- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » A Guide to Sheet Metal Plating: Enhancing Appearance and Resistance

Sheet metal plating is a process that has been practiced for centuries, and its advantages have only become more apparent with the development of modern technology. This method is used to coat pieces of sheet metal with another metal, enhancing not only their aesthetic appeal but also their durability and resistance. Whether you’re a hobbyist, a professional in the manufacturing industry, or just someone curious about the process, this guide aims to shine a light on the intricacies and benefits of sheet metal plating.

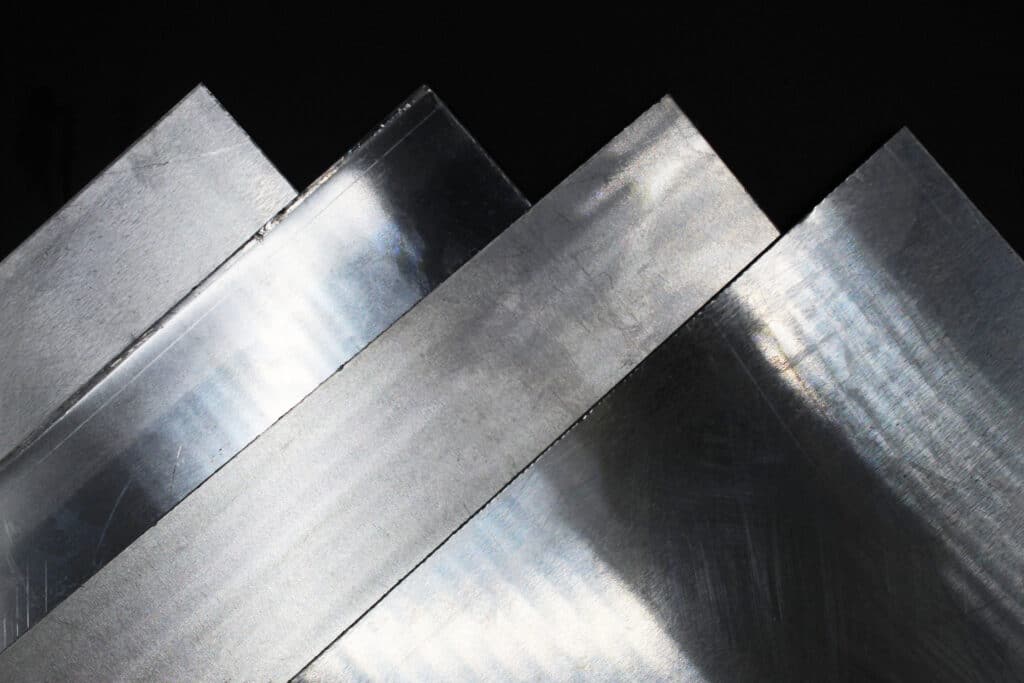

At its core, sheet metal plating involves depositing a thin layer of metal onto the surface of a base metal (or substrate). The goal can be varied: sometimes, it’s to improve the base metal’s appearance; other times, it’s to add characteristics not inherent to the substrate, such as improved corrosion resistance or enhanced electrical conductivity.

The process starts with preparing the base metal. This involves cleaning the surface to ensure that it is free from any dirt, oil, or other contaminants. Next, the sheet metal is submerged in a bath containing a solution of the metal to be plated. Through a series of chemical and electrical processes, the desired metal is then deposited onto the sheet metal’s surface.

1. Enhanced Appearance:

One of the most noticeable advantages of sheet metal plating is the dramatic improvement in the metal’s appearance. A plated finish can give a shiny, mirror-like appearance or a subtle matte finish, depending on the type of metal and the process used. This is especially beneficial for decorative objects, jewelry, and fixtures that need an appealing finish.

2. Increased Resistance:

Sheet metal plating provides a barrier between the base metal and the environment. This barrier can be resistant to various elements, such as oxidation, rust, or even chemicals. For instance, chrome plating on car parts can prevent rusting and maintain a shiny appearance for years.

3. Added Durability:

The plated layer can also add hardness to the sheet metal, making it more resistant to wear and tear. This is particularly beneficial for parts that are subjected to regular friction or movement.

4. Improved Conductivity:

Certain metals, like copper or gold, are excellent conductors of electricity. By using sheet metal plating to add a thin layer of these metals, electrical conductivity can be improved, which is essential for electronic components.

Gold: Known for its excellent conductivity and resistance to tarnish, gold plating is frequently used in electronic connectors and for decorative purposes.

Silver: While it tarnishes more easily than gold, silver is often used for its superior electrical conductivity, especially in electronic components.

Nickel: Nickel provides a durable and lustrous finish. It’s commonly used in various applications, from automotive parts to kitchenware. It also serves as a base layer in many other plating processes because of its excellent adhesion properties.

Copper: Often used as an underlayer for other types of plating, copper provides excellent electrical conductivity. It’s commonly used on printed circuit boards and in some decorative applications.

Zinc: Zinc plating is employed to provide a corrosion-resistant layer, especially on steel. This is often seen on hardware and automotive components to protect against rust.

Chrome: Known for its shiny finish, chrome plating is used for decorative purposes, as well as to provide a durable, wear-resistant surface. It’s popular for car parts, bathroom fixtures, and many other applications.

Tin: This is often used for its solderability and corrosion resistance. Tin plating is commonly found on components like electronic connectors.

Palladium: With properties similar to gold but at a lower cost, palladium is sometimes used in electronic applications.

Rhodium: This metal is prized for its brilliant white shine and resistance to tarnish. It’s frequently used in jewelry and for optical instruments.

Platinum: Used for its excellent resistance to wear and tarnish, platinum is often employed in high-end applications, including jewelry and certain industrial applications.

Construction: Sheet metal plate is extensively used in building construction. It is utilised for roofing, cladding, flashings, rainwater goods like gutters and downpipes, and architectural features.

Automotive Industry: Cars, trucks, and other vehicles use sheet metal plates for various components, including body panels, chassis, and internal structures.

Aerospace: Aircraft bodies and wings are often made from specially engineered sheet metal plates that are both lightweight and durable.

Consumer Goods: Many household items, including appliances like refrigerators, ovens, washing machines, and dryers, are made using sheet metal plates.

Industrial Machinery: Sheet metal plates are molded and shaped into various components of machinery and equipment.

Military: Armored vehicles, ships, and other defense-related equipment often utilise heavy sheet metal plates for protection.

Food Industry: Commercial food equipment, counters, and storage units in restaurants often use stainless steel sheet metal due to its hygienic properties.

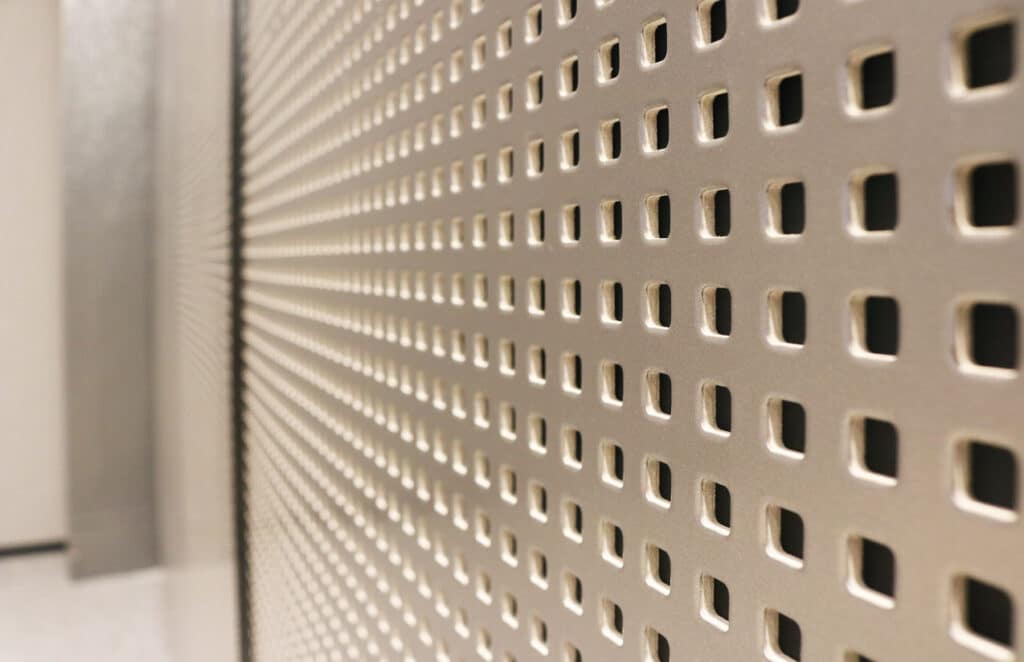

Electronics: Sheet metal is used in making casings for electronics, racks for server rooms, and other associated components.

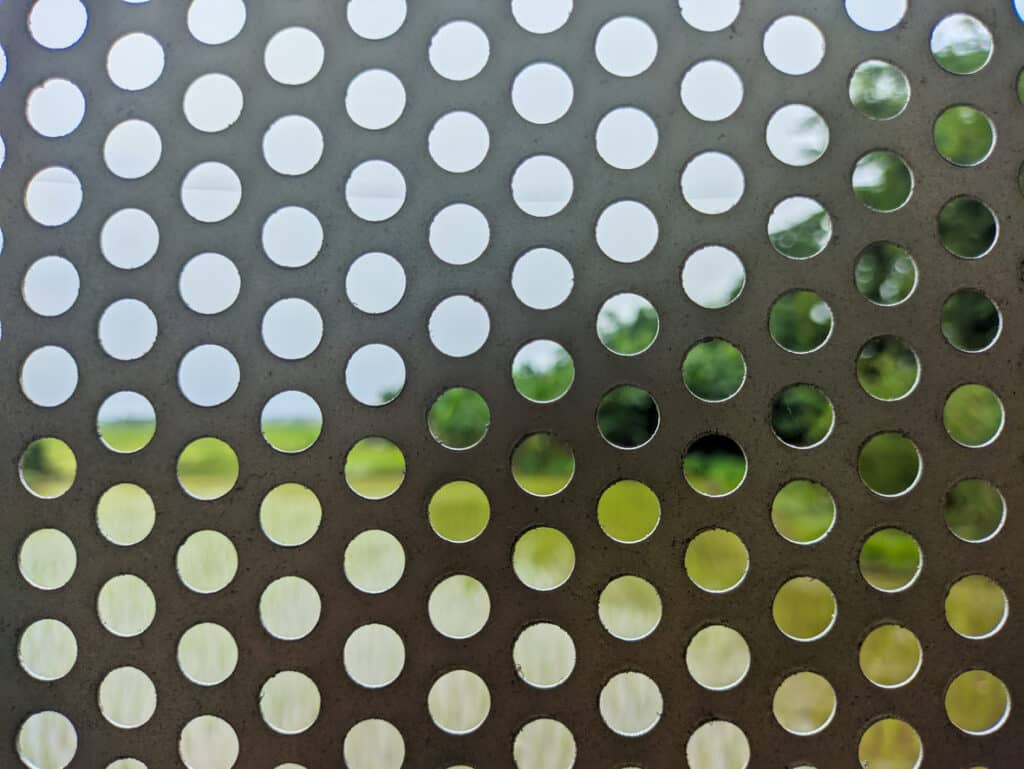

HVAC: Heating, Ventilation, and Air Conditioning systems rely heavily on sheet metal for ductwork and other related components.

Art and Sculpture: Sheet metal plates can be shaped into various artistic creations, from modern art installations to public sculptures.

Energy: In the renewable energy sector, particularly in solar energy, sheet metal plates can be used as structural components for mounting panels or as reflectors.

Medical: Stainless steel sheet metal, due to its non-reactive properties, is often used in creating medical tools and equipment.

While sheet metal plating offers numerous benefits, it’s also essential to consider its environmental impact. Some plating processes can produce harmful by-products or utilise chemicals that can be detrimental to the environment. It’s crucial to ensure that any plating is done responsibly, adhering to safety and environmental standards. Moreover, recent advancements have paved the way for greener plating methods, which reduce or eliminate the use of harmful substances.

Safety First:

Methods:

Hand Shears: Suitable for thin plates. Simply mark your cut lines and use the shears to cut along the line.

Hacksaw: Useful for thicker plates. Make sure the metal plate is securely clamped before cutting.

Circular Saw: Equipped with a metal cutting blade, it can provide straight cuts on thicker metal plates.

Angle Grinder: With a cut-off wheel, it’s versatile for cutting metal plates. Always ensure you’re using the right type of disc for the material you’re cutting.

Plasma Cutter: For even thicker plates or when precision cuts are needed, a plasma cutter is very efficient. It uses an electric arc and compressed air to cut through metal.

Water Jet Cutting: This uses a high-pressure stream of water, sometimes with abrasives, to make precision cuts. It’s typically used in industrial settings.

Safety First:

Methods:

Manual Bending with a Hammer: For thin plates, mark the bend line, securely clamp the metal plate over the edge of a workbench or similar surface, and use a hammer to bend the metal over the edge to the desired angle.

Bending Brake: This is a device specifically designed to make bends in metal plates. They come in various sizes and capabilities, from small manual brakes for thin metals to large hydraulic brakes for thick plates.

Vise and Hammer: Clamp the plate in a large vise with the bend line right at the top of the vise jaws. Using a hammer or mallet, bend the metal plate to the desired angle.

Roll Benders: These are used when you want to create a curved bend rather than a sharp angle. The metal plate is passed between three rollers to produce a curve.

Press Brake: Typically used in industrial settings, a press brake can apply a significant amount of force to bend thick metal plates.

Heat: For very thick plates or to make the bending process easier, sometimes heat is applied using a torch. This makes the metal more malleable. If using heat, always ensure proper ventilation and avoid breathing in fumes.

Sheet metal plating is more than just a process; it’s an art that combines science, technology, and craftsmanship. By understanding the basics and benefits of this technique, we can appreciate the beauty and functionality it brings to countless items in our everyday lives. Whether for enhancing appearance, resistance, or both, sheet metal plating remains an invaluable technique in the world of manufacturing and beyond.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about ‘Metal Steel Sheet or Steel Plate? A Guide to Understanding the Differences‘ and ‘The Fundamentals of Welding on Sheet Metal and Other Metal Materials‘ recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options