesthetics is unmatched.

If you’re ready to start your vehicle build or upgrade, explore the full range of aluminium sheet options at Speciality Metals. With the right tools, smart planning, and reliable materials, your project can be lighter, stronger, and better.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.