- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » A Deep Dive into 304L Grade Stainless Steel Angles: Performance in Harsh Environments

In construction and industrial design, the choice of materials can significantly impact the integrity and longevity of a project.

Among these, 304L grade stainless steel angles stand out for their resilience and versatility, marking their importance across various industries. They are one of our core materials across our various channels.

Known for their robustness against corrosion and ability to perform under challenging conditions, these stainless steel angles have become indispensable in modern engineering and architectural applications.

In this article, we dive deep into the attributes of 304L grade stainless steel angles, exploring their suitability and performance in harsh environmental conditions. By understanding the properties that make these angles a preferred choice, we can appreciate their critical role in various applications, from intricate architectural structures to demanding industrial setups.

Let’s go…

An austenitic alloy, stainless steel 304L grade has garnered wide acclaim for its efficiency and durability. The ‘L’ in its name indicates that it has a lower carbon content than its 304 counterpart, which primarily consists of iron, chromium, and nickel. A reduced carbon content enhances the metal’s weldability and minimises corrosion risk following welding, a critical factor in many industrial applications.

Due to its high chromium content, 304L stainless steel has exceptional corrosion resistance. Environments prone to rust and degradation, such as coastal areas or areas with high humidity, benefit from this property. Nickel also contributes to its overall resistance to corrosive substances, so it is a reliable choice for various chemical exposure scenarios.

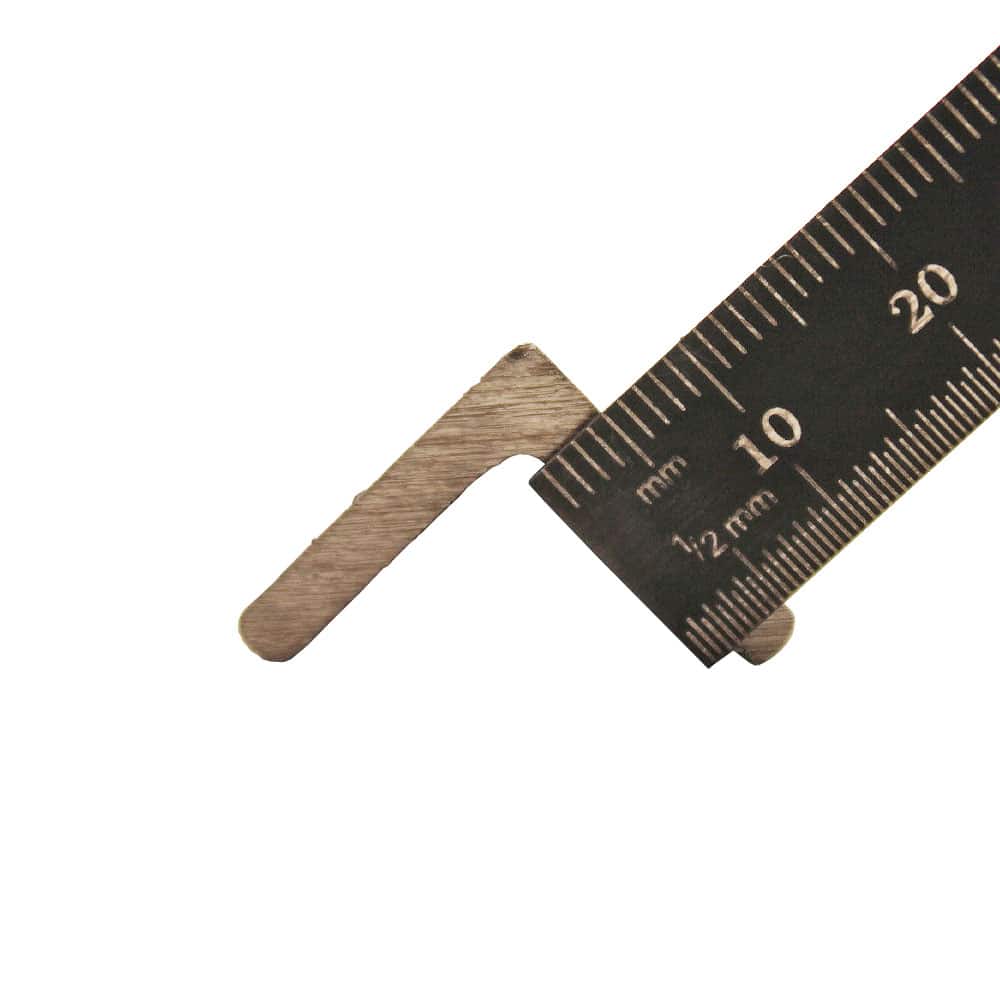

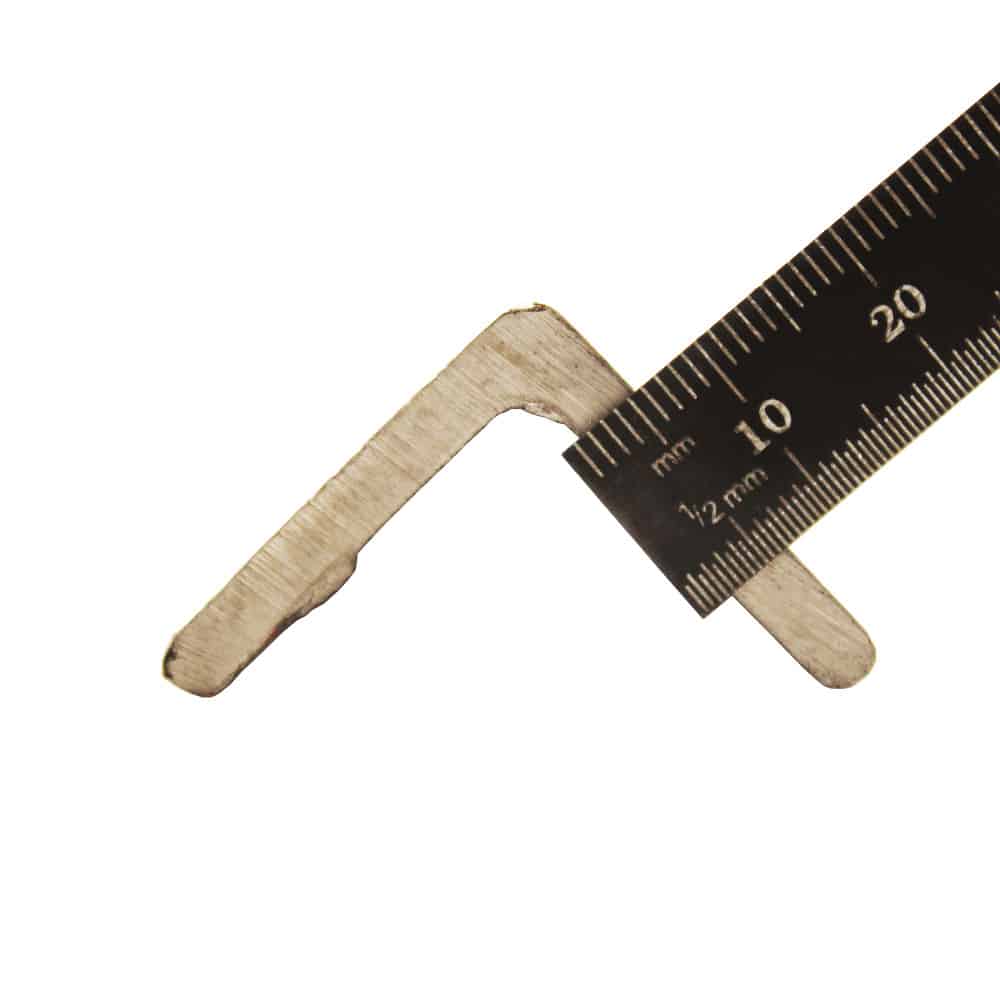

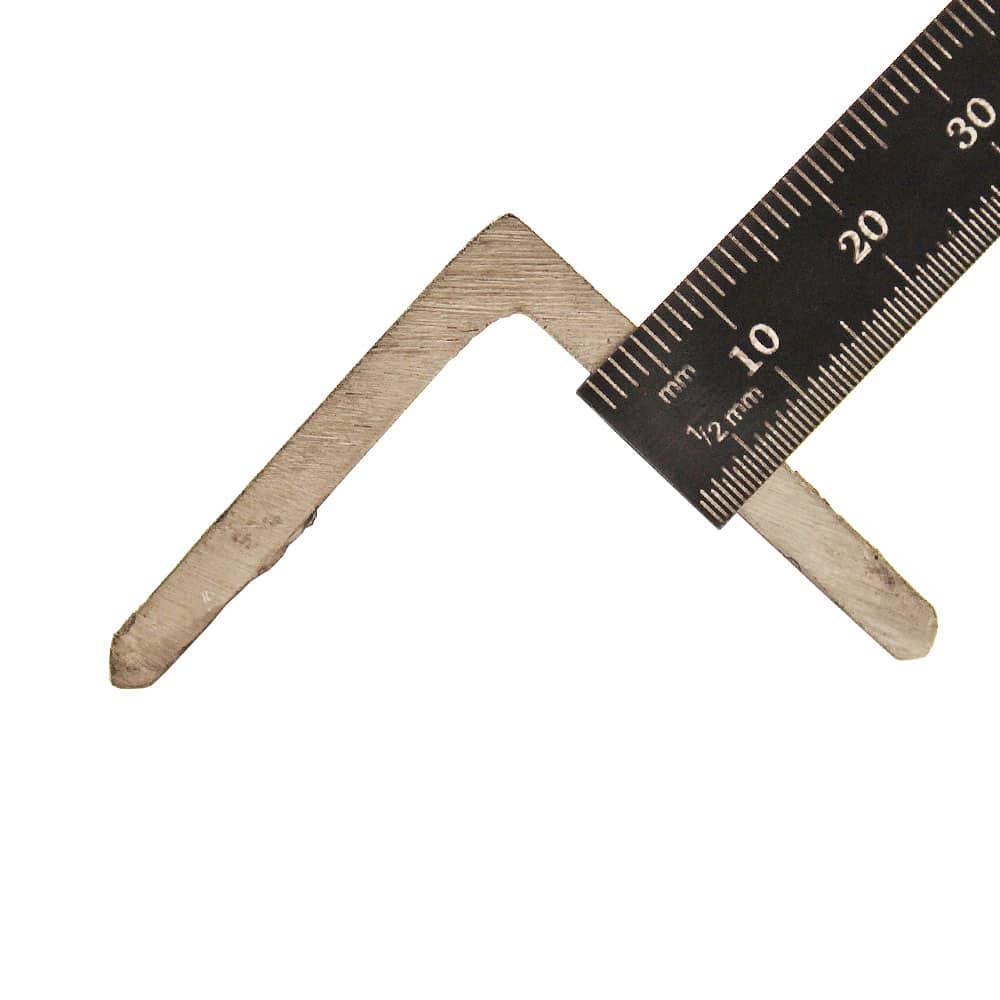

Speciality Metals offers 304L stainless steel angles in diverse sizes, including 50mm x 50mm x 3mm, 20mm x 20mm x 3mm, 30mm x 30mm x 3mm, and 40mm x 40mm x 3mm, catering to a wide array of applications.

Each size serves a specific purpose, ranging from structural support in buildings and bridges to detailed finishing in interior designs. The 50mm x 50mm x 3mm angle, for instance, is robust enough for major construction projects, while the 20mm x 20mm x 3mm variant is ideal for decorative trims and finishing touches. This versatility not only underscores the practicality of 304L grade stainless steel but also showcases the adaptability of Speciality Metals’ offerings to meet diverse industrial and architectural needs.

Here are some standard uses for this type of metal:

Building Frames: They are often used in the construction of building frames, providing essential support and stability, thanks to their robustness and resistance to environmental factors.

Lintel Beams: In architectural designs, 304L stainless steel angles are ideal for lintel beams over doors and windows, offering both structural support and resistance to weathering.

Trailers and Truck Bodies: The automotive industry utilises these angles in the manufacturing of trailers and truck bodies for their ability to endure heavy loads and resist corrosion.

Racking and Shelving Systems: In warehousing and storage, they are employed to create sturdy and durable racking systems, capable of handling significant weight without bending or warping.

Furniture Framework: Due to their aesthetic appeal and strength, these angles are also popular in designing and constructing metal frames for furniture.

Protective Edges and Trims: In both industrial and residential settings, 304L stainless steel angles are used as protective edges or trims, safeguarding surfaces against wear and tear.

Equipment Frames in Food Processing: Given their non-reactive nature, these angles are safe for framing equipment in food processing plants, preventing contamination and withstanding rigorous cleaning protocols.

Custom Fabrications: Their ease of fabrication means they can be cut, bent, and welded into various custom shapes and structures, fitting diverse custom project needs.

As specialists in all forms of metals, we can vouch for the fact that harsh environments can challenge the integrity and longevity of all materials.

In these environments, corrosion is common, extreme temperatures are common, continuous chemical exposure is common, and mechanical stress is common. In such settings, resilient materials are not only desirable but essential to safety and performance.

304L stainless steel is particularly suitable for these demanding environments because of its unique composition and properties. Due to its low carbon content and significant chromium content, the alloy is exceptionally corrosion-resistant. Corrosive elements such as saltwater in marine applications or corrosive chemicals in industrial plants are a daily challenge for this type of resistance. In the alloy, chromium forms a passive layer of chromium oxide that prevents rust and corrosion. When scratched or damaged, this layer will reform and continue to protect the steel.

At low temperatures, 304L stainless steel maintains its strength and does not become brittle, making it suitable for use in cold environments. Its durability makes it ideal for settings where mechanical wear and tear are common. A combination of corrosion resistance and durability makes 304L stainless steel angles an ideal choice for harsh environmental conditions, ensuring a long lifespan and reducing the need for frequent maintenance.

In Industrial Settings, 304L stainless steel angles are extensively used in chemical plants and processing facilities. Materials in these environments are often exposed to aggressive chemicals and varying temperatures. Due to its chemical stability and temperature resilience, 304L is ideal for supporting structures, piping systems, and protective barriers. 304L stainless steel’s resistance to saltwater corrosion makes it ideal for marine applications. In shipbuilding, harbor installations, and offshore oil rigs, the metal’s resistance to saltwater and harsh weather conditions is essential.

In the Construction Industry, the role of 304L stainless steel angles cannot be overstated, especially in projects exposed to corrosive elements. It includes buildings in coastal areas with salt spray or in industrial zones with chemical exposure. This construction is stable and long lasting due to the strength and corrosion resistance of 304L stainless steel. Additionally, its aesthetic appeal makes it a popular choice for visible structural elements and decorative accents.

The Automotive and Aerospace Industries also capitalise on the advantages of 304L stainless steel. Automotive applications include framing, structural supports, and exhaust systems, where resistance to high temperatures and corrosive exhaust gases is crucial. In the aerospace industry, 304L stainless steel is used in the construction of frames and supports for aircraft that need to withstand high altitudes and fluctuating temperatures. Vehicles and aircraft must be able to maintain structural integrity under extreme conditions in order to be safe and perform well.

In all these applications, 304L stainless steel angles from Speciality Metals, with their assured quality and diverse size range, can provide an optimal solution for projects demanding reliability and durability in challenging environments.

A selection of 304L stainless steel angles from Speciality Metals comes with a number of advantages, ensuring not only superior products but also comprehensive service that addresses the specific needs of clients. Partnering with Speciality Metals means partnering with a company that is unwaveringly committed to quality assurance. As each 304L stainless steel angle is produced to meet stringent standards, Speciality Metals ensures its durability and resilience.

Speciality Metals offers a wide variety of sizes, meeting the needs of a wide range of industries. A range of sizes is available, from 50mm x 50mm x 3mm to smaller dimensions like 20mm x 20mm x 3mm, to suit various applications in construction, automotive, or aerospace. Because of this versatility in size, clients can find the perfect fit for their specific project needs without requiring extensive modifications.

Speciality Metals also offers a rapid delivery service, which is a significant advantage, especially in industries where time is of the essence. With an understanding that delays can be costly, Speciality Metals ensures that clients receive their orders on time, facilitating smoother project timelines and efficient task completion.

Through its wide range of 304L stainless steel angles, Speciality Metals not only provides a product, but also delivers reliability and performance. A customer-centric approach, combined with their expertise in stainless steel, makes us a preferred choice for businesses and DIY enthusiasts alike.

Maintaining 304L stainless steel angles in harsh environments requires attention to detail to ensure longevity and preserve the metal’s integrity. To prevent galvanic corrosion, it is crucial to use compatible fastening materials when installing these angles. To match the corrosion resistance of the angles, stainless steel fasteners are recommended. As well, ensure that the surfaces where the angles will be mounted are clean and stable.

In environments exposed to chemicals or saltwater, regular cleaning is vital to prevent buildup of corrosive substances. Avoid abrasive materials and mild detergents that can damage the surface. Areas exposed to corrosive elements should be cleaned more frequently.

Periodically inspect the angles for signs of wear and corrosion. Early detection of potential issues can prevent more serious damage and extend the metal’s lifespan. A light buffing can restore the protective chromium oxide layer after minor surface damage or scratches.

304L stainless steel angles will perform better and last longer if you follow these installation and maintenance tips.

304L stainless steel angles from Speciality Metals are an excellent choice for use in harsh environments, combining superior corrosion resistance, durability, and versatility. Due to this, they are suitable for a wide range of industrial applications, including construction, automotive, aerospace, and marine. Every stainless steel angle supplied by Speciality Metals is of the highest quality, meets rigorous standards, and comes in a variety of sizes to meet diverse project requirements.

For businesses seeking materials that can withstand harsh conditions, Speciality Metals’ expertise in providing 304L stainless steel angles is unmatched. Our commitment to quality, customer satisfaction, and timely service makes Speciality Metals a leader in the metal supply industry.

Whether you are undertaking a large-scale industrial project or require specific sizes for specialised applications, we are here to provide the solutions you need.

For custom orders or more information about our products and services, please contact us. Our team is ready to assist you with your requirements and help you find the perfect metal solutions for your projects.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options